A pull-out method for evaluating the early freezing performance of concrete

A concrete and drawing technology, which is applied to instruments, measuring devices, mechanical devices, etc., can solve the problems of difficulty in timely and accurate evaluation of the early freezing damage of negative temperature concrete and poor quality of construction projects in winter, and achieve a scientific and reasonable calculation method. , Guarantee construction quality, scientific and reasonable effect of operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

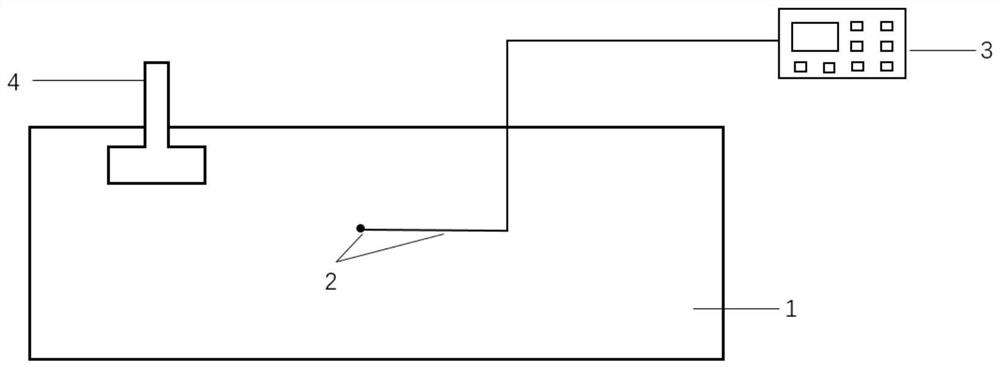

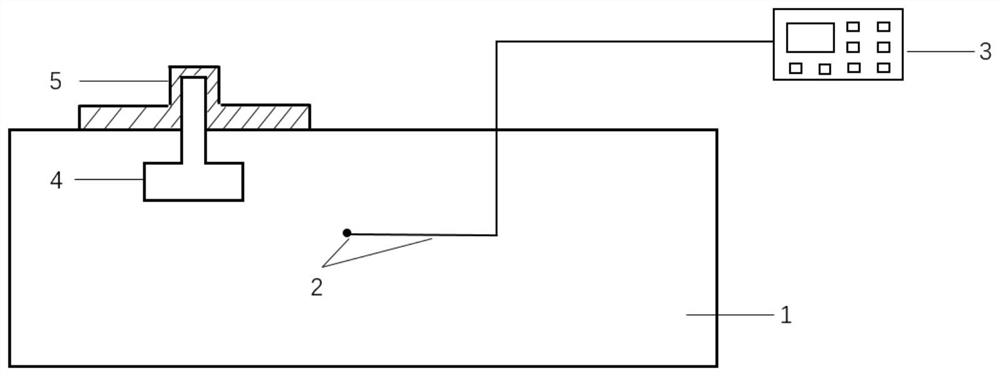

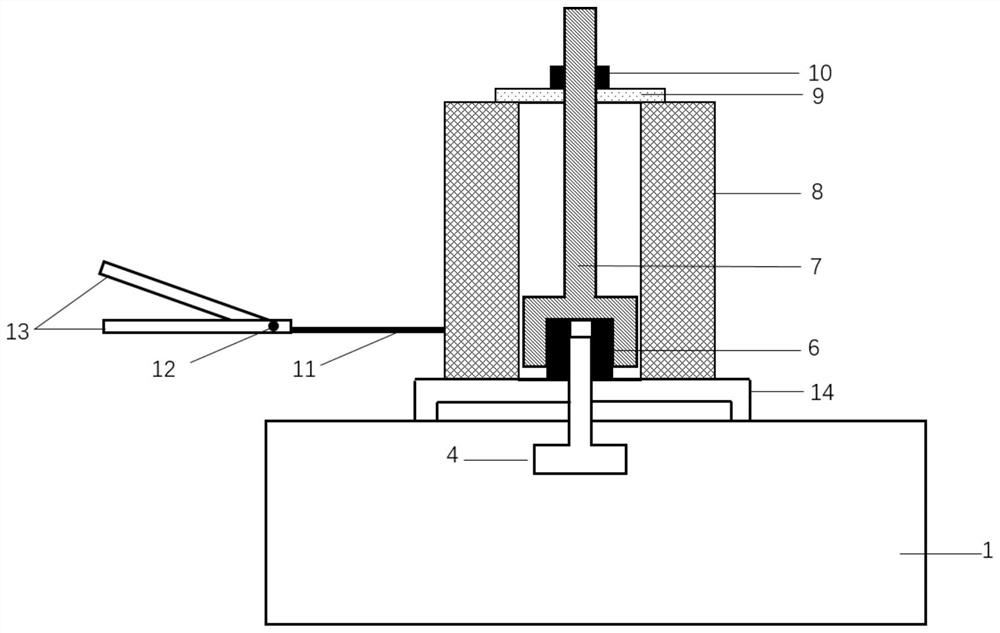

[0045] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 To illustrate this embodiment, select the adjacent concrete area I and concrete area II in concrete engineering 1, obtain the temperature rise time Δt from the concrete area I to the ice-free state, and heat the concrete area I according to the temperature rise time Δt, and the heating Pull-out tests were performed on the final concrete area I and unheated concrete area II, and the early freezing performance of concrete was evaluated by comparing the pull-out force values.

[0046] Further, when the concrete project 1 is poured, a plurality of first anchor rods 4 are pre-embedded in the concrete area I, and a plurality of second anchor rods are pre-embedded in the concrete area II, and in areas other than the concrete area I and the concrete area II The embedded temperature sensor 2 is used as the temperature measuring point, and the temperature sensor 2 is connected with the temp...

specific Embodiment approach 2

[0067] Specific implementation mode two: combination figure 1 , figure 2 , image 3 and Figure 4 To describe this embodiment, the heating power of the constant power heating device 5 is 90W. Since the concrete cannot fully absorb the energy provided by the constant power heating device 5 during actual operation, and considering the heat transfer process from the heated area to the surroundings, the heating power needs to be corrected with a correction coefficient according to the temperature of the concrete when it is heated. The acquisition of the correction coefficient needs to be obtained through pre-experiment.

[0068] The negative temperature is divided into intervals, and the correction coefficient is taken for each temperature interval, and the number of temperature intervals required for the pre-experiment is reasonably determined according to the multi-year winter minimum temperature data at the location of the concrete project 1. Starting from 0°C, each temper...

specific Embodiment approach 3

[0086] Specific embodiment three: this embodiment is a further limitation of specific embodiment one or two. When concrete engineering 1 is poured, the temperature sensor 2 is pre-embedded in the area other than the concrete area I and the concrete area II as a temperature measuring point, and the temperature sensor 2 and The temperature recorder 3 is connected to record the concrete temperature Ti and the corresponding time at this temperature as Δd i . The temperature Ti and the corresponding time at this temperature is Δd i It is determined according to the age requirement of evaluating concrete engineering 1. For example, to evaluate the freezing performance of concrete engineering 1 within 7 days, you can measure and obtain the temperature Ti within 7 days and the corresponding time at this temperature is Δd i .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific heat capacity | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com