Linear type dual-layer automatic coding steel seal coding device

An automatic coding and linear technology, which is applied in the field of steel printing and coding, can solve the problems of frequent replacement of double-layer steel printing molds, etc., achieve the effects of reducing labor intensity, solving steel printing molds, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

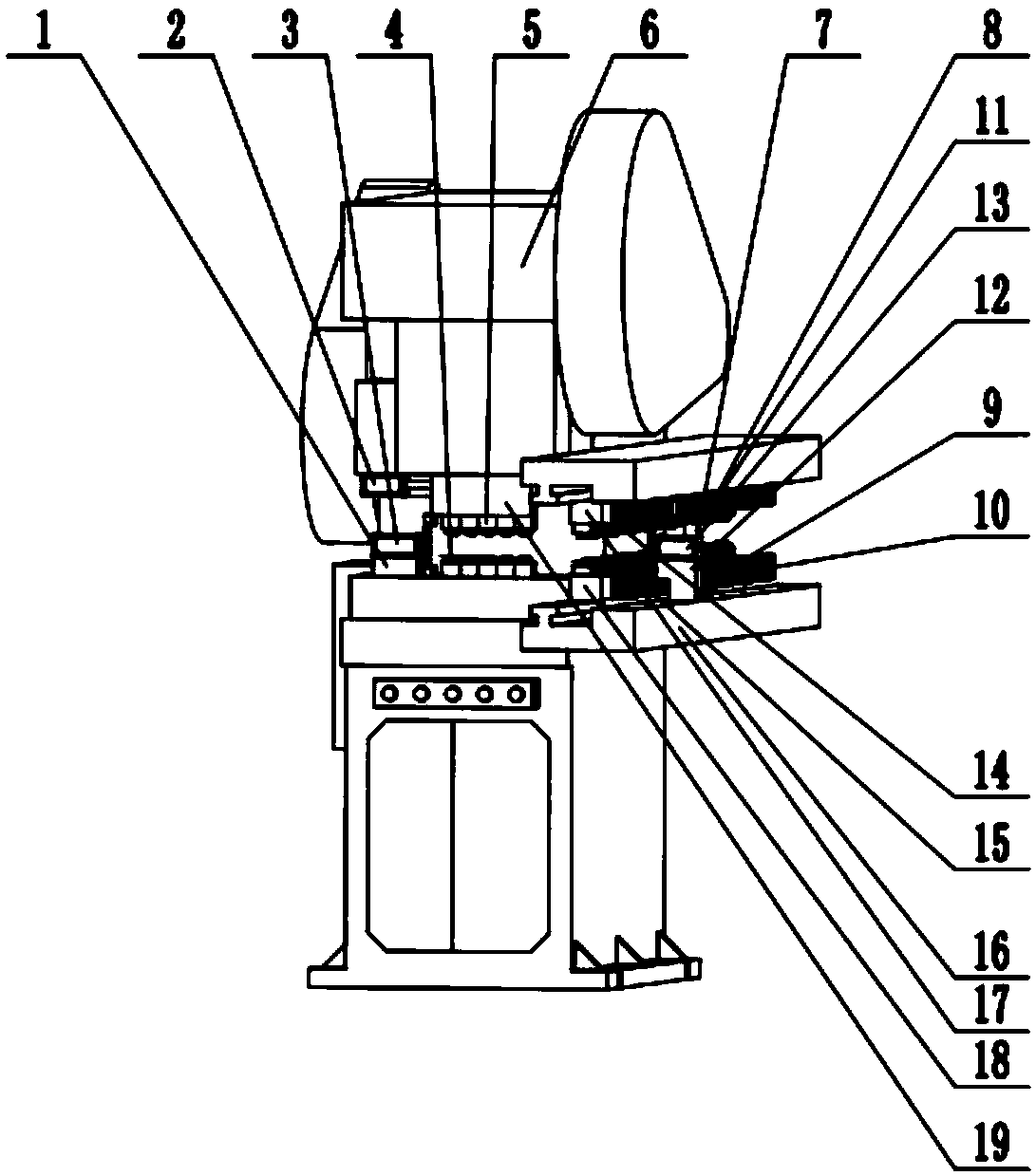

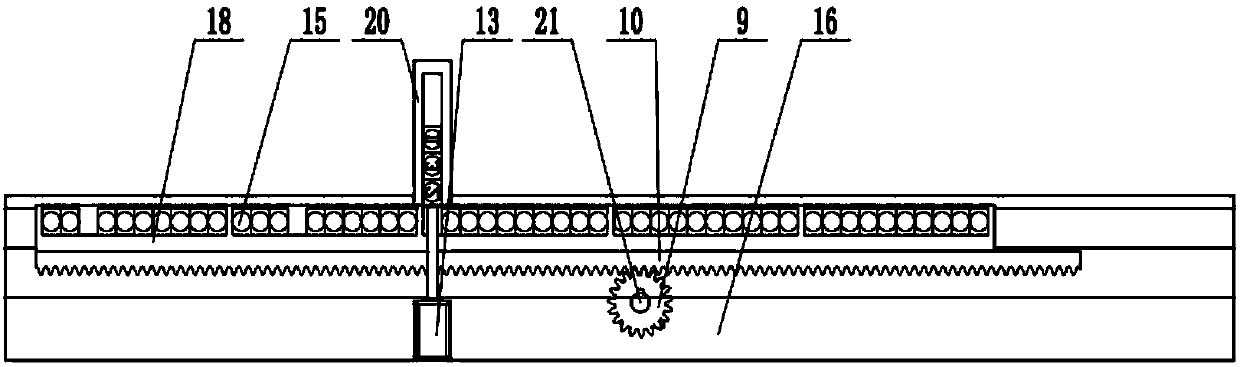

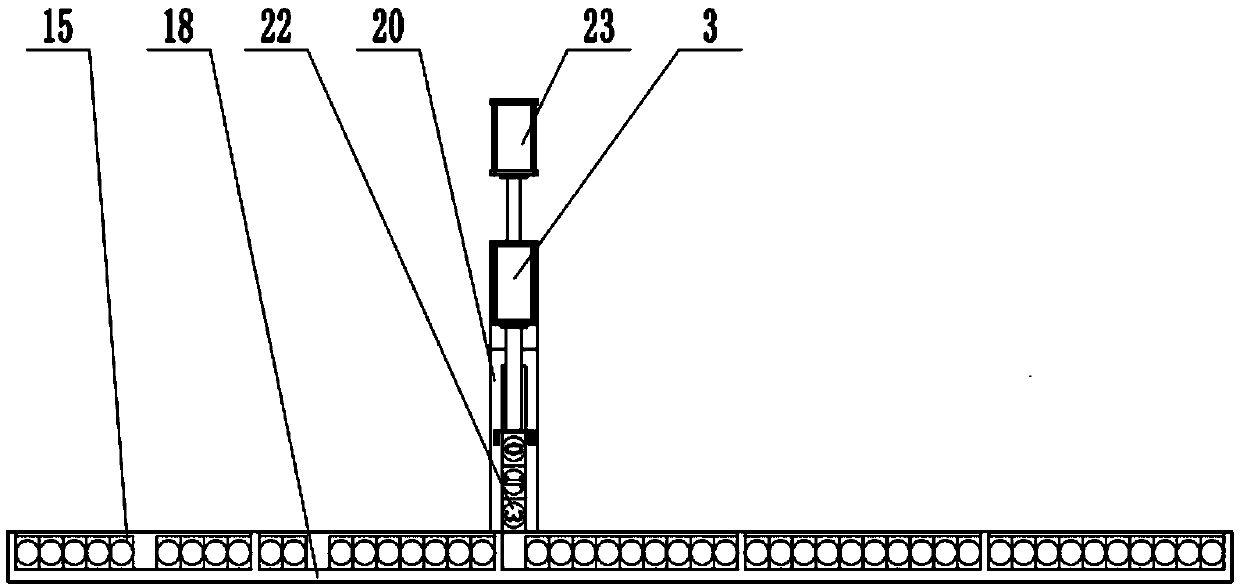

[0022] The present invention will be further described below in conjunction with accompanying drawing: first gear second gear

[0023] Such as Figure 1~4 As shown, a linear double-layer automatic coding steel stamp coding device includes a stamping machine 6, an automatic coding mechanism and an automatic code return mechanism. 11. The first gear 9, the first rack 10, the second gear 7, the second rack 8, the male stamp to be selected 15, the female stamp to be selected 14, the male mold loading groove 18, the female mold loading groove 17. Coded cylinder 13, coded cylinder mounting seat 12, working male mold box 20 and working female mold box 19, the double-layer support table 16 is fixed on one side of the stamping machine 6, and the stepping motor 21 is fixedly installed On the double-layer support platform 16, the synchronous shaft 11 is connected to the output shaft of the stepper motor 21 through a coupling, and the first gear 9 and the second gear 7 are installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com