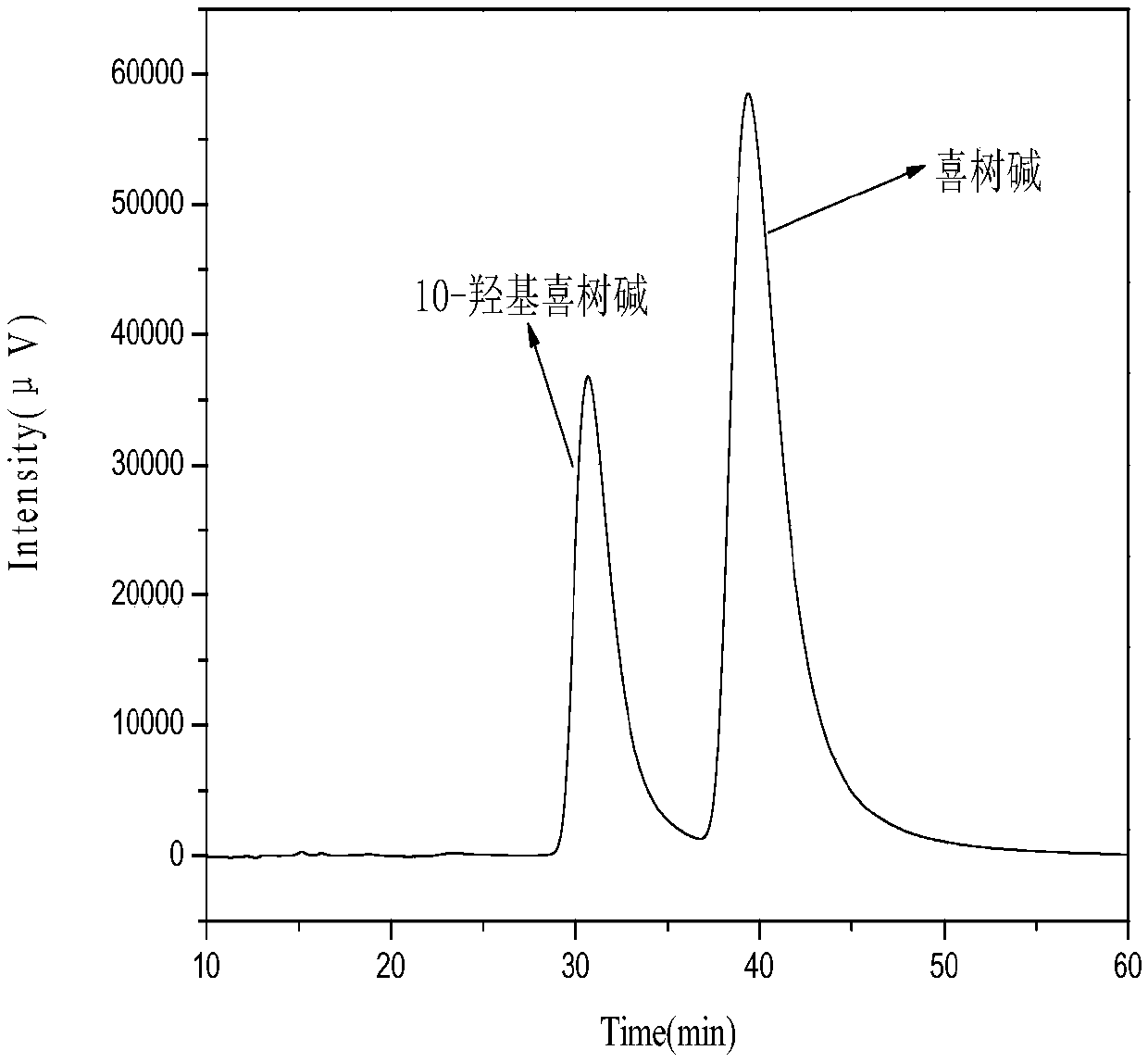

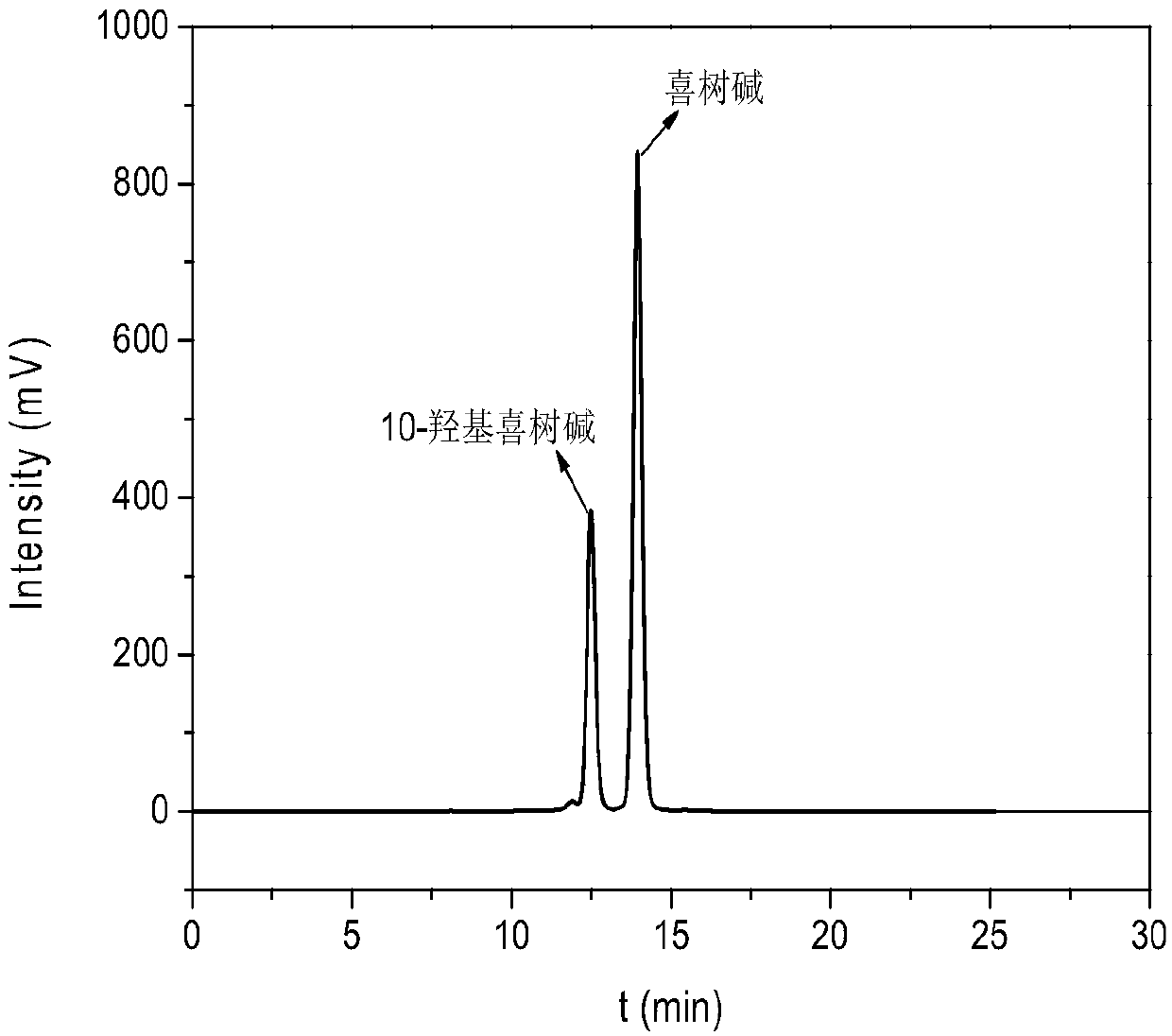

Method for efficient separation of camptothecin and 10-hydroxycamptothecin by core-shell SiO2@rosin-based polymer chromatographic column

A hydroxycamptothecin, core-shell type technology is applied in the field of high performance liquid chromatography, and can solve the problems of cumbersome preparation process of stationary phase fillers, low separation between 10-hydroxycamptothecin and camptothecin, and rosin-based polymer chromatography. The problem of low number of theoretical plates in the column can achieve the effect of good separation performance, rich pore structure and rich surface functional groups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0044] 2.0g of methacrylic acid, 2.0g of maleopimaric acid ethylene glycol acrylate and 0.2g of azobisisobutyronitrile were fully mixed, evenly coated on the surface of 400g of silica gel, and then placed in 1000mL of 1% mass fraction of ten Carry out free radical polymerization reaction in aqueous solution of dialkyl sodium sulfate for 8 hours, then perform Soxhlet extraction of the product with absolute ethanol, and then vacuum-dry to obtain core-shell SiO 2 @ Rosin-based polymer microspheres.

[0045] After detection and analysis, the core-shell type SiO obtained in this embodiment 2 The particle size distribution of @rosin-based polymer microspheres is concentrated in the range of 2-10μm, the average pore size is 0.50nm, and the specific surface area is 350m 2 / g.

preparation Embodiment 2

[0047] After fully mixing 7.5g of methacrylic acid, 1.5g of propylene pimaric acid ethylene glycol acrylate and 2.25g of azobisisoheptanonitrile, they are evenly coated on the surface of 225g of silica gel, and then placed in 100mL of 5% dodecyl The free radical polymerization reaction was carried out in an aqueous solution of sodium alkyl sulfate for 9 hours, and then the product was subjected to Soxhlet extraction with absolute ethanol, and then vacuum-dried to obtain the core-shell SiO 2 @ Rosin-based polymer microspheres.

[0048] After detection and analysis, the core-shell type SiO obtained in this embodiment 2 The particle size distribution of @rosin-based polymer microspheres is concentrated around 12-18μm, the average pore size is 3.79nm, and the specific surface area is 247m 2 / g.

preparation Embodiment 3

[0050] After fully mixing 0.5g methyl methacrylate, 10g maleopimaric acid ethylene glycol acrylate and 14mg dibenzoyl peroxide, evenly apply it to the surface of 10.5g silica gel, and then place it in 100mL of 15% mass fraction Carry out free radical polymerization reaction in aqueous solution of sodium lauryl sulfate for 10 h, then perform Soxhlet extraction of the product with absolute ethanol, and then vacuum dry to obtain core-shell SiO 2 @ Rosin-based polymer microspheres.

[0051] After detection and analysis, the core-shell type SiO obtained in this embodiment 2 The particle size distribution of @rosin-based polymer microspheres is concentrated around 25-30μm, with an average pore size of 6.01nm and a specific surface area of 312m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com