Coating composition for diffused bright-enhancement composite film laminating layer and diffused bright-enhancement composite film

A technology of coating composition and composite film, applied in optics, optical components, instruments, etc., can solve problems such as unfavorable promotion, achieve the effects of improving optical performance, reducing coating thickness, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

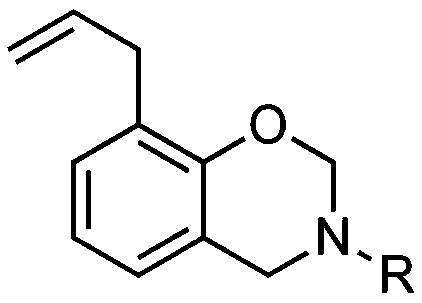

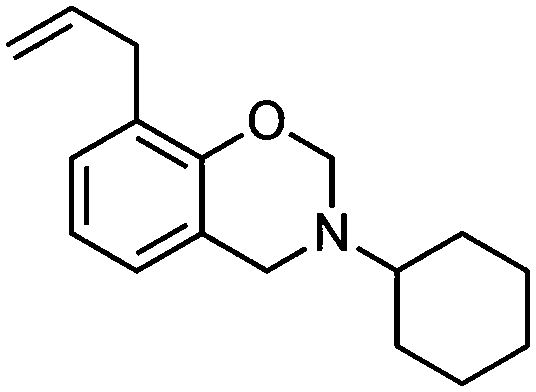

[0057] The preparation method of the coating composition provided by the present invention: mix the acrylate oligomer, allyl benzoxazine monomer, and photoinitiator according to the proportion, and then add ethyl acetate to adjust the viscosity to 11-13s , stirred evenly, and filtered to obtain a coating composition that can be coated on a substrate.

[0058] Further, attention should be paid to shading treatment during the preparation process.

[0059] Further, the viscosity of the coating composition is measured using a Tu-4 cup.

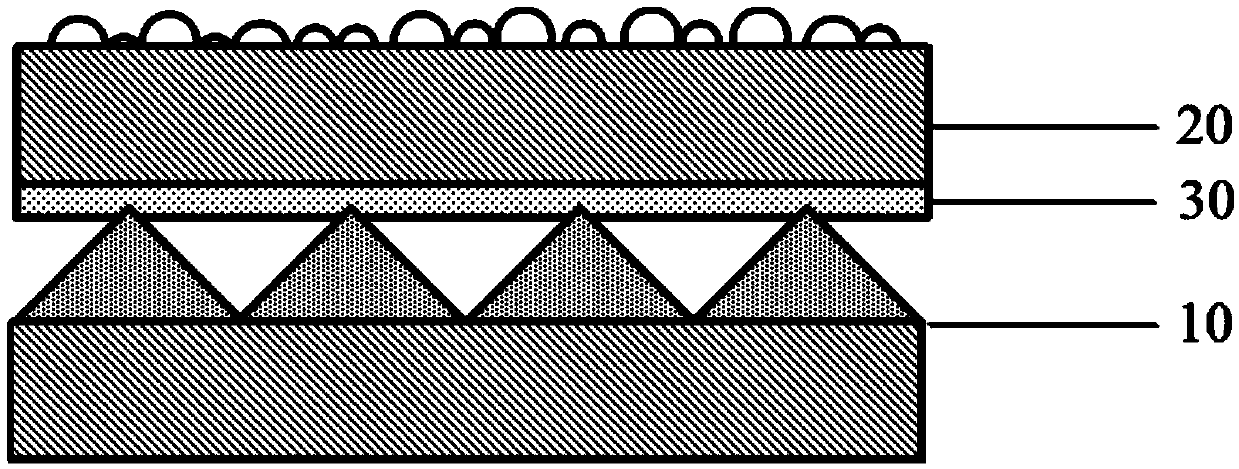

[0060] The method of using the coating composition provided by the present invention as a laminating layer of a diffusion-enhanced composite film uses a wire bar coater to evenly coat the uniformly mixed coating composition on the blank substrate on the back of the diffusion layer at 100°C Bake for 3 minutes, remove the solvent, then compound the lower prism layer with a composite roller, and then perform UV curing under a UV curing lamp, the cur...

Embodiment 1

[0067] The invention provides a coating composition used for a bonding layer of a diffusion and enhancement composite film and a diffusion and enhancement composite film.

[0068] The coating composition comprises: novolac epoxy acrylate 625C-45 added in an amount of 64g, aliphatic polyurethane hexaacrylate 6144-100 added in an amount of 16g, dodecyl allyl benzoxazine monomer added in an amount of It is 20g, and the addition amount of photoinitiator is 2g. The photoinitiator is a combination of Irgacure 184 and Irgacure754, and the mass ratio of Irgacure 184 to Irgacure 754 is 1:1.

[0069] The haze of the diffusion layer was 88%.

[0070] The micro-prism structure of the prism layer has a height of 35 μm and an angle of 90°. The distance between the peaks of two adjacent prism structures of the prism layer is 70 μm.

[0071] Mix the coating composition evenly, then coat it on the substrate on the back of the diffusion layer, bake it at 100°C for 3 minutes, then compound th...

Embodiment 2

[0073] The coating composition comprises: novolac epoxy acrylate 625C-45 added in an amount of 64g, aliphatic polyurethane hexaacrylate 6145-100 added in an amount of 16g, dodecyl allyl benzoxazine monomer added in an amount of It is 20g, and the addition amount of photoinitiator is 2g. The photoinitiator is Irgacure 184 and Irgacure754, and the mass ratio of Irgacure 184 and Irgacure 754 is 1:1.

[0074] All the other experimental conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com