Pure silicon S-1 molecular sieve catalyst for packaging metal nanoparticles and preparing method and application of catalyst

A technology of metal nanoparticles and metal particles, applied in molecular sieve catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of catalyst activity, aromatic hydrocarbon selectivity and poor stability, long crystallization time, agglomeration, etc. It has both economic and market competitive advantages, good phenol conversion rate, low hydrogen consumption and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

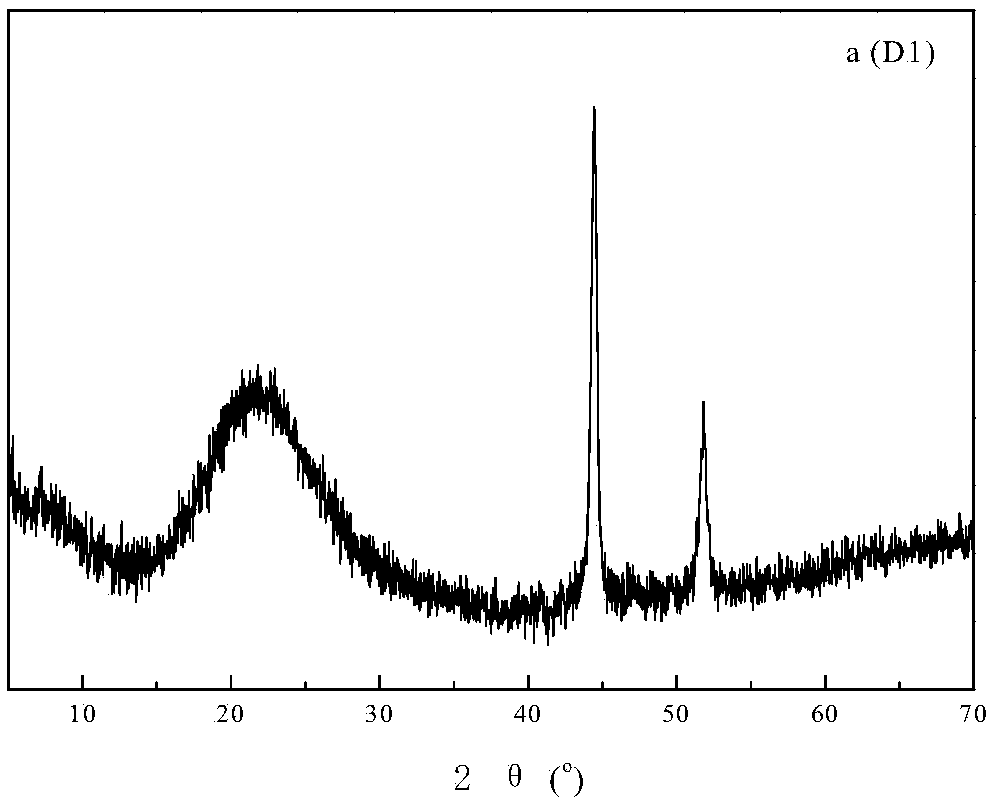

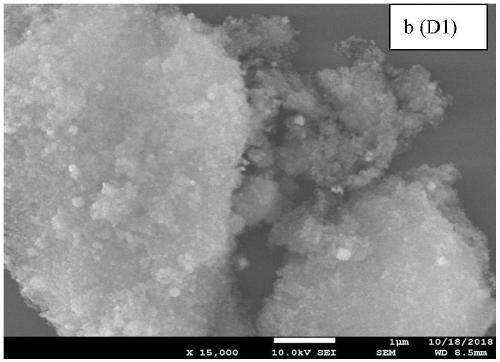

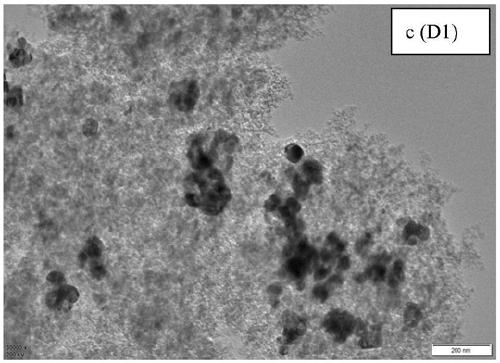

[0095] This embodiment illustrates the pure silicon S-1 molecular sieve catalyst and preparation method of the encapsulated metal Ni nanoparticles provided by the present invention:

[0096] (1) Mix ethyl orthosilicate, tetrapropylammonium hydroxide, and deionized water uniformly to obtain mixture A, wherein SiO 2 , TPAOH and H 2 The molar ratio of O is 1:0.15:30; the mixture A is hydrothermally treated at 80°C for 4h;

[0097] (2) Dissolve nickel nitrate in deionized water, then add ethylenediamine for complexation to obtain a purple transparent solution of nickel and ethylenediamine complexation; then, add this transparent complexed purple solution to step (1) hydrothermal treatment Among the obtained products, a mixture B was obtained, and the mixture B was hydrothermally treated at 60°C for 6h; wherein, the SiO in the mixture B 2 , TPAOH, H 2 The molar ratio of O and Ni is: 1:0.15:30:0.02, and the theoretical content of metal Ni is 2wt% Ni;

[0098] (3) Transfer the pr...

Embodiment 2

[0101] This example illustrates the pure silicon S-1 molecular sieve catalyst encapsulated with metal Ni nanoparticles provided by the present invention, its preparation method and its application in the catalyzed reaction of phenol.

[0102] 1. Synthesis of pure silicon S-1 molecular sieves encapsulated with metal Ni nanoparticles:

[0103] (1) Mix ethyl orthosilicate, tetrapropylammonium hydroxide, and deionized water uniformly to obtain mixture A, wherein SiO 2 , TPAOH and H 2 The molar ratio of O is 1:0.15:30; the mixture A is treated at 80° C. for 4 hours;

[0104] (2) Dissolve nickel nitrate in deionized water, then add ethylenediamine for complexation to obtain a purple transparent solution of nickel and ethylenediamine complexation; then, add this transparent complexed purple solution to step (1) hydrothermal treatment Among the obtained products, a mixture B was obtained, and the mixture B was hydrothermally treated at 60°C for 6h; wherein, the SiO in the mixture B ...

Embodiment 3

[0110] This embodiment illustrates the pure silicon S-1 molecular sieve catalyst and preparation method of the encapsulated metal Ni nanoparticles provided by the present invention:

[0111] (1) Mix ethyl orthosilicate, tetrapropylammonium hydroxide, and deionized water uniformly to obtain mixture A, wherein SiO 2 , TPAOH and H 2 The molar ratio of O is 1:0.15:30; the mixture A is hydrothermally treated at 80°C for 4h;

[0112] (2) Dissolve nickel nitrate in deionized water, and then add it dropwise to the product obtained in step (1) hydrothermal treatment to obtain mixture B, which is hydrothermally treated at 60°C for 6h; wherein, SiO in mixture B 2 , TPAOH, H 2 The molar ratio of O and Ni is: 1:0.15:30:0.02, and the theoretical content of metal Ni is 2wt% Ni;

[0113] (3) Transfer the product obtained in step (2) into a closed crystallization kettle, crystallize at 170.5°C for 12 hours, take it out, filter, dry, roast, and reduce to obtain pure silicon S encapsulated wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com