A kind of synthetic method of 4-bromo-6-chloronicotinaldehyde

A synthesis method and chloronicotinic aldehyde technology, applied in the direction of organic chemistry and the like, can solve problems such as poor economic benefit and environmental impact, long process steps, complicated operation, etc., and achieve environmental friendliness, simplified reaction process and post-treatment. Process, the effect of optimizing reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

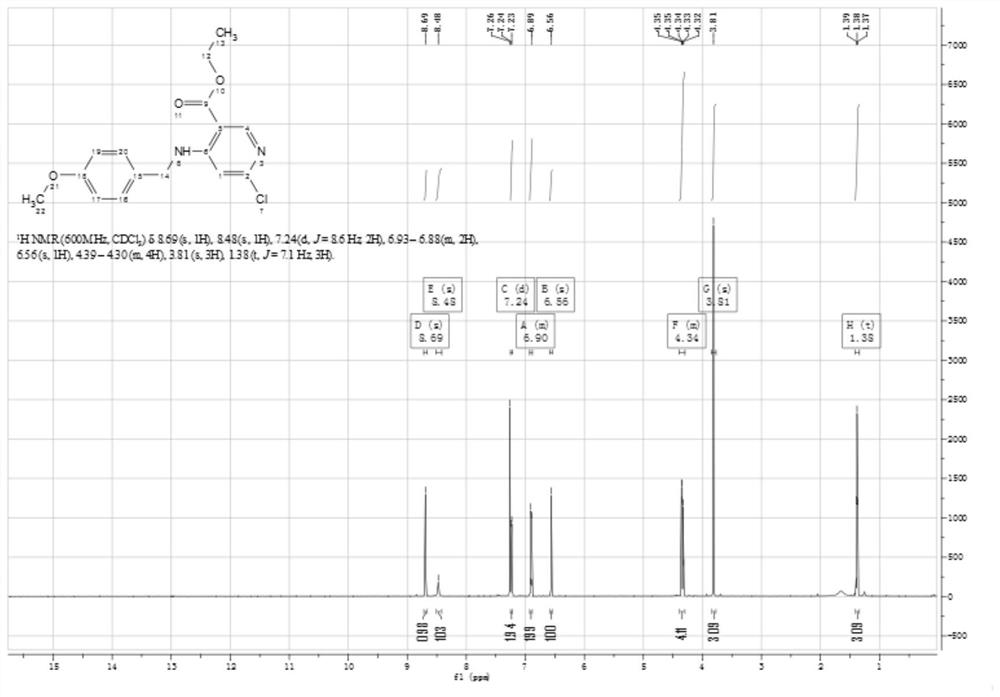

[0042] Synthesis of the first step compound (1) 6-chloro-4-((4-methoxybenzyl) amino) nicotinic acid ethyl ester:

[0043] Add 150g of ethyl 4,6-dichloronicotinate (0.68mol) and 93.5g of 4-methoxybenzylamine (0.68mol) into a 3000ml dry three-neck flask, stir mechanically, heat to 40°C, and stir overnight After the reaction was detected by thin-layer chromatography (TLC), it was added to ice water, extracted 3 times with ethyl acetate, backwashed once with saturated brine, dried by adding anhydrous sodium sulfate, and eluted from the column layer [eluent : (petroleum ether: ethyl acetate = 40: 1)] to obtain 196 g of compound (1) 6-chloro-4-((4-methoxybenzyl) amino) nicotinic acid ethyl ester, the yield was 90%.

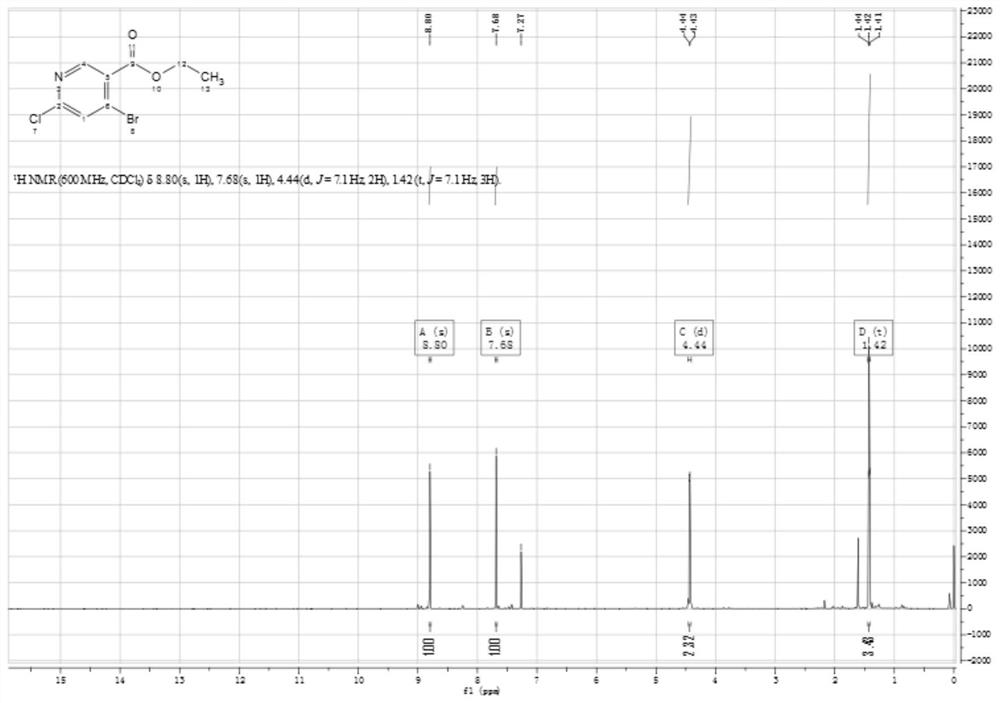

[0044] Synthesis of the second step compound (2) 4-amino-6-chloronicotinic acid ethyl ester:

[0045] Add 196g of compound (1) 6-chloro-4-((4-methoxybenzyl)amino)nicotinic acid ethyl ester (0.61mol) into 1500ml of trifluoroacetic acid (20mol) and heat at 50°C to 60°C ...

Embodiment 2

[0053] Synthesis of the first step compound (1) 6-chloro-4-((4-methoxybenzyl) amino) nicotinic acid ethyl ester:

[0054] Add 150g of ethyl 4,6-dichloronicotinate (0.68mol) and 93.5g of 4-methoxybenzylamine (0.68mol) into a 3000ml dry three-necked flask, stir mechanically, and react with stirring overnight at room temperature. As detected by TLC, the raw materials were not completely reacted, added to ice water, extracted three times with ethyl acetate, backwashed once with saturated brine, dried by adding anhydrous sodium sulfate, and eluted by column [eluent: (petroleum ether: Ethyl acetate=40:1)] to obtain 120 g of compound (1) ethyl 6-chloro-4-((4-methoxybenzyl)amino)nicotinate, with a yield of 55%.

[0055] Synthesis of the second step compound (2) 4-amino-6-chloronicotinic acid ethyl ester:

[0056] Add 120 g of compound (1) 6-chloro-4-((4-methoxybenzyl) amino) nicotinic acid ethyl ester (0.37 mol) into 600 ml of trifluoroacetic acid (8.07 mol), heat at 50 ° C to 60 Re...

Embodiment 3

[0064] Synthesis of the first step compound (1) 6-chloro-4-((4-methoxybenzyl) amino) nicotinic acid ethyl ester:

[0065] Add 150g of ethyl 4,6-dichloronicotinate (0.68mol) and 187g of 4-methoxybenzylamine (1.36mol) into a 3000ml dry three-necked flask, stir mechanically, heat to the reaction temperature of 60°C, and stir the reaction Overnight, TLC detection, the reaction was complete, added to ice water, extracted 3 times with ethyl acetate, backwashed once with saturated saline, added anhydrous sodium sulfate to dry, column eluted [eluent: (petroleum ether: Ethyl acetate=40:1)] to obtain 109 g of compound (1) ethyl 6-chloro-4-((4-methoxybenzyl)amino)nicotinate, with a yield of 50%.

[0066] Synthesis of the second step compound (2) 4-amino-6-chloronicotinic acid ethyl ester:

[0067] Add 109 g of compound (1) 6-chloro-4-((4-methoxybenzyl) amino) nicotinic acid ethyl ester (0.34 mol) into 1010 ml of trifluoroacetic acid (13.59 mol), and heat at 50° C. to 60 React overnight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com