Construction method for bearing overlapped heat-insulating floor slab

A construction method and thermal insulation board technology, applied in the direction of floor slabs, building structures, building components, etc., can solve the problems of complex formwork support, formwork removal, lack of thermal insulation effect, mold waste, etc., to achieve improved thermal insulation effect, good Waterproof, effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

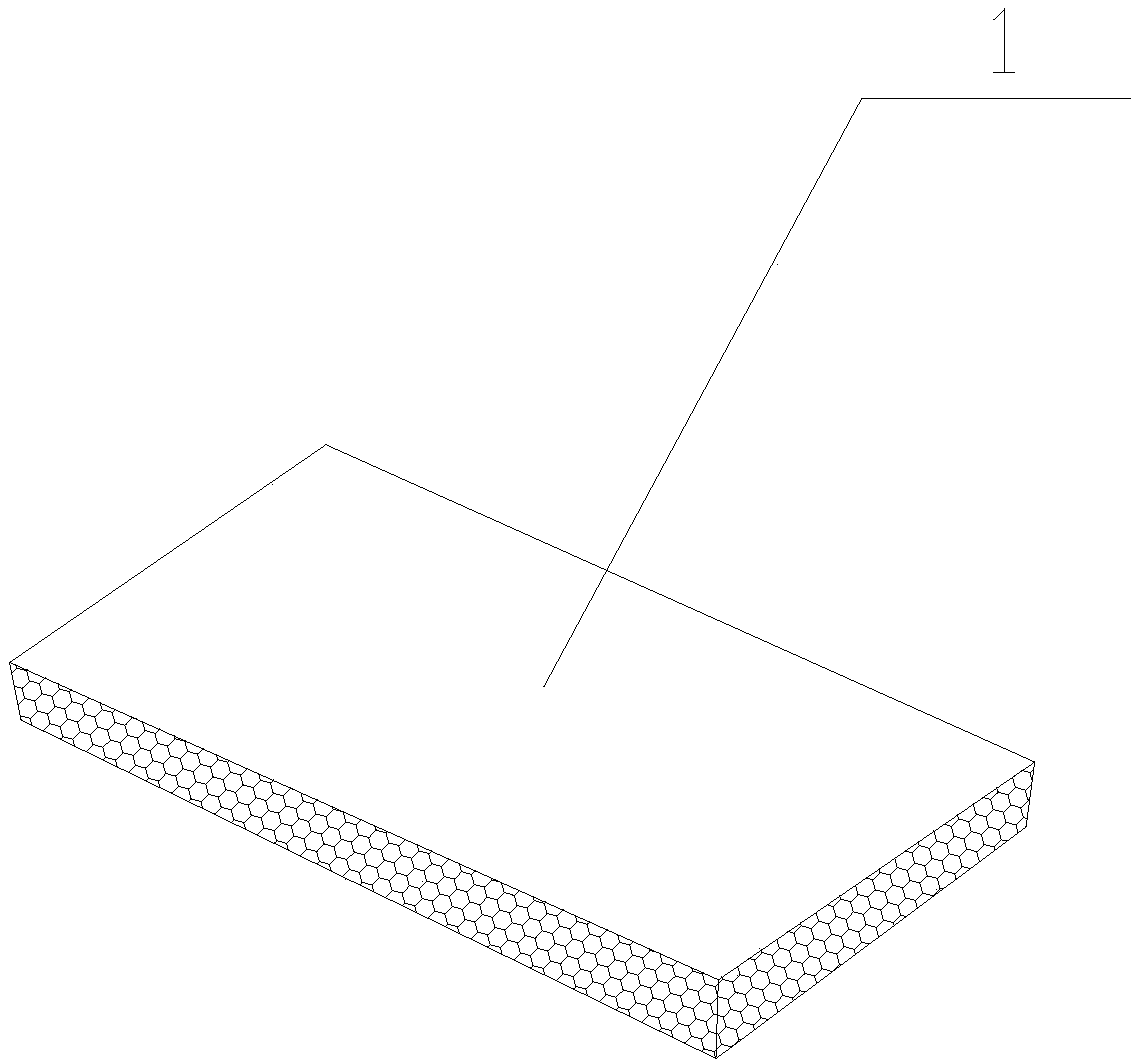

[0032] (1) Preparation of insulation board 1: The insulation board 1 includes at least an insulation layer 11, which is made of cement and aggregates. The aggregates include agricultural and forestry wastes and / or lightweight aggregates. Aggregates are mixed to make thermal insulation mortar, which is poured into a mold to form thermal insulation board 1;

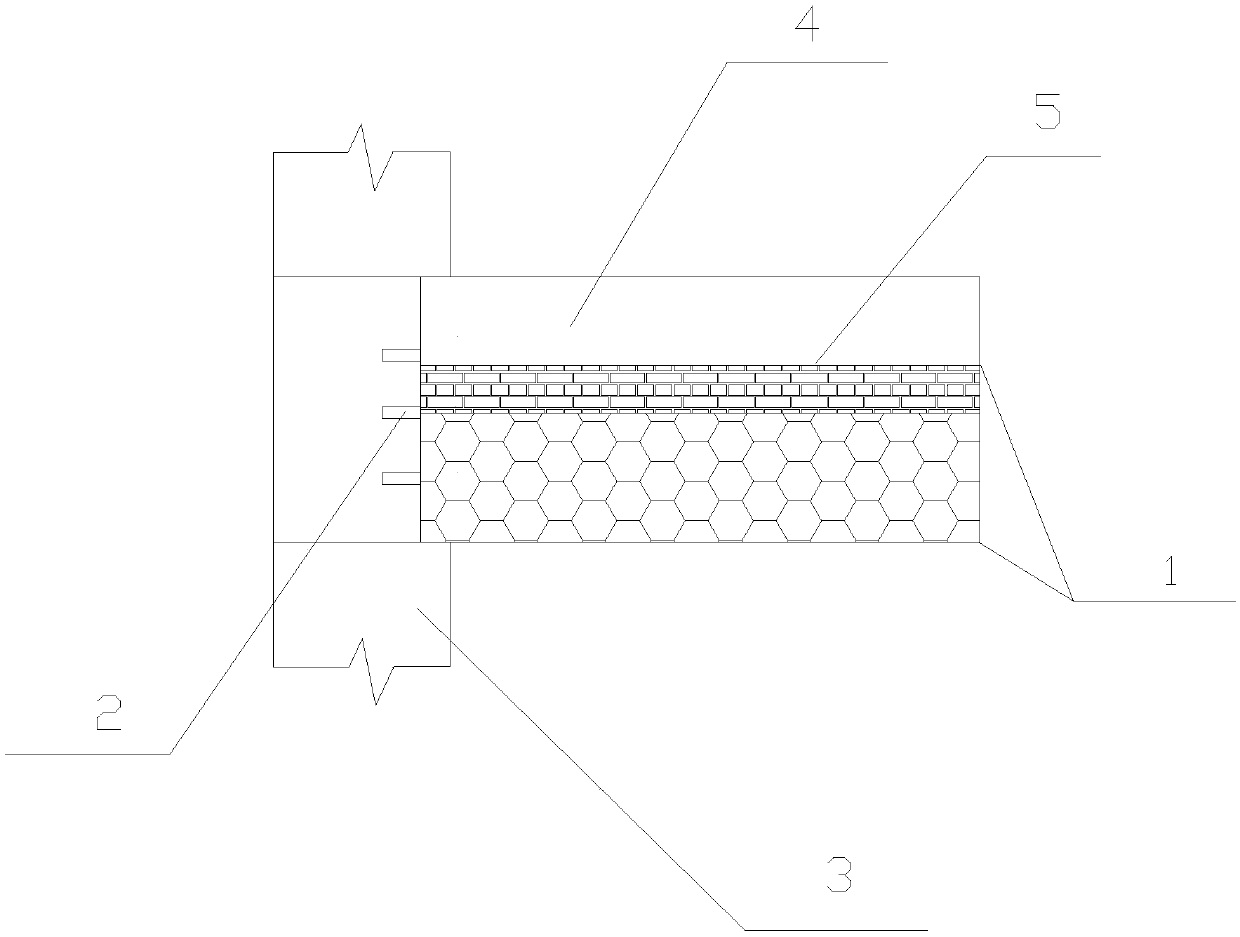

[0033] (2) Hoisting of insulation board 1: hoisting and placing the insulation board 1 formed in step (1) on the beam or wall 3, and then laying steel bars 2 on the insulation board 1;

[0034] (3) Cast-in-situ of the laminated layer: use the thermal insulation board 1 directly as a template to pour the concrete to construct the cast-in-place load-bearing floor 4, and the end of the thermal insulation board 1 is fixed integrally with the beam or wall 3 through the cast-in-place concrete. The cement slurry of the load-bearing floor 4 penetrates into the thermal insulation board 1, solidifies with the aggregates in the thermal ins...

specific Embodiment approach 1

[0045] Such as figure 1 , figure 2 As shown, an overlapped thermal insulation board 1 is mixed with cement, crop straws, and ceramsite to form a thermal insulation board 1. The thermal insulation board 1 has steel bars 2 placed in it to increase the strength of the thermal insulation board 1. The thermal insulation board 1 is placed on the beam or wall 3, and then steel bars 2 are arranged on the thermal insulation board 1, and then concrete is cast in-situ to form the cast-in-place load-bearing floor 4, and the cement slurry of the cast-in-place load-bearing floor 4 penetrates Into the thermal insulation board 1, solidify with the lightweight aggregate in the thermal insulation board 1 to form a thermal insulation solidification bonding layer 5 in the thermal insulation board 1. The thermal insulation solidification bonding layer 5 connects the thermal insulation board 11 with the The cast-in-place load-bearing floor 44 is solidified into one body to form a non-interface beari...

specific Embodiment approach 2

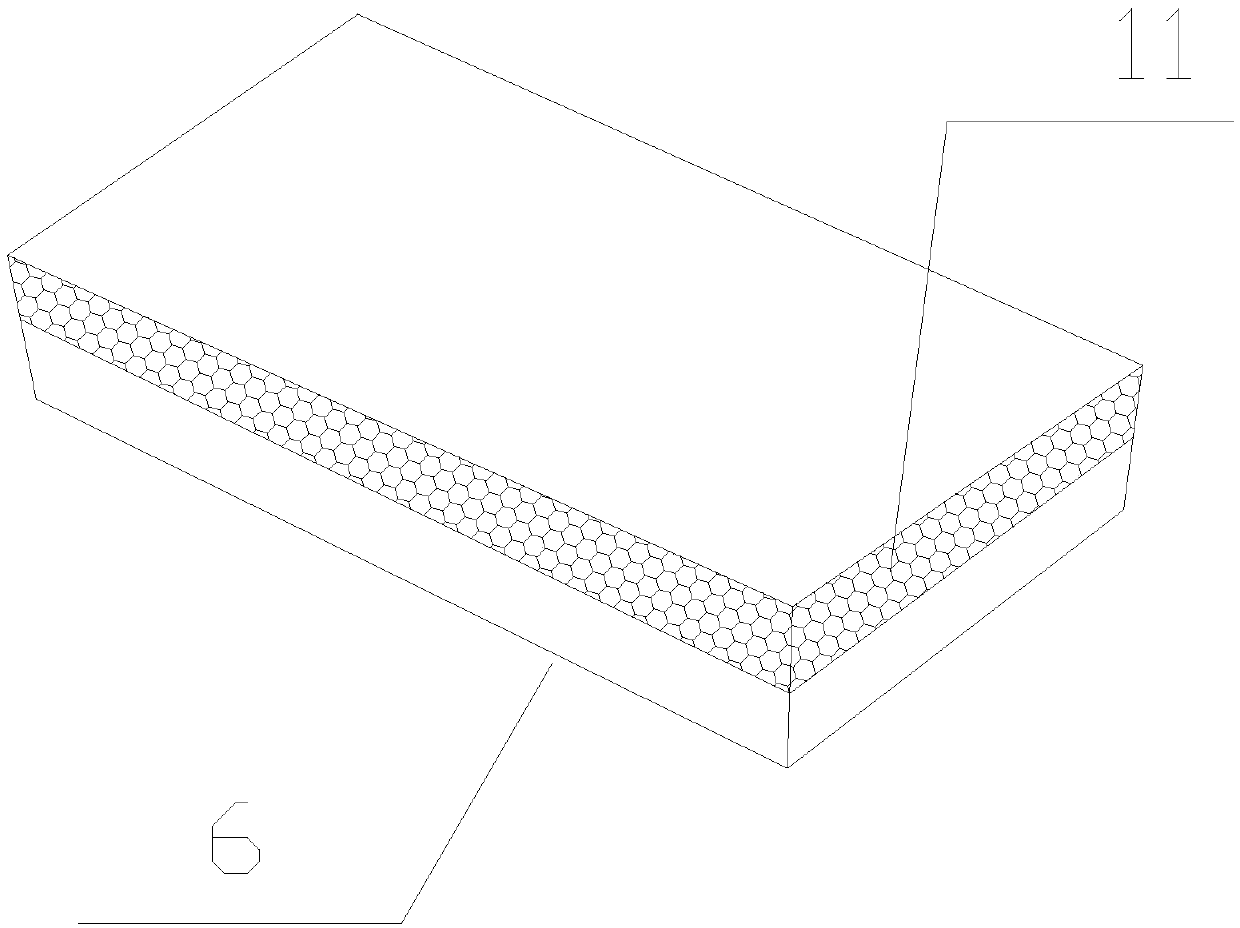

[0046] Such as image 3 , Figure 4 As shown, a kind of superimposed thermal insulation floor slab is made of concrete and steel bar 2 to make a load-bearing board 6, then mixed with cement, straw, and ceramsite, and poured on the load-bearing board 6 to form an insulation layer 11 and a load-bearing board 6. It is combined with the insulation layer 11 to form the load-bearing insulation board 1. Place the load-bearing insulation board 1 on the beam or wall 3, and then set the steel bars 2 on the load-bearing insulation board 1, and then cast concrete to make the cast-in-place The load-bearing floor 4, the cement slurry of the cast-in-place load-bearing floor 4 penetrates into the insulation layer 11 in the load-bearing insulation board 1, solidifies with the lightweight aggregate in the insulation layer 11, and forms in the insulation layer 11 The thermal insulation solidification bonding layer 5, the thermal insulation solidification bonding layer 55 solidifies the thermal ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com