Anodized aluminum with dark gray color

An aluminum sheet, aluminum alloy technology, applied in anodizing, coating, surface reaction electrolytic coating, etc., can solve problems such as increasing the production cost of non-ferrous alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Alloy flakes of the present invention and three kinds of comparative alloy flakes were prepared, the compositions of which are detailed in Table 1. By casting the ingot at about 650°C, homogenizing the ingot at 525°C for a soaking time of less than 1 hour, hot rolling the homogenized ingot at 250-450°C for 10 minutes to produce a hot-rolled intermediate product, and at 150- The hot-rolled intermediate product was cold-rolled at 180° C. for 10 minutes to produce a cold-rolled intermediate product to prepare a sheet.

[0070] Table 1. Composition of alloying elements, total impurities up to 0.15% by weight, balance aluminum.

[0071]

Embodiment 2

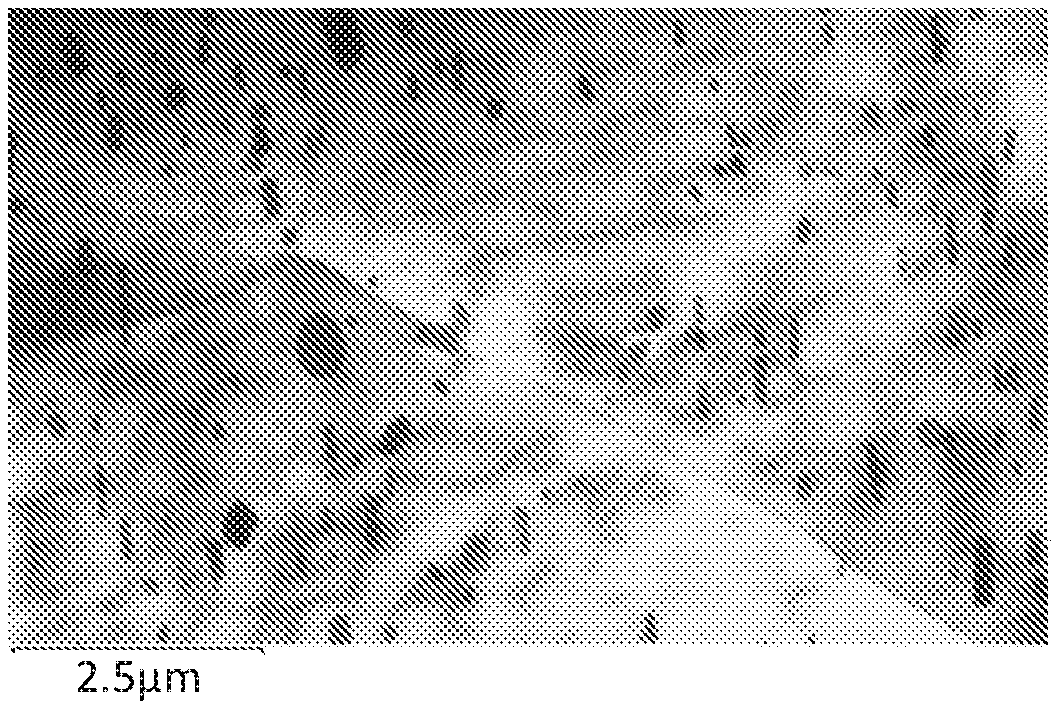

[0073] Aluminum flakes of Alloy 4 described in Example 1 and Comparative Alloys 1 and 2 were imaged with a scanning transmission electron microscope (STEM). Figure 1A with Figure 1B STEM images of Comparative Alloy 1 and Comparative Alloy 2, respectively. Figure 1C is the STEM image of Alloy 4. Alloy 4 exhibits a much higher dispersoid density than the comparative alloy. Alloy 3 has a lower dispersoid density than Alloys 1 and 2 and is therefore not shown.

Embodiment 3

[0075] Sheets of Comparative Alloys 1 and 2 and Alloy 4 prepared as described in Example 1 were alkaline etched with 10% sodium hydroxide solution and anodized to a 10 micrometer (μm) anodized layer thickness. The resulting cross-section of the anodized layer was imaged with a high-resolution scanning electron microscope (SEM). The SEM images of comparative alloys 1 and 2 and alloy 4 are shown in Figures 2A-2C . Such as Figure 2A As shown in, in these example alloys, the fine particles are Al 6 Fe and Mg 2 Si. The anodized aluminum flakes of Alloy 4 had a significantly darker gray color with many dispersoids visible (see Figure 2C ), while the two comparison anodized aluminum alloy flakes have light gray and less dispersoids (see Figure 2A-2B ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com