A flexible up-conversion red light sensor for living body and its preparation method

A sensor and red light technology, applied in the field of biotechnology and materials, can solve the problems of high demand, large metabolic burden of the living body, weakened luminous efficiency, etc., and achieve the effects of high biological safety, low biological toxicity, and high scientific research application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

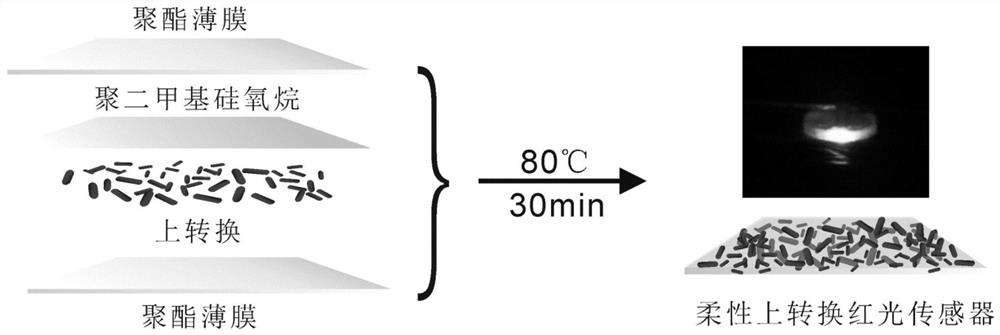

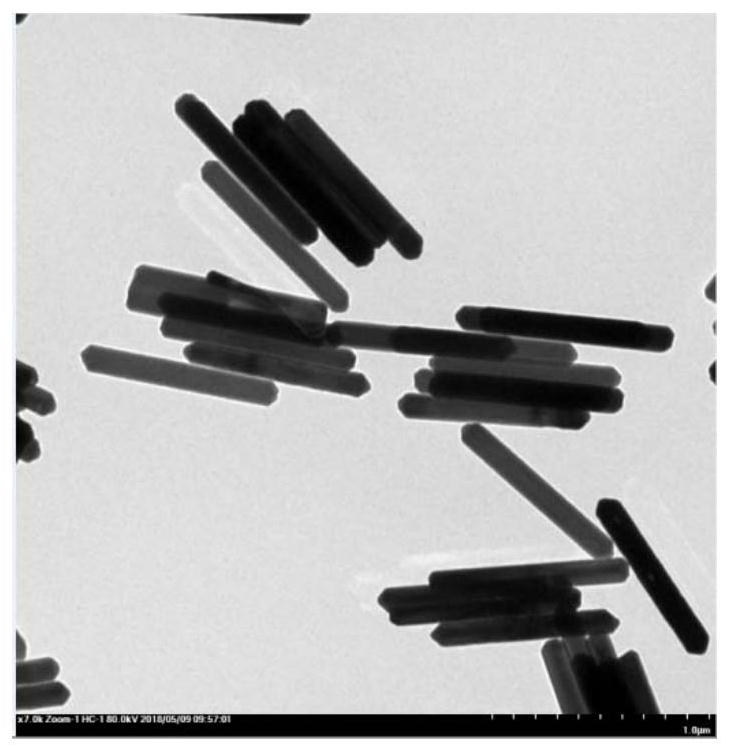

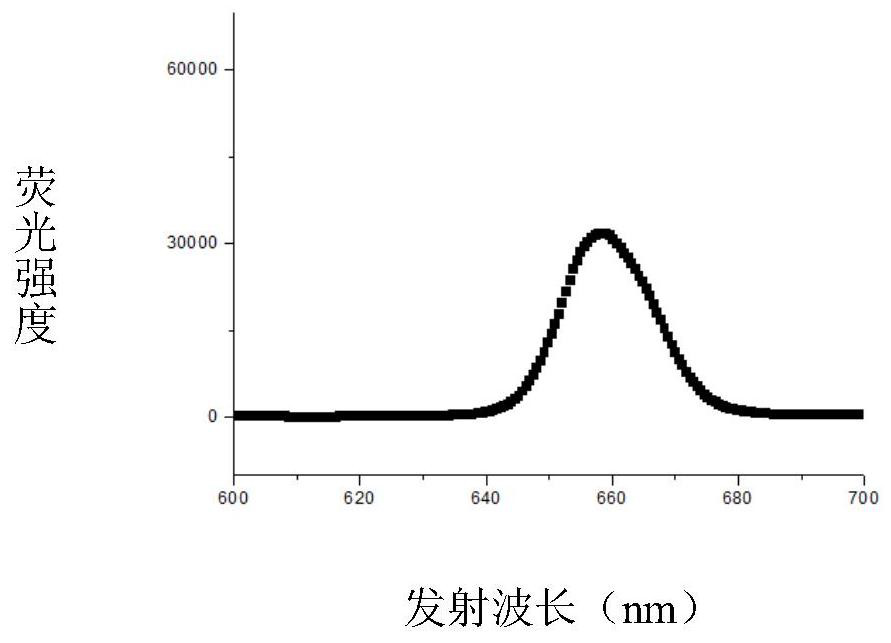

[0027] Fabrication of flexible up-conversion red light sensor for living body

[0028] Pre-lay a layer of polyester film on a glass sheet, configure a 10:1 polydimethylsiloxane precursor, and mix it with a red light-emitting up-conversion microrod doped with rare earth erbium element 10mg / ml, negative pressure 0.03MPa Vacuumize for 30 minutes to remove air bubbles, and evenly spin-coat the mixture on the polyester film. After the liquid film is 0.2mm thick, solidify in a vacuum at 80°C for 30 minutes. After it cools down, lay a layer of polyester film on the top layer to avoid air bubbles ( figure 1 ).

Embodiment 2

[0030] Fabrication of flexible up-conversion red light sensor for living body

[0031] Pre-lay a layer of polyester film on a glass sheet, configure a polydimethylsiloxane precursor with a ratio of 9:1, and mix it with a red light-emitting up-conversion microrod doped with rare earth erbium element 10mg / ml, negative pressure 0.03 Vacuum at MPa for 40 minutes to remove air bubbles, and evenly spin-coat the mixture on the polyester film. After the liquid is formed into a film of 1mm, it is cured at 80°C for 40 minutes at a high temperature. After cooling, lay a layer of polyester film on the top layer to avoid air bubbles.

Embodiment 3

[0033] Fabrication of flexible up-conversion red light sensor for living body

[0034] Pre-lay a layer of polyester film on a glass sheet, configure a polydimethylsiloxane precursor with a ratio of 7:1, and mix it with red light emitting up-conversion microrods doped with rare earth erbium element 100mg / ml, negative pressure 0.03 Vacuum at MPa for 40 minutes to remove air bubbles, and evenly spin-coat the mixture on the polyester film. After the liquid is formed into a film of 3mm, it is cured at 80°C for 60 minutes at a high temperature. After cooling, lay a layer of polyester film on the top layer to avoid air bubbles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com