High color rendering and wide spectrum white light LED light source

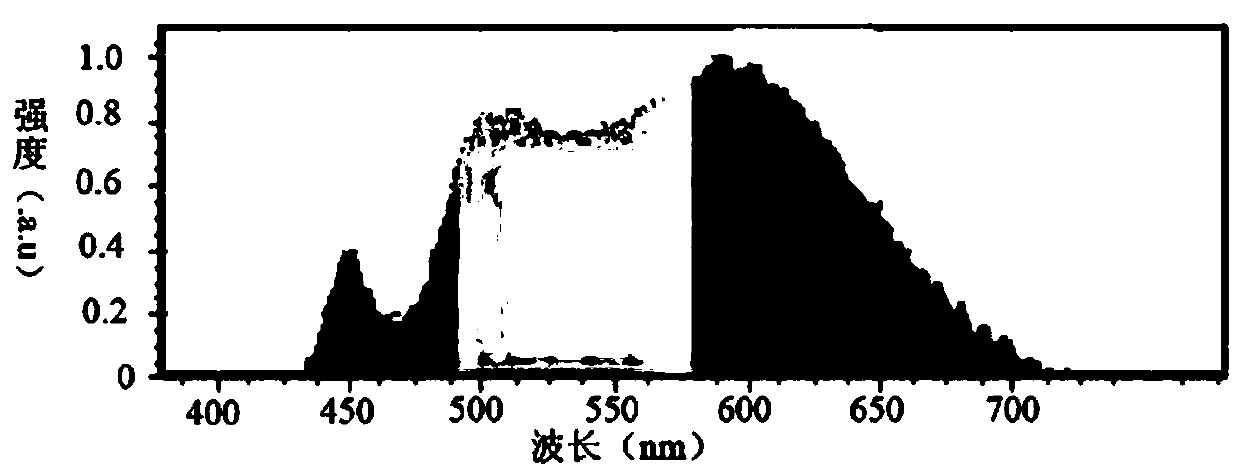

A LED light source and wide-spectrum technology, which is applied in the field of wide-spectrum white LED light source and high color rendering, can solve the problems of narrow white light source spectrum, low color rendering index, and narrow spectrum, and achieve high energy conversion efficiency and good color temperature uniformity , the effect of wide spectral range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

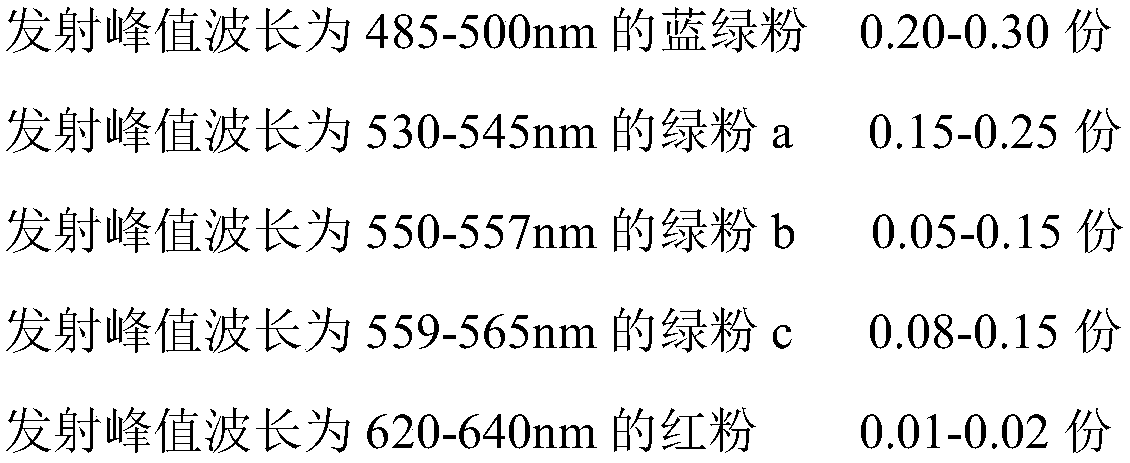

[0030] A high-color-rendering, wide-spectrum white LED light source, including a fluorescent glue and a blue light chip. The LED fluorescent glue is formed by mixing phosphor powder and silica gel. The phosphor powder includes the following components in parts by mass:

[0031]

[0032] The wavelength band of the blue light chip is 447nm.

[0033] The mass ratio of the fluorescent powder to the silica gel is 0.1:1, the silica gel is composed of silica gel A and silica gel B, and the mass ratio of silica gel A to silica gel B is 1:0.6.

[0034] A method for preparing a high-color-rendering, wide-spectrum white LED light source, comprising the following steps:

[0035] (1) Fixing the chip: Fix the blue light chip on the LED bracket with silver glue;

[0036] (2) Welding: Weld the blue light chip in step (1) with the circuit of the LED bracket with gold wire, then use glue to dam the blue light chip and set aside;

[0037] (3) Powder mixing: Weigh each component according to...

Embodiment 2

[0040] A high-color-rendering, wide-spectrum white LED light source, including a fluorescent glue and a blue light chip. The LED fluorescent glue is formed by mixing phosphor powder and silica gel. The phosphor powder includes the following components in parts by mass:

[0041]

[0042] The wavelength band of the blue light chip is 452nm.

[0043] The mass ratio of the fluorescent powder to the silica gel is 0.3:1, the silica gel is composed of silica gel A and silica gel B, and the mass ratio of silica gel A to silica gel B is 1:0.9.

[0044] A method for preparing a high-color-rendering, wide-spectrum white LED light source, comprising the following steps:

[0045] (1) Fixing the chip: Fix the blue light chip on the LED bracket with silver glue;

[0046] (2) Welding: Weld the blue light chip in step (1) with the circuit of the LED bracket with a gold wire, clean and reserve;

[0047] (3) Powder mixing: Weigh each component according to the formula, stir and mix the fluo...

Embodiment 3

[0050] A high-color-rendering, wide-spectrum white LED light source, including a fluorescent glue and a blue light chip. The LED fluorescent glue is formed by mixing phosphor powder and silica gel. The phosphor powder includes the following components in parts by mass:

[0051]

[0052]

[0053] The wavelength range of the blue light chip is 452nm.

[0054] The mass ratio of the fluorescent powder to the silica gel is 0.38:1, the silica gel is composed of silica gel A and silica gel B, and the mass ratio of silica gel A to silica gel B is 1:1.

[0055]A method for preparing a high-color-rendering, wide-spectrum white LED light source, comprising the following steps:

[0056] (1) Fixing the chip: Fix the blue light chip on the LED bracket with silver glue;

[0057] (2) Welding: Weld the blue light chip in step (1) with the circuit of the LED bracket with a gold wire, clean and reserve;

[0058] (3) Powder mixing: weigh each component according to the formula, stir and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com