Heat pump drying room

A technology of heat pump drying and drying room, which is applied in drying, drying machine, tobacco drying, etc., can solve the problems of large flow resistance, loss of flavor substances, and decline in the quality of flue-cured tobacco, so as to reduce the drying air temperature, Uniform drying speed and improved quality of flue-cured tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

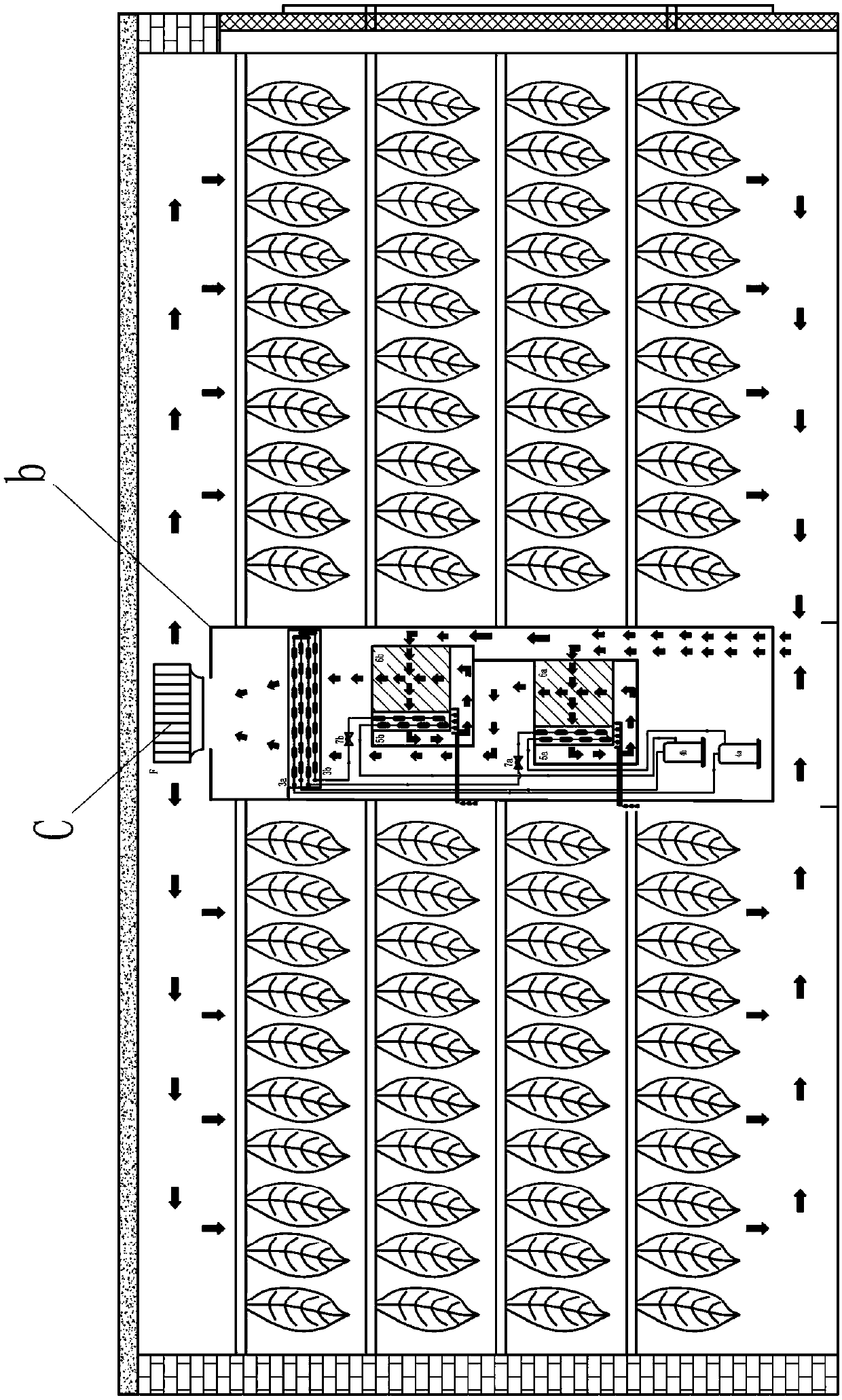

[0070] Referring to 2-5, in this embodiment, the heat pump drying room includes a drying room a, and the drying room a is a drying room with a square cross section. Of course, in other embodiments, the cross-section of the drying house can also be rectangular or other polygonal, which is not limited here.

[0071] In this example, if Figure 3-4 As shown in , a heat pump drying system is set in the center of the drying house a, and the heat pump drying system includes a group of heat pump units b and a centrifugal fan c arranged at the air outlet on the top of the heat pump unit b.

[0072] In this example, refer to Figure 5 In this embodiment, the heat pump unit includes a casing 1, which is a vertical rectangular casing. The housing 1 includes two sets of dehumidification systems, respectively the first dehumidification system and the second dehumidification system; the first dehumidification system includes a sequentially connected compressor 4a, evaporator 5a, throttlin...

Embodiment 2

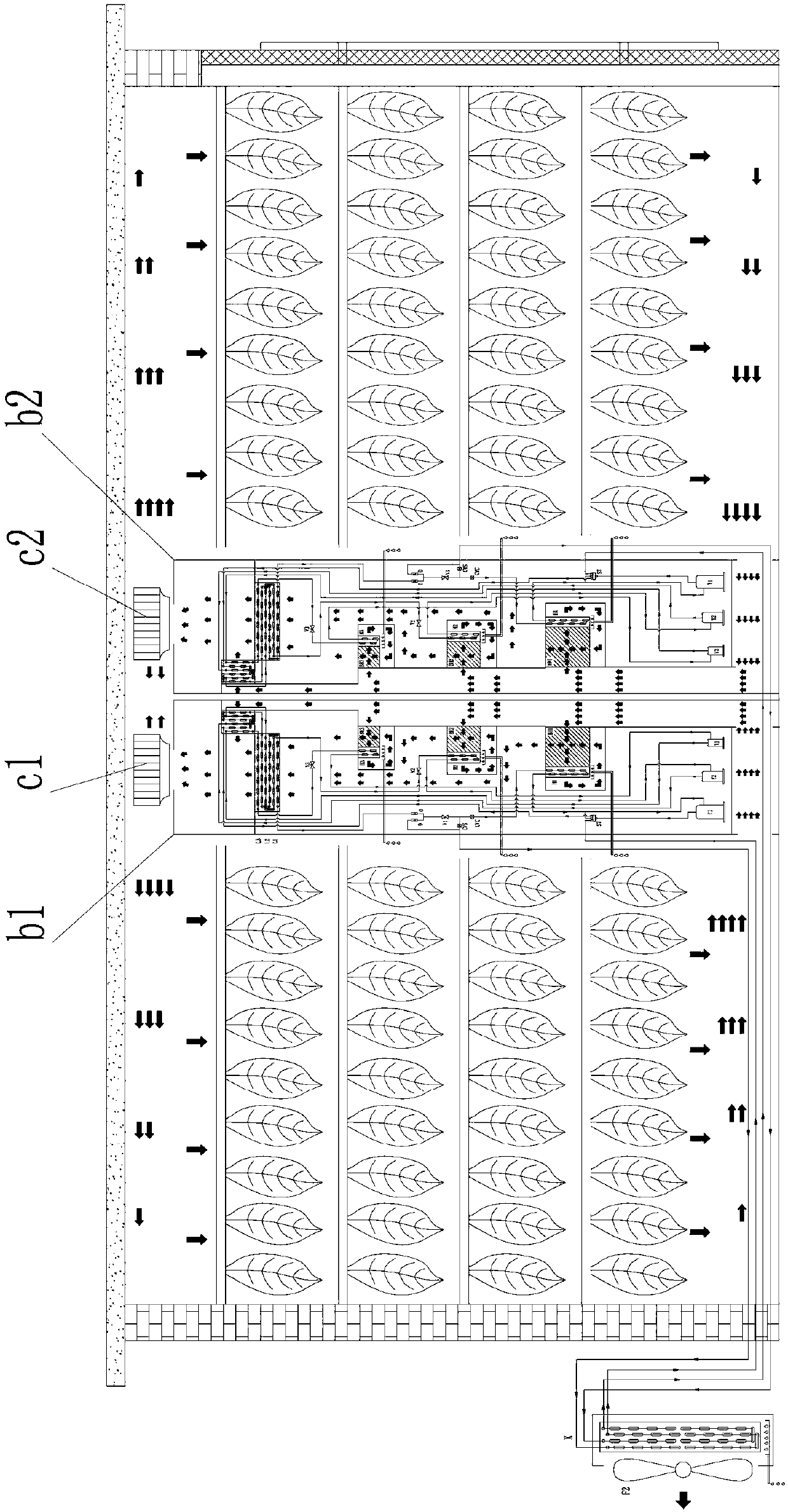

[0079] refer to Figure 6-9 , in this embodiment, a heat pump system is arranged in each drying room a, and each heat pump system includes two sets of heat pump units, which are respectively heat pump unit b1 and heat pump unit b2; heat pump unit b1 and heat pump unit b2 are arranged side by side Set directly at the central position of the drying room a.

[0080] In this embodiment, the heat pump unit b1 and the heat pump unit b2 are provided with air outlets at the upper ends and air inlets at the lower ends, a centrifugal fan c1 is installed at the air outlet at the upper end of the heat pump unit b1, and a centrifugal fan c1 is installed at the air outlet at the upper end of the heat pump unit b2. A centrifugal fan c2 is provided; the high-temperature drying medium produced by the heat pump unit b1 and the heat pump unit b2 diffuses in the centrifugal fan c1 and the centrifugal fan c2 to form a top air bag on the inner top of the drying room a, and then the high-temperature...

Embodiment 3

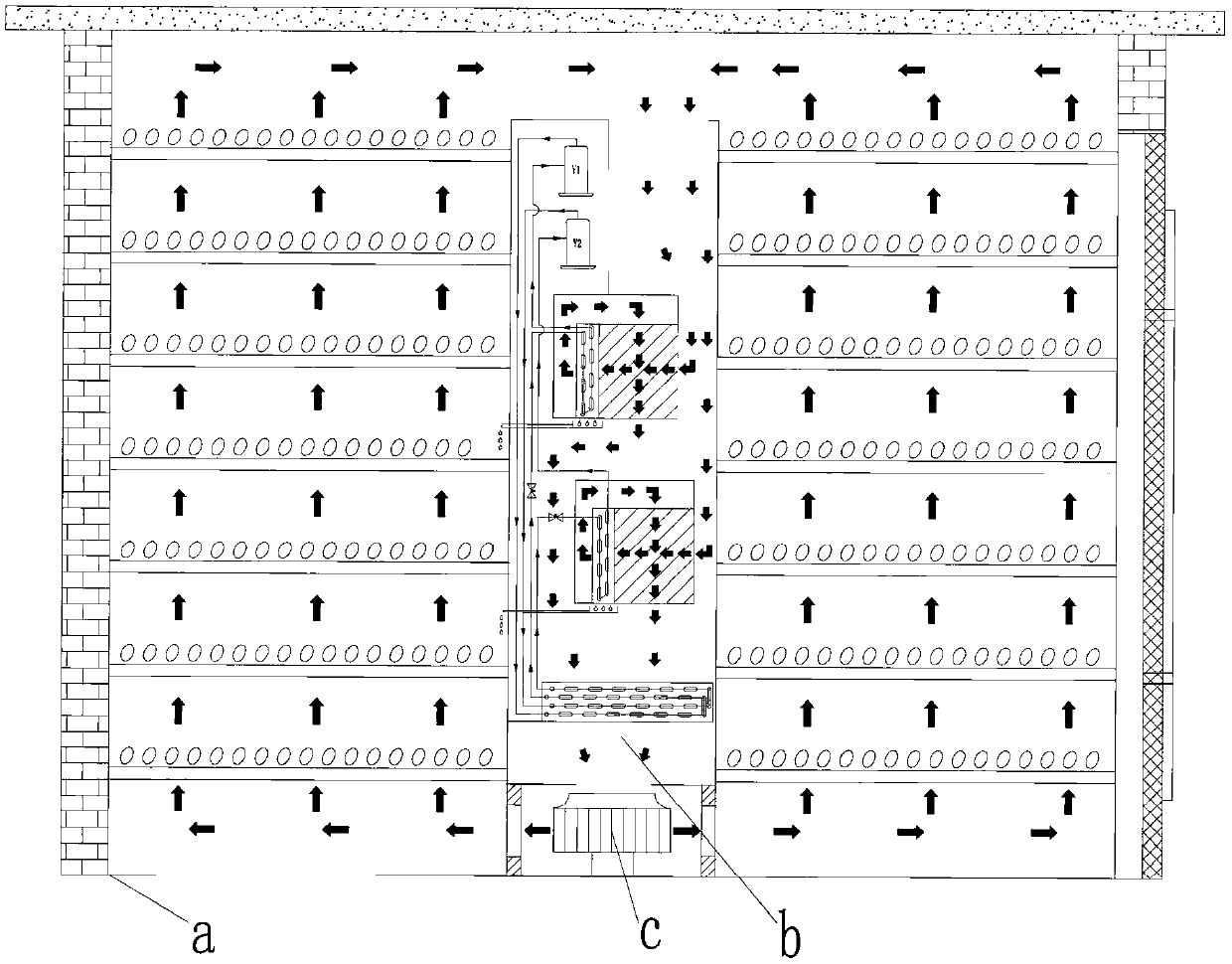

[0095] In the present embodiment, two drying houses are combined into a large drying room.

[0096] Specifically, as shown in 9-10, the drying house a1 and the drying house a2 are arranged side by side and share a partition wall d; in this embodiment, two adjacent drying houses share a heat pump drying system, The heat pump drying system includes a group of heat pump units b and a centrifugal fan c arranged at the air outlet on the top of the heat pump unit b.

[0097] In this embodiment, the heat pump unit b is arranged in the middle of the partition wall d between the drying house a1 and the drying house a2, and the high-temperature dry air generated by the heat pump drying system diffuses around and transports to the two drying houses respectively, such as image 3 shown in .

[0098] For the past ten years, nearly 1.2 million intensive tobacco-curing houses have been built nationwide in accordance with the National Tobacco Banzong (2009) No. 418 Document "Technical Specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com