Normal-temperature oxygen pressurizng device

A pressurizing device, oxygen technology, applied in the direction of oxygen preparation, oxygen/ozone/oxide/hydroxide, inorganic chemistry, etc., can solve the problem that tourists cannot carry and use it for a long time, and the vending machine does not have the function of on-site oxygen compression and other problems, to achieve the effect of low cost of use, long pressurization duration, and high precision of the filter element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

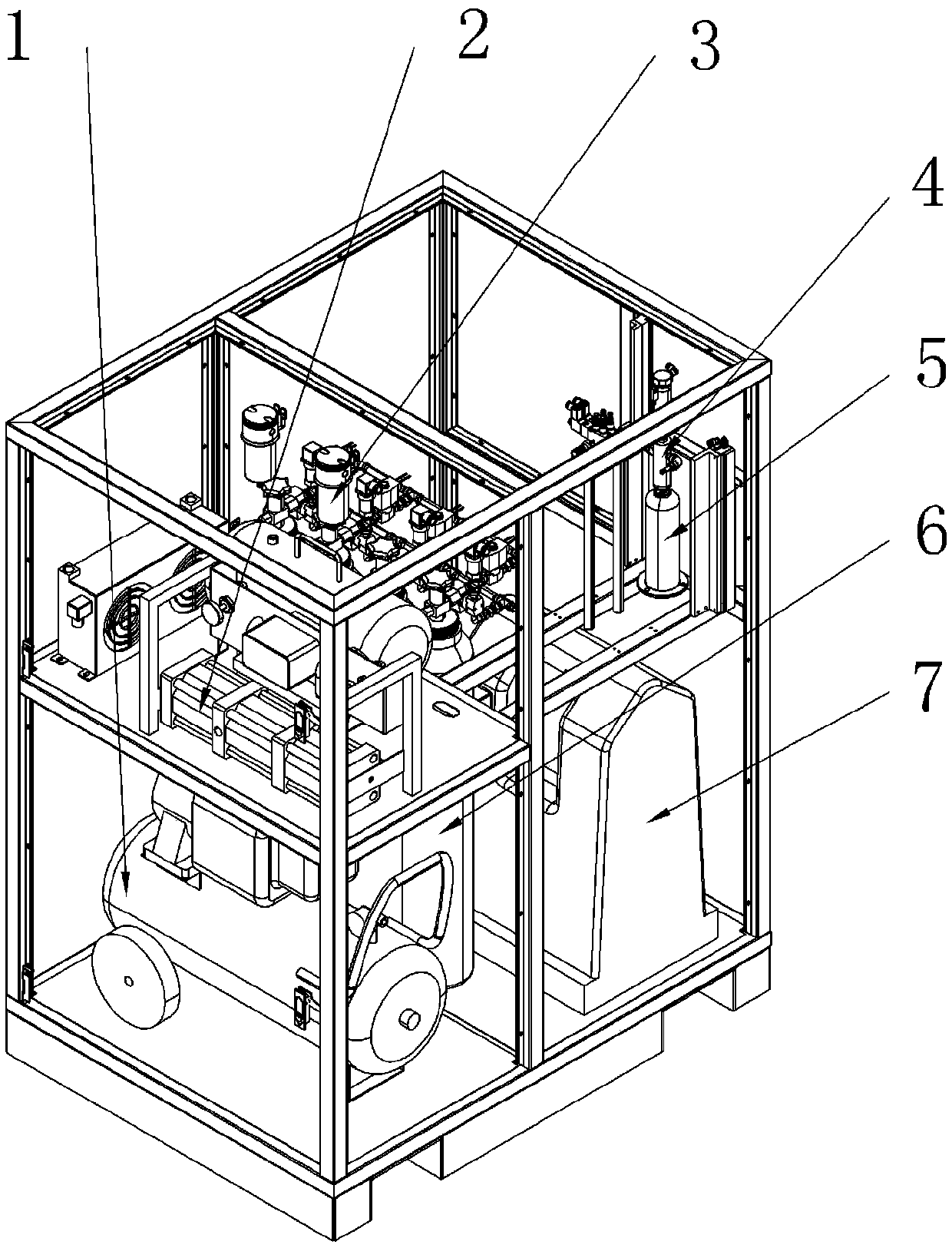

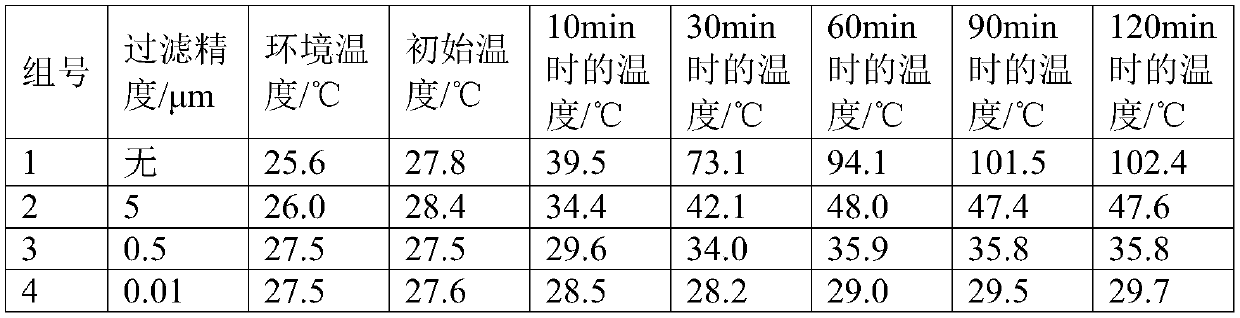

[0023] Embodiment 1: the normal temperature oxygen pressurization device in this scheme, such as figure 1 and figure 2 As shown, it includes a pneumatic supercharger 2 , an oxygen generator 7 and an air compressor 1 for providing compressed air to the oxygen generator 7 . Pneumatic supercharger 2 is the prior art, also known as pneumatic booster pump, pneumatic supercharger 2 has a driving gas input end for passing into driving gas, a gas to be compressed input and an output for passing into gas to be compressed At the output end of the compressed gas, the oxygen generator 7 is a pressure swing adsorption oxygen generator. The output end of the air compressor 1 communicates with the air source input end of the oxygen generator 7 to provide the oxygen generator 7 with the compressed air required for oxygen production. The output end of the oxygen generator 7 communicates with the input end of the gas to be compressed of the pneumatic supercharger 2 to provide the pneumatic s...

Embodiment 2

[0034] Embodiment 2: The improvement of this embodiment on the basis of Embodiment 1 is: remove the filling head 4 on the output end of the pneumatic booster 2, and the gas output end of the pneumatic booster 2 is connected with a pressure gas cylinder 6 , The pressure gas cylinder 6 is processed with an exhaust port, and a pressure reducing valve and a shut-off valve are installed on the exhaust port. The exhaust port is connected with a filling head 4 through a pipeline. The compressed gas with higher pressure produced by the pneumatic supercharger 2 enters the pressure gas storage bottle 6 for storage, and is filled into the oxygen portable bottle 5 after decompression when necessary. On the one hand, the pressure gas storage bottle 6 can store a large amount of compressed oxygen, and when necessary, oxygen is released from the pressure gas storage bottle 6 for filling, so as to avoid repeatedly starting the compressor or the pneumatic supercharger 2 according to the fillin...

Embodiment 3

[0035] Embodiment 3: In this embodiment, on the basis of Embodiment 1, the pressure gas cylinder 6 is a medical pressure cylinder. The medical pressure bottle has a high pressure safety factor, which further plays a role in safety protection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| filtration accuracy | aaaaa | aaaaa |

| filtration accuracy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com