Essential oil reflux-type atomizer

An atomizer and essential oil technology, applied in the field of atomizers, can solve the problems of essential oil waste and poor atomization performance of essential oils, and achieve the effect of reducing essential oil waste and improving atomization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

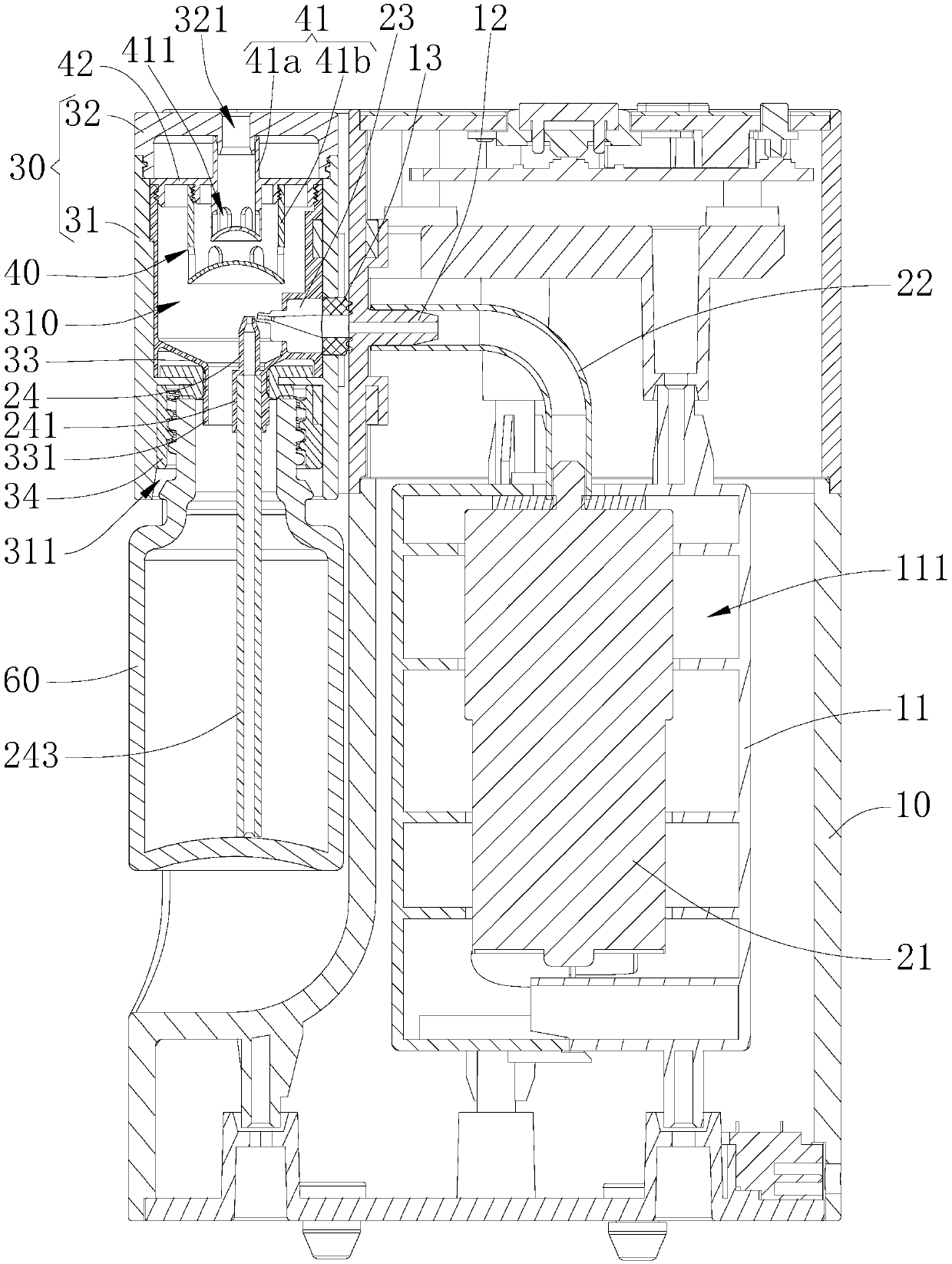

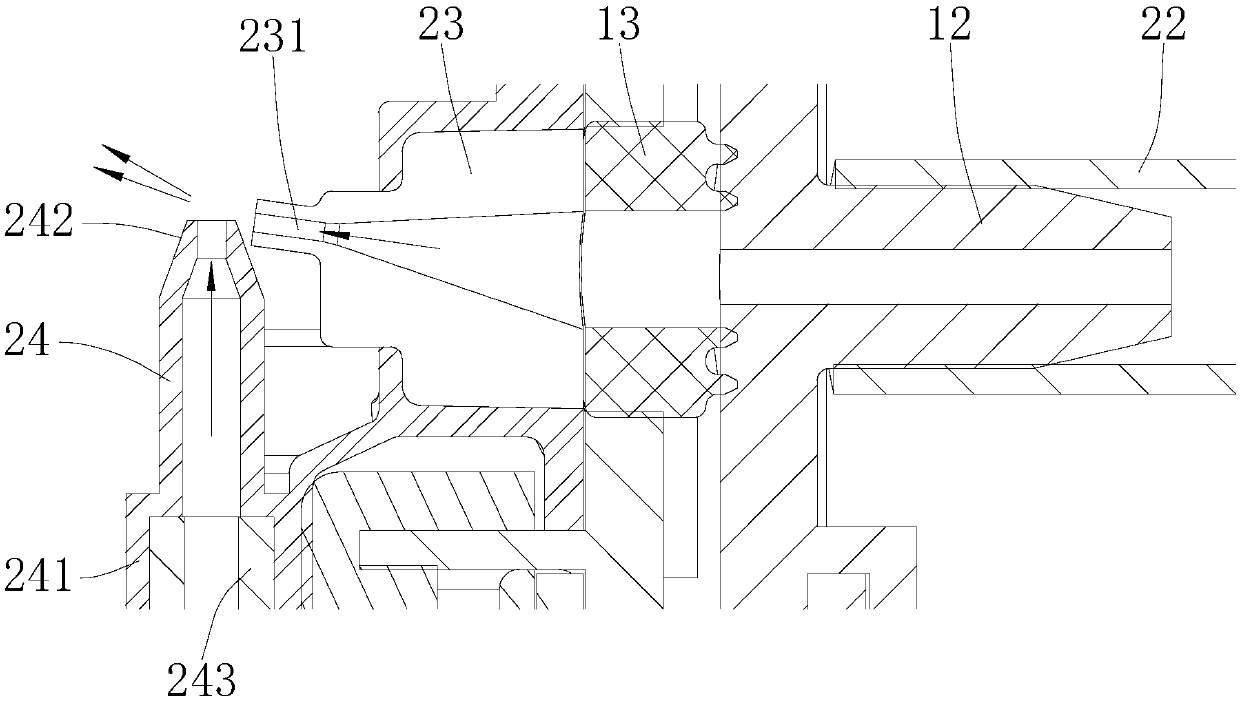

[0043] Please also refer to Figure 1 to Figure 3, the essential oil reflux atomizer provided by the present invention will now be described. The essential oil return atomizer includes a casing 10 , a casing 30 , an air pump 21 , an air pipe 22 , an air nozzle 23 , an oil nozzle 24 and a filter atomization mechanism 40 . The casing 30 is provided with an atomizing chamber 310 , and the casing 30 is provided with a mist outlet 321 connected to the atomizing chamber 310 . The lower end of the casing 30 is provided with a connection port 311 for connecting the essential oil bottle 60 . The housing 30 is installed on the casing 10 , the air pump 21 is installed in the casing 10 , and the air pump 21 is supported and protected by the casing 10 . One end of the air pipe 22 is connected with the air pump 21 , and the other end of the air pipe 22 is connected with the air nozzle 23 . The oil nozzle 24 is located at the position corresponding to the connection port 311, so that when ...

Embodiment 2

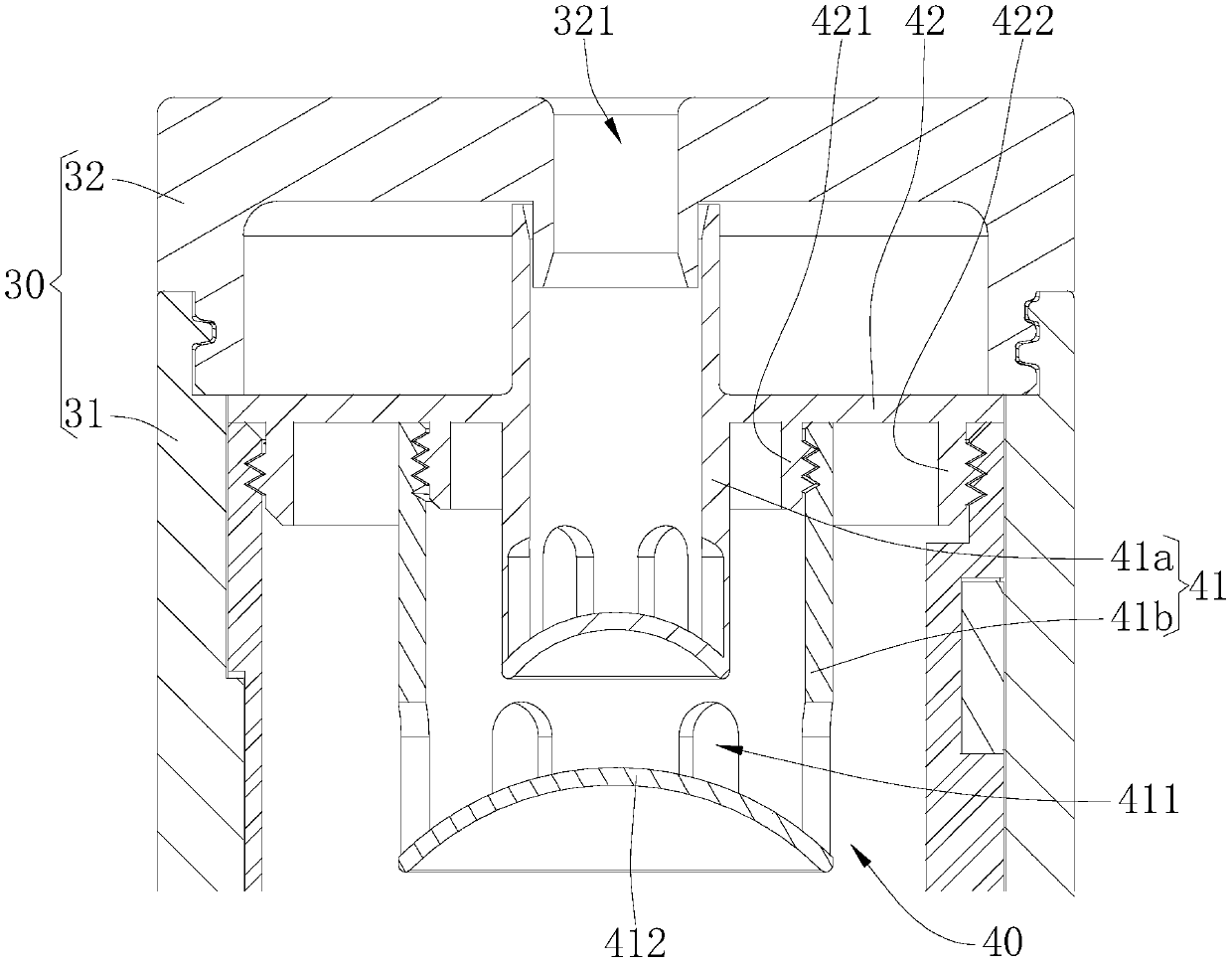

[0070] see Figure 4 and Figure 5 , the difference between the essential oil return atomizer of this embodiment and the essential oil return atomizer of Embodiment 1 is:

[0071] The side of the atomization chamber 310 facing the gas nozzle 23 is provided with a guide plate 332, the guide plate 332 is inclined to the axial direction of the outlet 231 of the gas nozzle 23, and the guide plate 332 is fixedly connected with the side wall of the atomization chamber 310. The guide plate 332 The air flow for guiding the injection of the air nozzle 23 flows upward. When the gas nozzle 23 ejects the airflow and extracts the essential oil to form a mixed airflow, the mixed airflow will flow towards the guide plate 332, and the guide plate 332 is provided to better guide the mixed airflow to the filter atomization mechanism 40, which is convenient The filter shell 41 filters the mixed air flow; at the same time, the guide plate 332 can also absorb and gather some essential oil drople...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com