Modeling method for quickly simulating bolt connection of a single-sided lap joint piece

A modeling method and bridge joint technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low calculation efficiency and complicated process, so as to improve calculation efficiency, meet engineering needs, and shorten calculation time. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

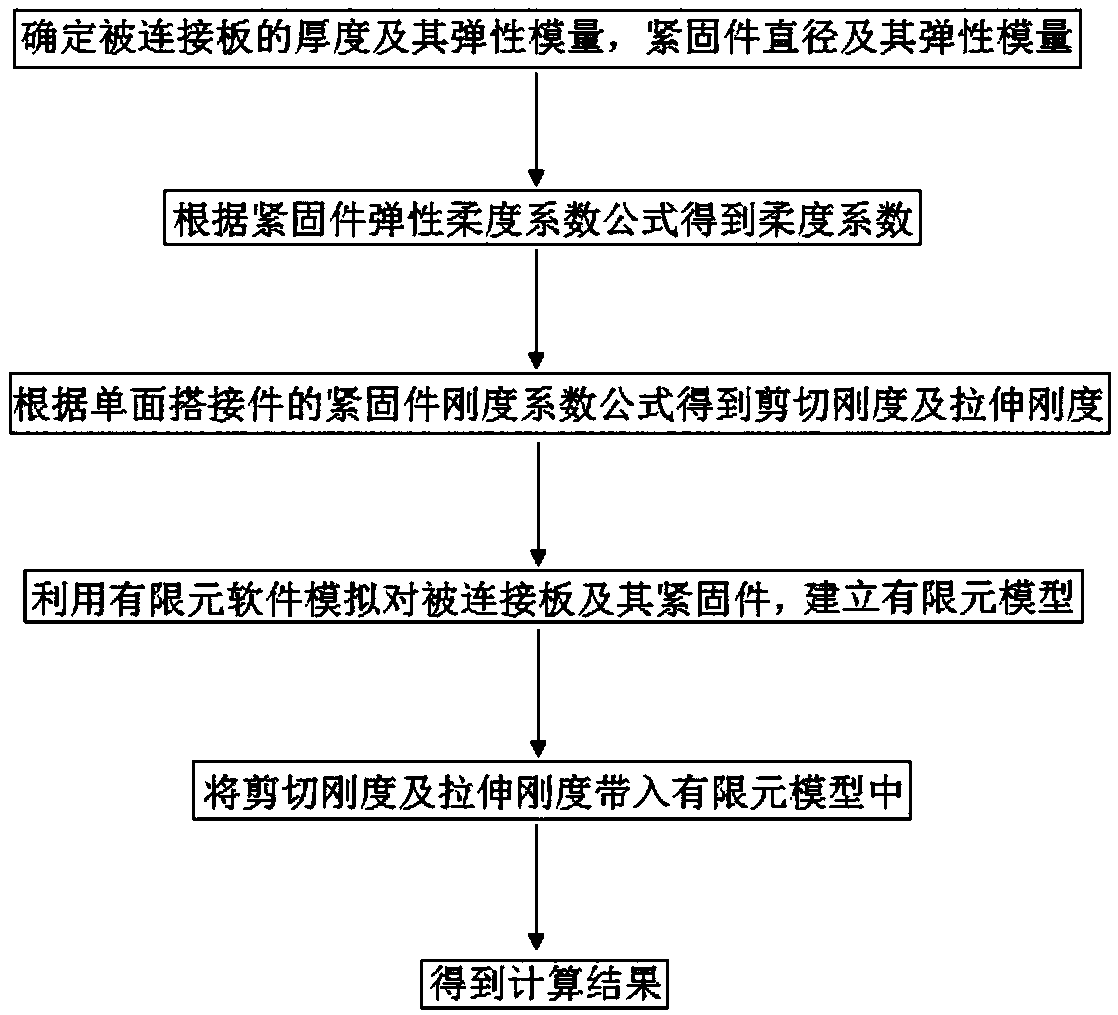

[0030] The steps of the finite element modeling method for quickly simulating bolted connections of the present invention are as follows:

[0031] 1) First determine the thickness of the board to be connected (thickness of the upper board t 1 3mm, lower plate thickness t 2 is 4mm), material properties (E is 71000MPa) and the fasteners used are titanium bolts, diameter (d is 6mm), material properties (E 1 is 109000MPa),;

[0032] 2) Determine the fastener compliance coefficient of the single-sided lap joint;

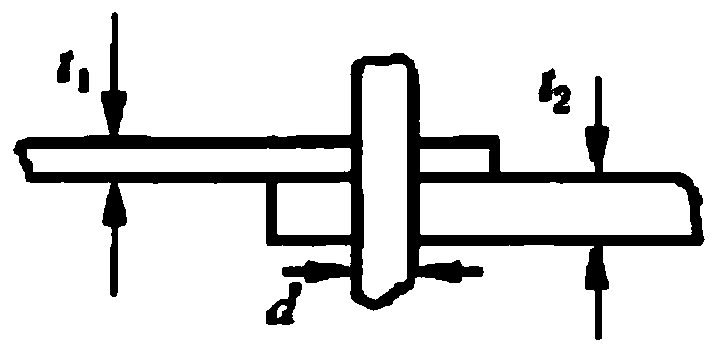

[0033] for figure 2 For the simple shear connector shown, the elastic compliance coefficient C of the fastener can be determined by the following formula:

[0034]

[0035] In the formula: d—the diameter of the fastener;

[0036] t 1 — the thickness of the thinner plate;

[0037] t 2 — the thickness of the thicker plate;

[0038] E—Elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com