Processing process of polygonal clamping connector at end of car checking fixture rotary shaft

A processing technology and technology of card joints, applied in the field of processing technology of multi-angle card joints, can solve the problems of card joints with many impurities and burrs, low quality, easy to scratch hands, etc., achieve good stability, improve work efficiency, The effect that is not easy to shake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be clearly and completely described below in conjunction with embodiments. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

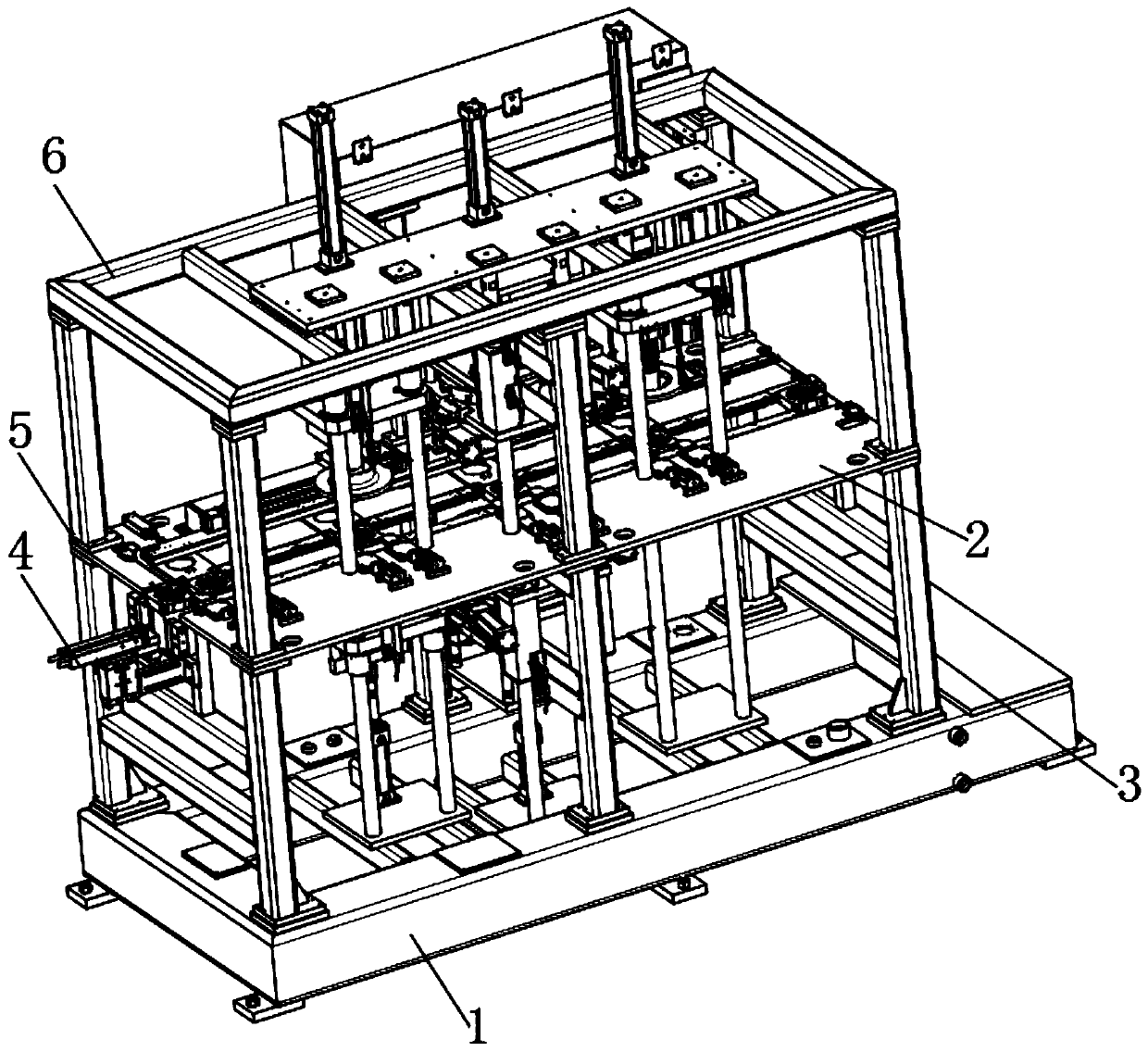

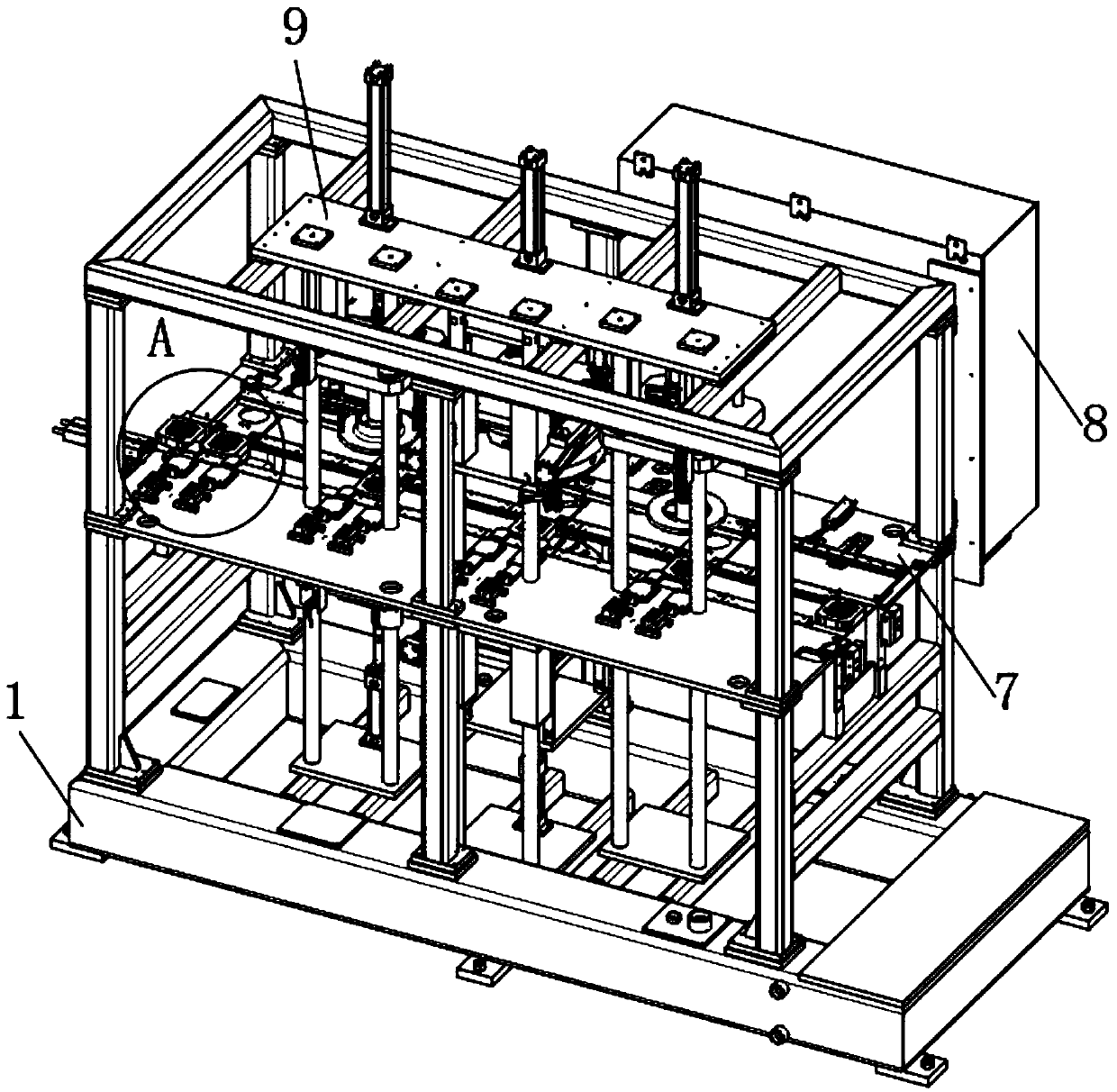

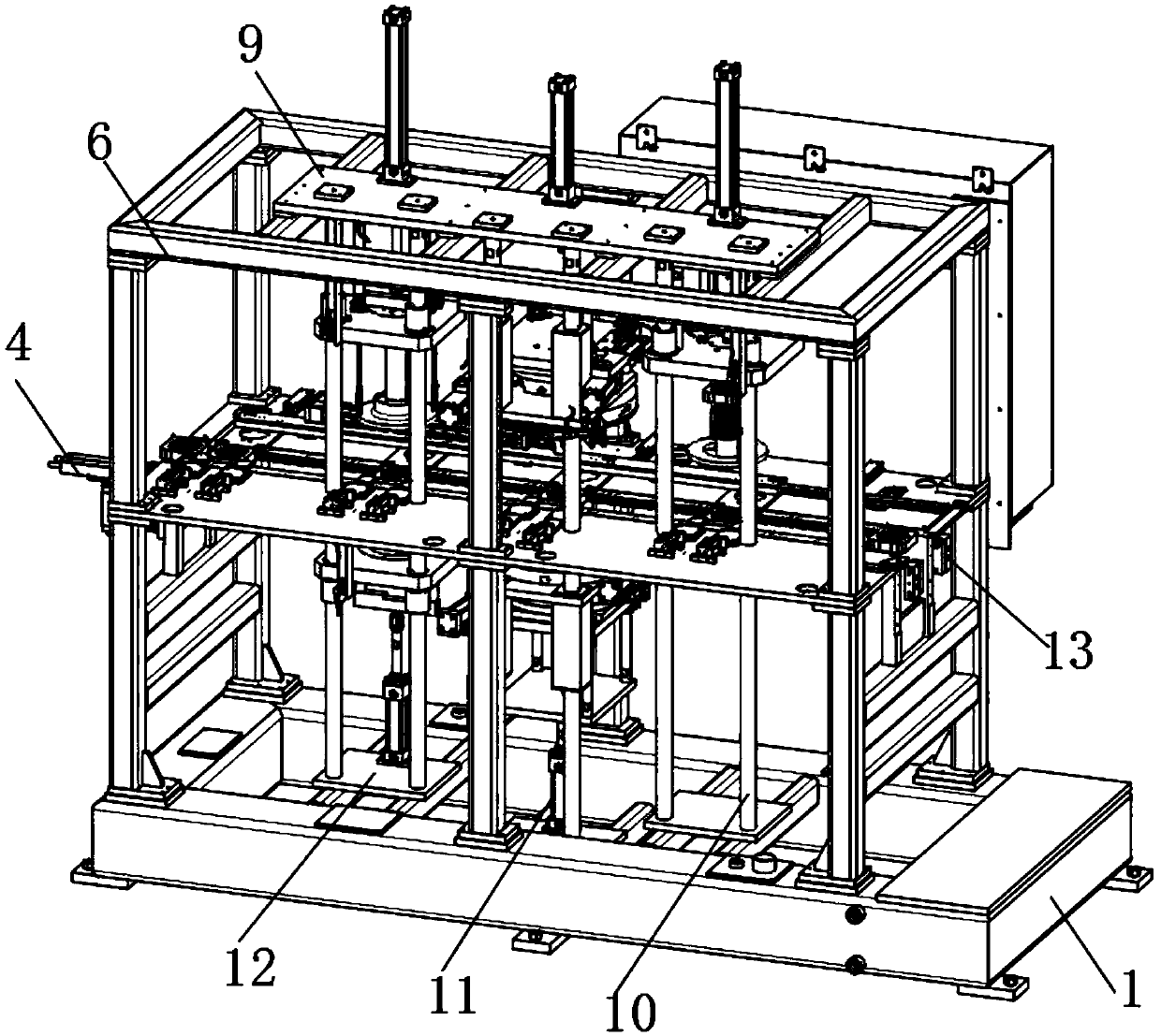

[0049] Such as Figure 1-14 As shown, a processing technology for the multi-angle clamp joint at the end of the rotating shaft of an automobile inspection tool includes the process steps of material selection-material cutting-clamping joint forming-end treatment. The specific steps are as follows:

[0050] S1. Material selection: select gray cast iron after quenching, the size of gray cast iron is 110mm*80mm*129.5mm;

[0051] S2. Material cutting: Cut the selected block gray cast iron inside the line cutting machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com