Graphene composite material, graphene aluminum oxide composite material and preparation method and application of graphene aluminum oxide composite powder material

A kind of aluminum oxide and composite material technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of easy agglomeration, poor dispersion, limited use, etc., and achieve the effect of easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

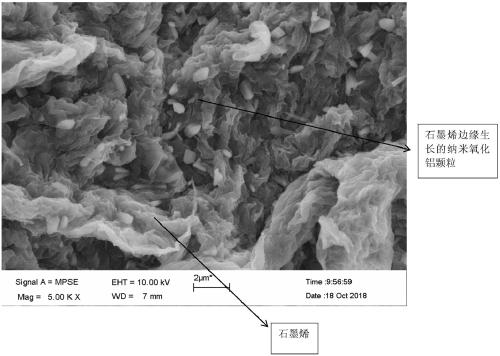

Image

Examples

preparation example Construction

[0028] A method for preparing a graphene composite material provided in an embodiment of the present application includes the following steps: slowly releasing aluminum ions from a metal salt complex in an alkaline environment, and then adding a graphene oxide material. Thereby, the problem of agglomeration of the graphene oxide material can be avoided.

[0029] Further, the preparation method of a graphene-alumina composite material provided in the embodiment of the present application includes the following steps: adding the graphene oxide material after the aluminum salt complex slowly releases aluminum ions in an alkaline environment.

[0030] By placing the aluminum salt complex in an alkaline environment, the aluminum ions originally fixed in the complex can be slowly released. Therefore, it provides a favorable guarantee for the subsequent preparation of graphene composite materials with good performance.

[0031] The inventors have found in long-term research that gra...

Embodiment 1

[0077] A kind of graphene-alumina composite powder material provided in this embodiment is prepared according to the following steps:

[0078] 1) Using sodium citrate and aluminum sulfate salt solution for electrovalent complexation, wherein the concentration of aluminum sulfate solution is 0.1mol / L;

[0079] 2) Weigh urea and graphene oxide, wherein, calculate the quality of graphene oxide according to graphene quality being 0.3% of alumina quality; After adding urea and graphene oxide to deionized water and mixing uniformly, add to step 1) In the prepared mixed solution, ensure that urea and Al 3+ The molar ratio is 2:1.

[0080] 3) Stir and heat the mixed solution prepared in step 2) in an oil bath, the stirring rate is 500r / min, the temperature is 60°C, and the reaction time is 8 hours.

[0081] 4) Centrifuge the precipitate obtained from the reaction in step 3), and dry it at 80° C. into powder.

[0082] 5) Calcining the powder obtained in step 4) at 450° C. for 30 min...

Embodiment 2

[0084] A kind of graphene-alumina composite powder material provided in this embodiment is prepared according to the following steps:

[0085] 1) Equivalent complexation of sodium citrate and aluminum sulfate solution, wherein the concentration of aluminum sulfate solution is 0.6mol / L;

[0086] 2) Weigh urea and graphene oxide, wherein, calculate the quality of graphene oxide according to graphene quality being 0.3% of alumina quality; After adding urea and graphene oxide to deionized water and mixing uniformly, add to step 1) In the prepared mixed solution, ensure that urea and Al 3+ The molar ratio is 3:1.

[0087] 3) Stir and heat the mixed solution prepared in step 2) in an oil bath, the stirring rate is 500r / min, the temperature is 100°C, and the reaction time is 12 hours.

[0088] 4) Centrifuge the precipitate obtained from the reaction in step 3), and dry it at 100° C. into powder.

[0089] 5) Calcining the powder obtained in step 4) at 440° C. under a nitrogen atmos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com