An Optimization Method for Low-Temperature Thermal System

An optimization method and low-temperature thermal technology, applied in the petrochemical field, can solve problems such as slow solution speed, solution speed and accuracy cannot meet the complex and changeable low-temperature thermal system, and achieve rapid optimization speed, good economic benefits and energy-saving effects, and reduce operating costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

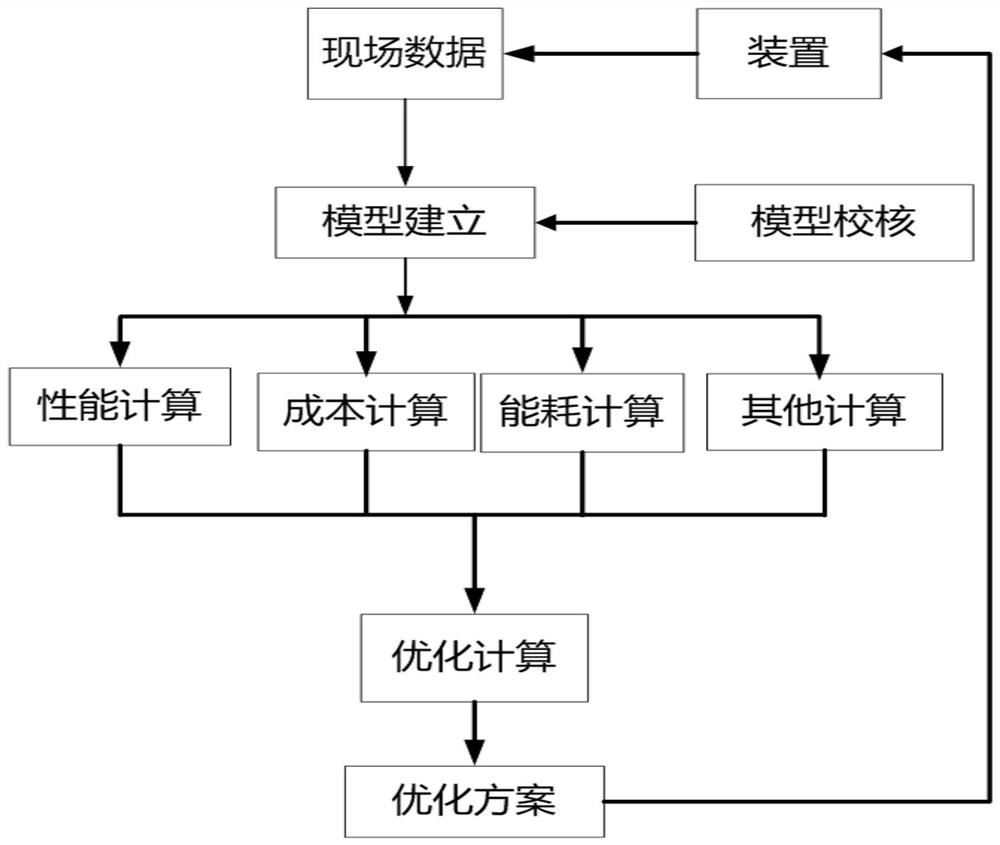

[0098] The first step is to collect and sort out the basic operating data, establish the basic mechanism model of the low-temperature thermal system, and simulate the actual working conditions.

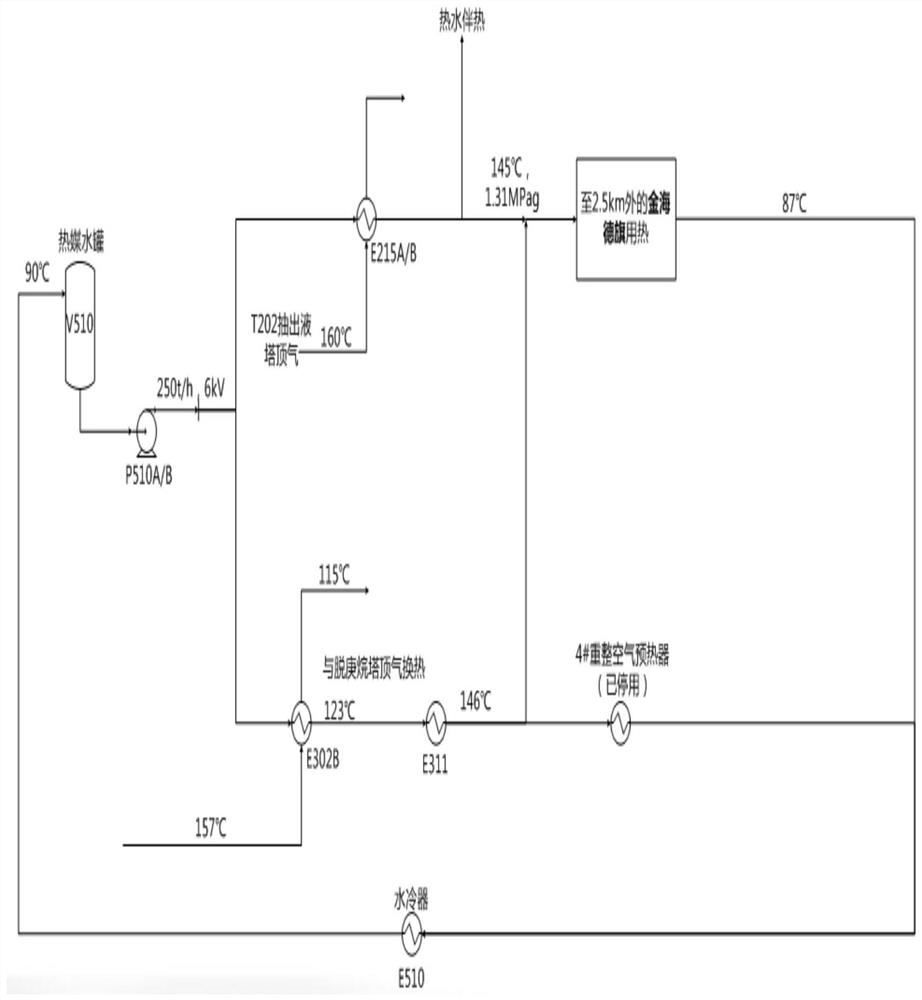

[0099] In this step, according to four sets of low-temperature thermal systems of a refining and chemical enterprise (such as figure 1 As shown), sort out the operating condition data of heat sources and heat sinks, verify the flow chart of low-temperature heat, establish the mechanism model of low-temperature heat flow, and calculate the parameters of medium physical properties and temperature.

[0100] Specifically:

[0101] (1) Based on the actual low-temperature heat process and data, including the flow, temperature and pressure data of the heat source, and the flow, temperature and pressure data of the heat sink, confirm the flow direction, heat transfer mode and other processes of the low-temperature heat source and heat sink, Establish mathematical mechanism models of four low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com