A mineral flotation foam image color correction method and a foam color detection system

A foam image and color correction technology, applied in image analysis, image data processing, biological neural network models, etc., can solve problems such as limited scope and incomplete solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

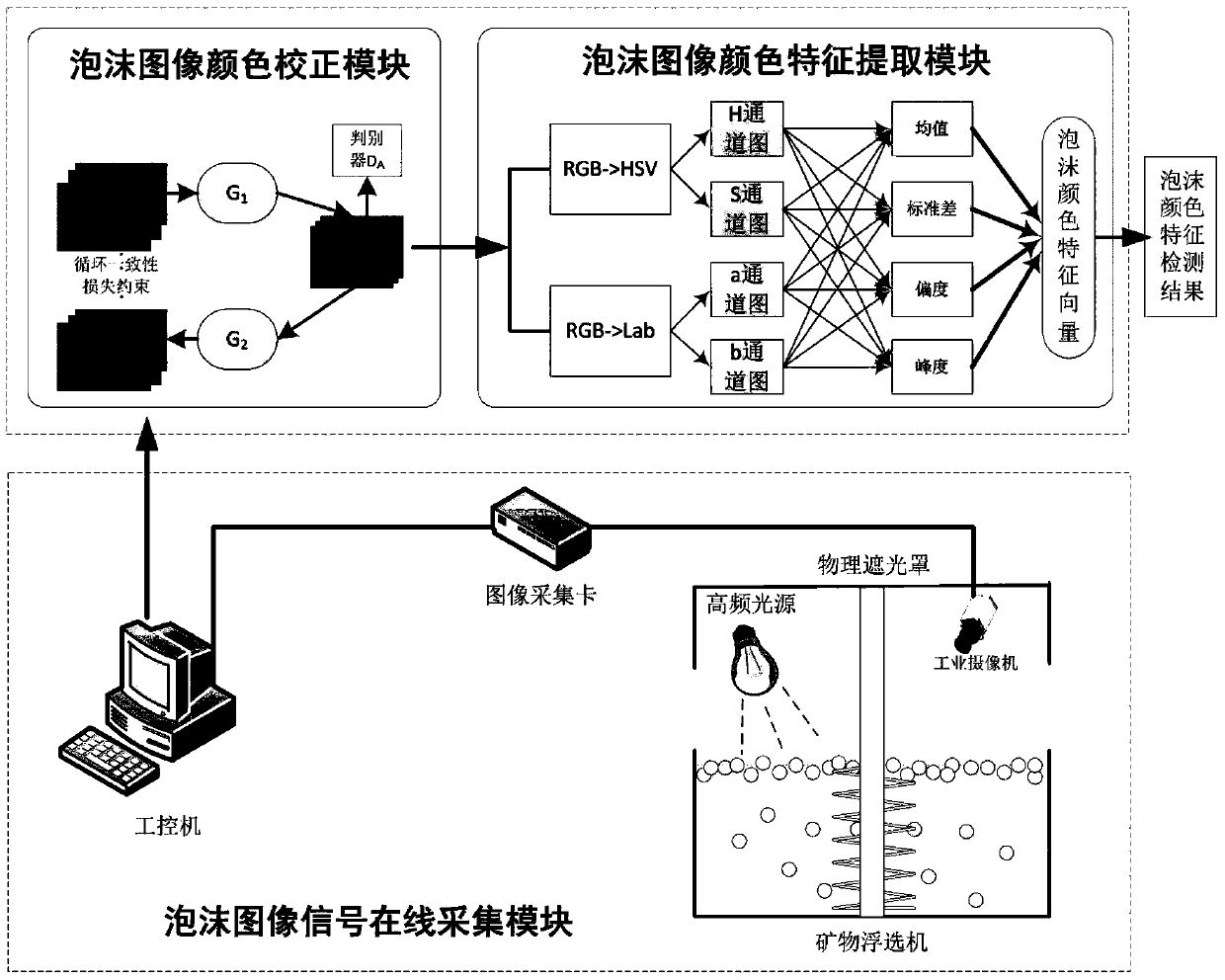

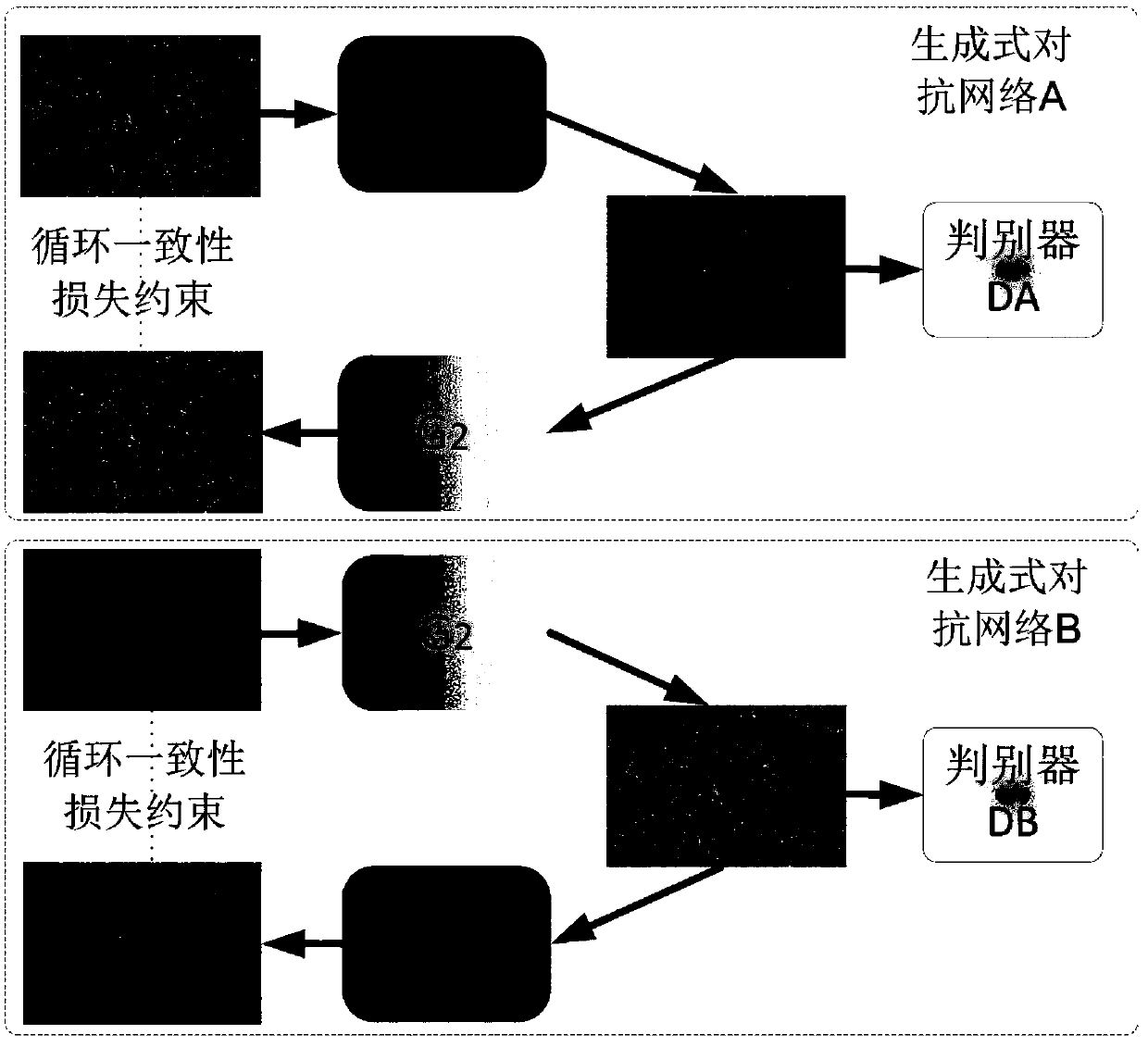

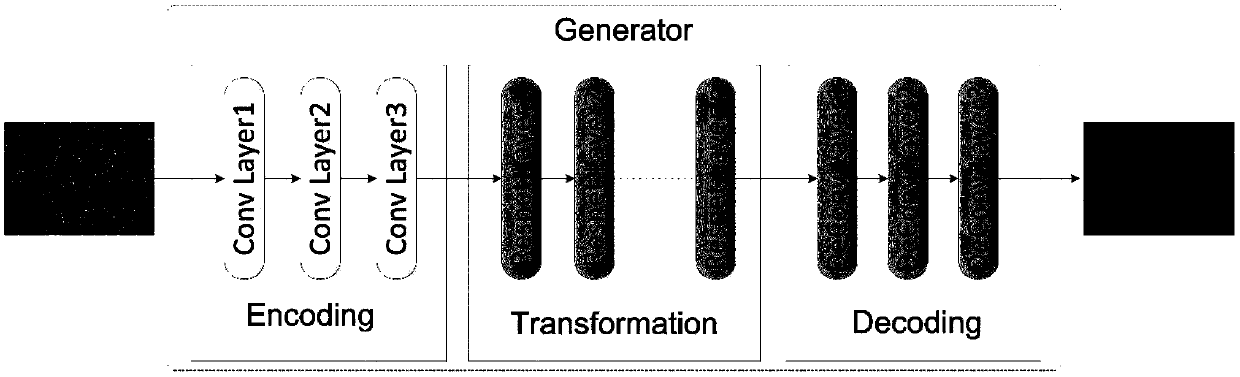

[0052] The invention provides a mineral flotation froth image color correction method and a froth color detection system. The invention can well map the color of the froth image under unknown light (with color shift) to the color display under the reference color gamut, Effectively improves the accuracy of the foam color feature extraction of the mineral flotation process monitoring system based on machine vision, and the foam image color correction method provided by the invention has fast color correction speed and supports online model correction, which can adapt to various unknown working conditions Effective correction of image color under different types of foam. The method and system include the following steps:

[0053] S1: Build an online foam image signal acquisition module, which consists of an industrial computer, a high-frequency light source, an industrial camera, and an image acquisition card; among them, the high-frequency light source and the industrial camera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com