Parameter design method of tire cavity resonance noise attenuation device

A resonance noise and parameter design technology, which is applied to tire parts, calculation, transportation and packaging, etc., can solve problems such as increasing fuel consumption and cost, failing to achieve noise reduction, and affecting wheel weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

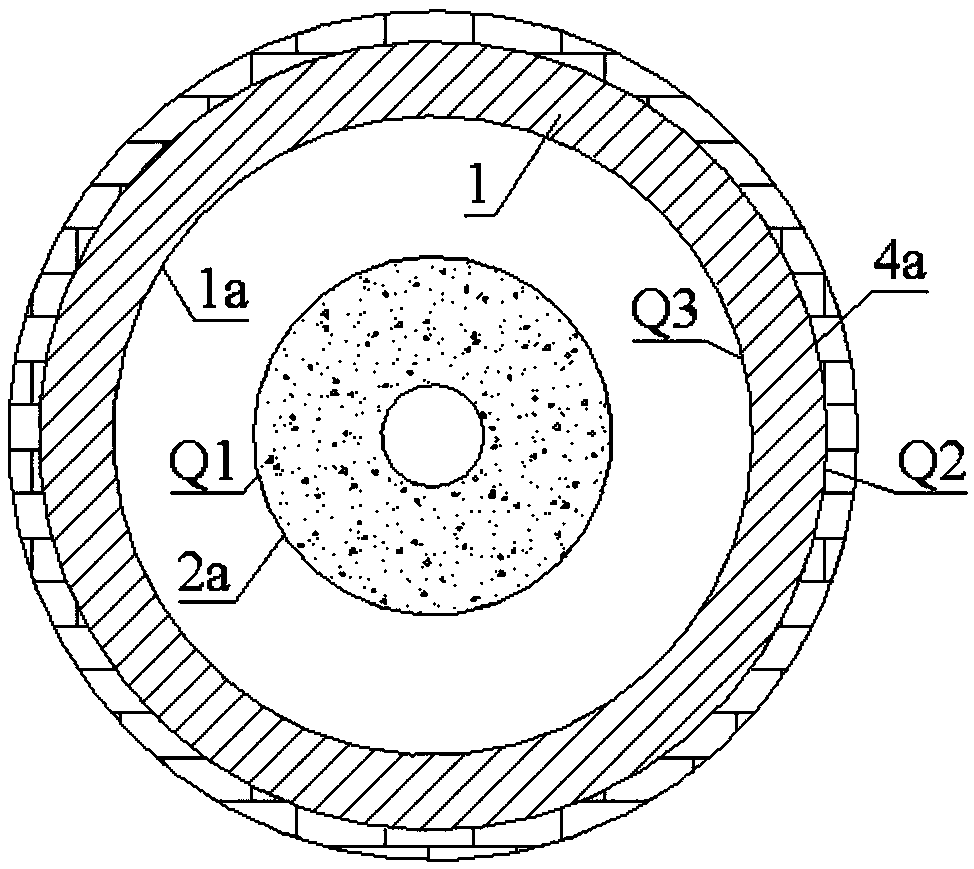

[0054] see figure 1 In the present embodiment, the pneumatic tire refers to the pneumatic tire 3 formed with the tire cavity 9 jointly by the inner surface 4a of the tire and the rim 2a; the pneumatic tire 3 is installed on the rim 2a and supported by the spokes 2b; the pneumatic tire 3 includes: The face portion 4, the bead portions 6 on the left and right sides, and the sidewall portions 5 on the left and right sides connecting the tread portion 4 and the bead portions 6 extend inside the tire between the left and right bead portions 6. The carcass 7 is provided with a belt 8 on the carcass outer peripheral side of the tread portion 4, and the pneumatic tire 3 is attached to a wheel so that the cavity of the pneumatic tire 3 is sealed via the rim 2a.

[0055] figure 1 The shown tire cavity is an annular tire cavity 9 formed jointly by the tire inner surface 4a and the rim 2a. The tire cavity resonance noise reduction device is a porous material installed on the tire inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com