Optical filter and preparation method thereof, fingerprint recognition module and electronic device

A technology of filter and long-wave-pass film system, applied in filter, character and pattern recognition, optics, etc., can solve the problem of unable to meet the requirements of fingerprint sensor module use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

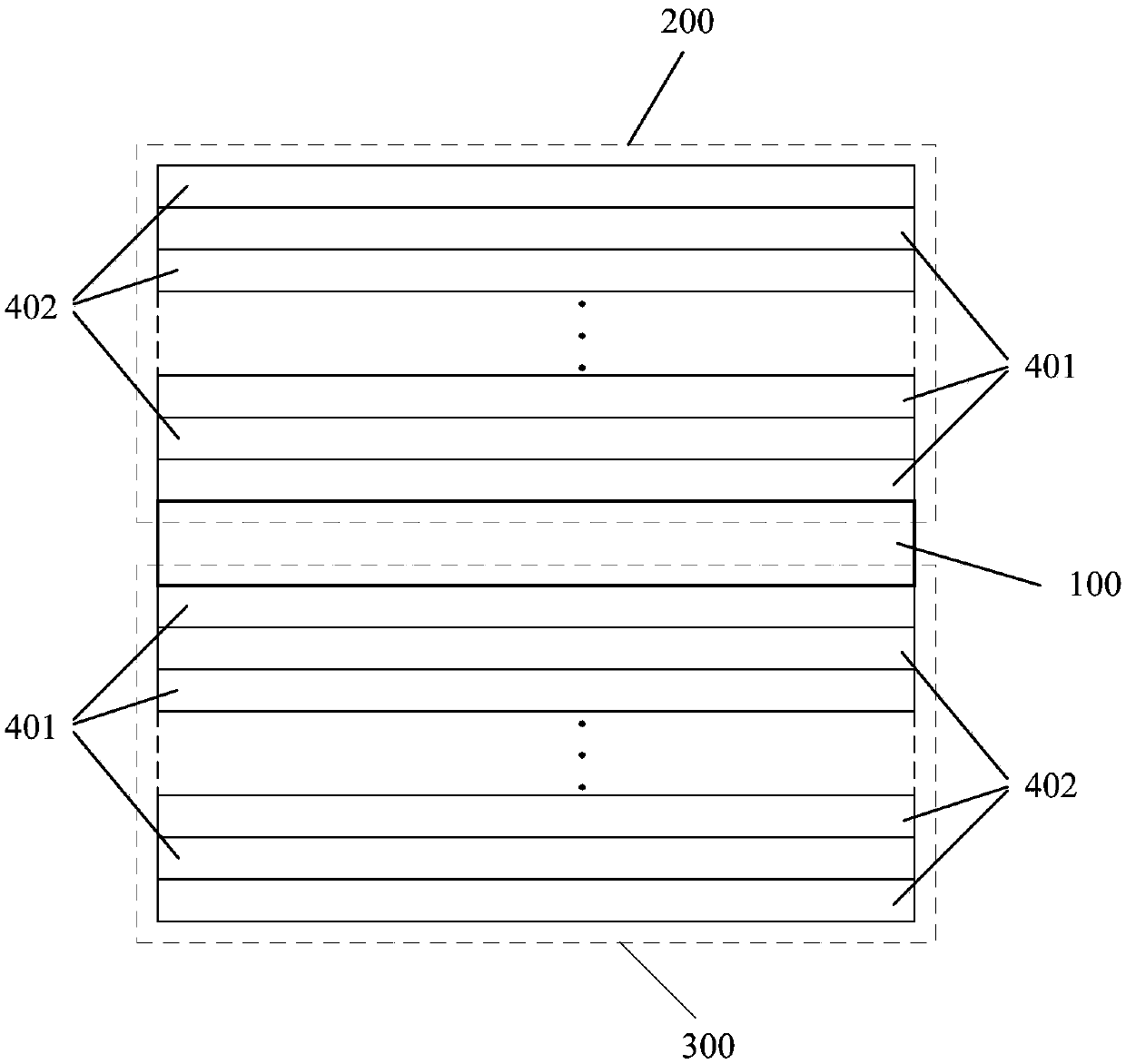

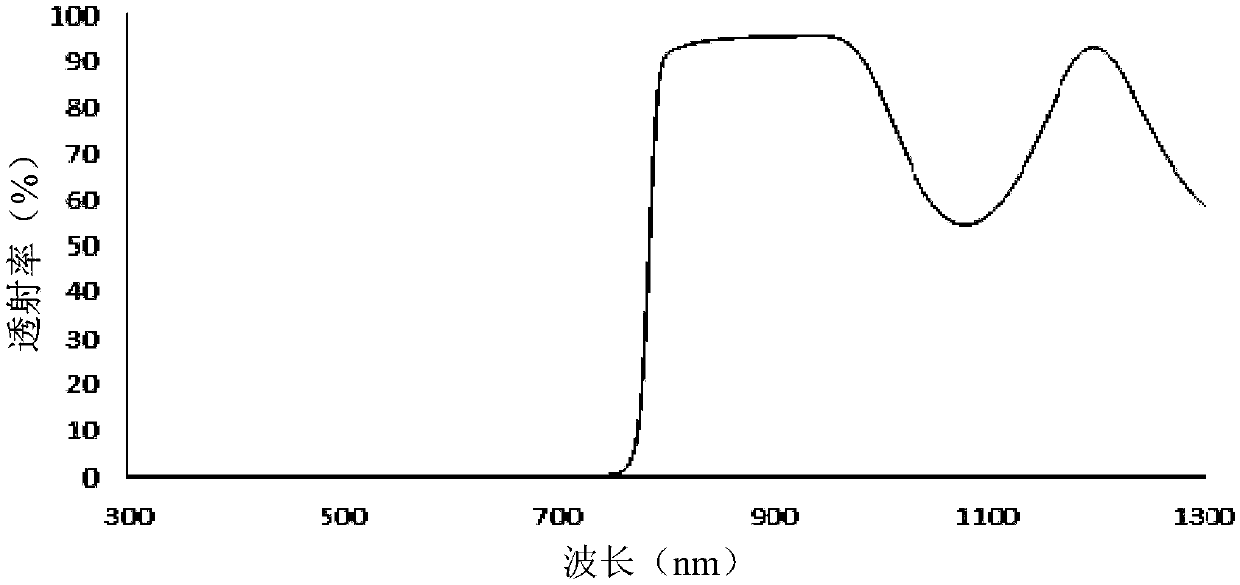

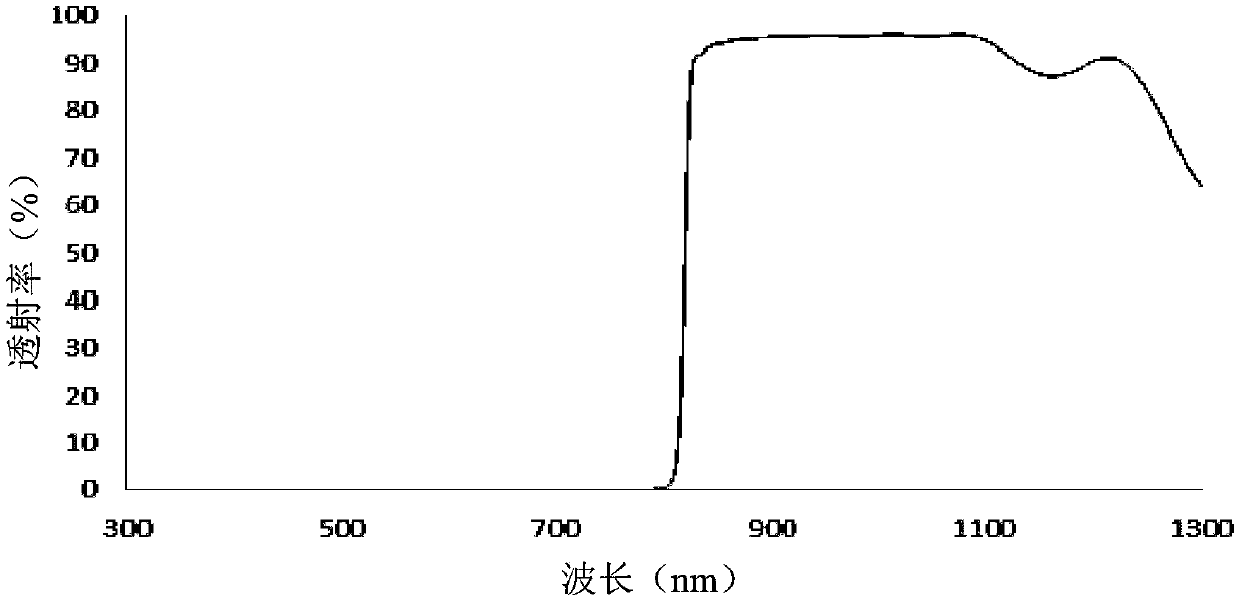

[0043] An embodiment of the present invention provides an optical filter, the optical filter is a near-infrared optical filter through 830-950nm. figure 1 A structural schematic diagram of an optical filter provided for an embodiment of the present invention, such as figure 1 As shown, the filter includes a transparent substrate 100 and a first long-wave pass film system 200 and a second long-wave pass film system 300 respectively arranged on both sides of the transparent substrate 100; the first long-wave pass film system 200 and the second long-wave pass film system All systems 300 include alternately stacked high-refractive-index film layers 401 and low-refractive-index film layers 402; the film system structure of the first long-wave pass film system 200 includes (0.5HL0.5H)^10, and the The central wavelength of the transition zone is 700-900nm; the film structure of the second long-wave pass film system 300 includes (0.5HL0.5H)^14, and the transition zone center wavelengt...

Embodiment 2

[0068] The embodiment of the present invention also provides a method for preparing an optical filter, which can be completed in a vacuum sputtering coating machine, and the optical filter as in the first embodiment above can be prepared by this method. The method includes:

[0069] forming a first long-wave pass film system and a second long-wave pass film system respectively on both sides of the transparent substrate to obtain an optical filter;

[0070] Wherein, the first long-wave pass film system and the second long-wave pass film system both include alternately stacked high-refractive index film layers and low-refractive index film layers; the film structure of the first long-wave pass film system includes (0.5HL0.5H)^ 10. The central wavelength of the transition zone of the first long-wave pass film system is 700-900nm; the film structure of the second long-wave pass film system includes (0.5HL0.5H)^14, and the transition zone center wavelength of the second long-wave p...

Embodiment 3

[0090] The embodiment of the present invention also provides a fingerprint identification module, which includes the optical filter of the first embodiment above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com