Spiral nozzle

A helical, nozzle technology, used in fuel injection devices, engine components, machines/engines, etc., can solve the problem of limited atomization performance of nozzles, and achieve the effect of improving atomization performance and good atomization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

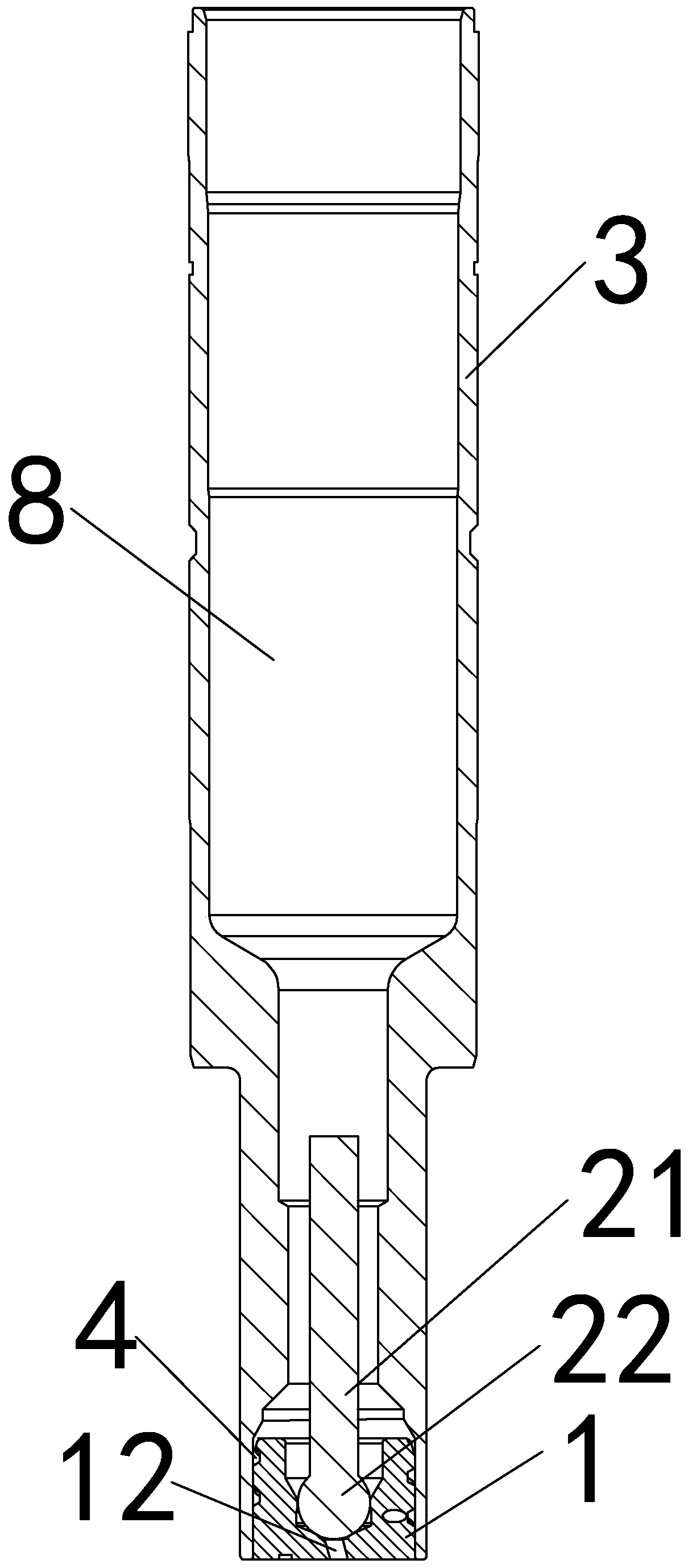

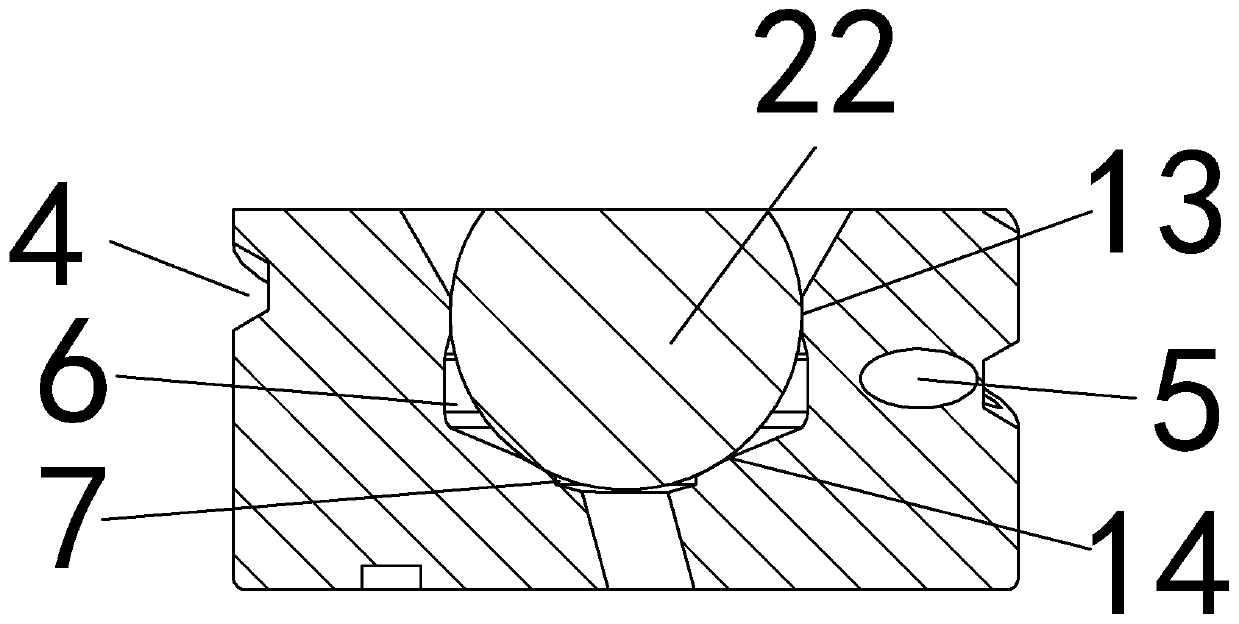

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. For a clearer disclosure, "upper" and "lower" in the present invention are defined relative to the direction of the medium. In the drawings, the position of the element that the medium passes first is defined as "upper", and the position of the element that the medium passes after is defined as "lower".

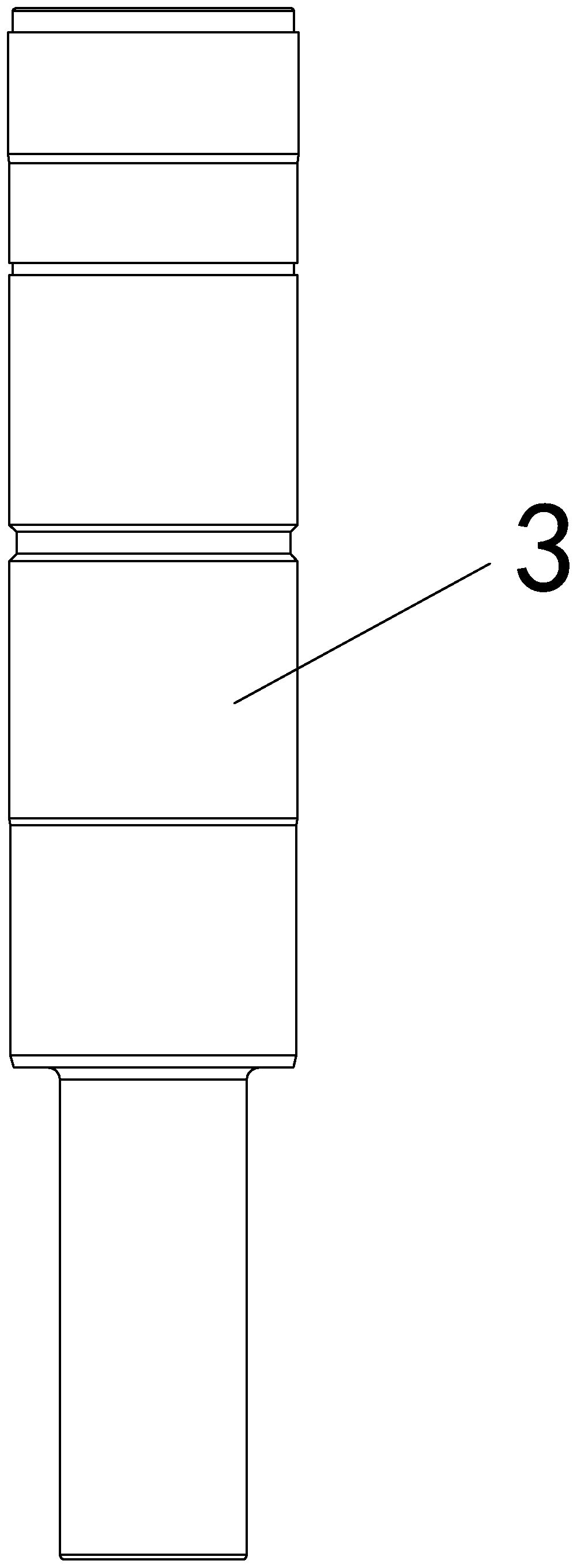

[0030] as attached figure 1 to attach Figure 6 As shown, a spiral nozzle of the present invention includes a valve body 3 , a valve seat 1 , a valve core 2 and an oil passage 8 . The valve body 3 is a tubular structure with a cavity inside, its upper end is provided with an oil inlet, and its lower end is in sealing connection with the valve seat 1 . The valve seat 1 is a cylindrical structure with a sphere placement cavity 11 inside. The valve seat 1 is provided with an atomization hole 12 at the center below the sphere placement cavity 11. hole. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com