Magneto-sensitive rubber with controllable adhesion characteristics, and preparation method and test device thereof

A technology of magnetic-sensitive rubber and characteristics, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems such as the controllable adhesion characteristics of magnetic-sensitive rubber.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

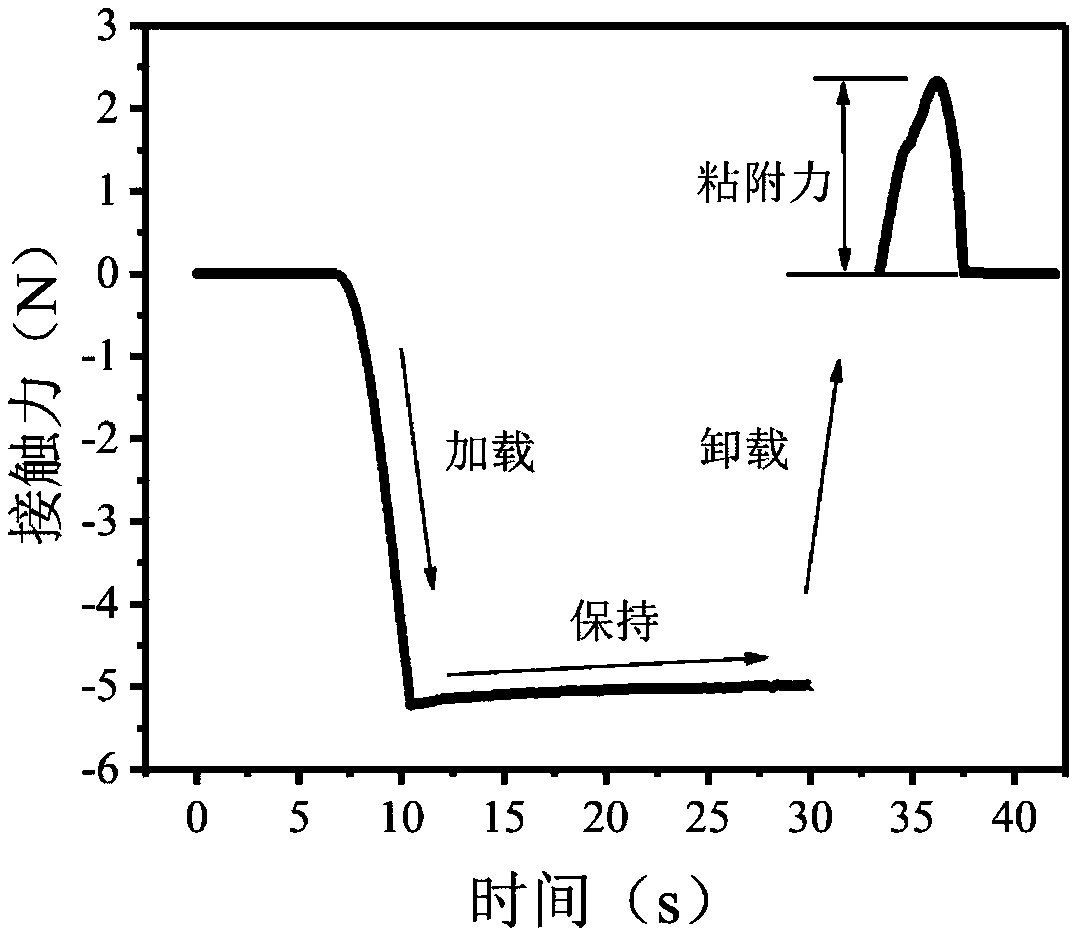

[0043] Prepare isotropic magnetic-sensitive rubber with controllable adhesion properties, and study the effects of pull-out speed, pressing time, and magnetic field strength on the adhesion properties of isotropic magnetic-sensitive rubber:

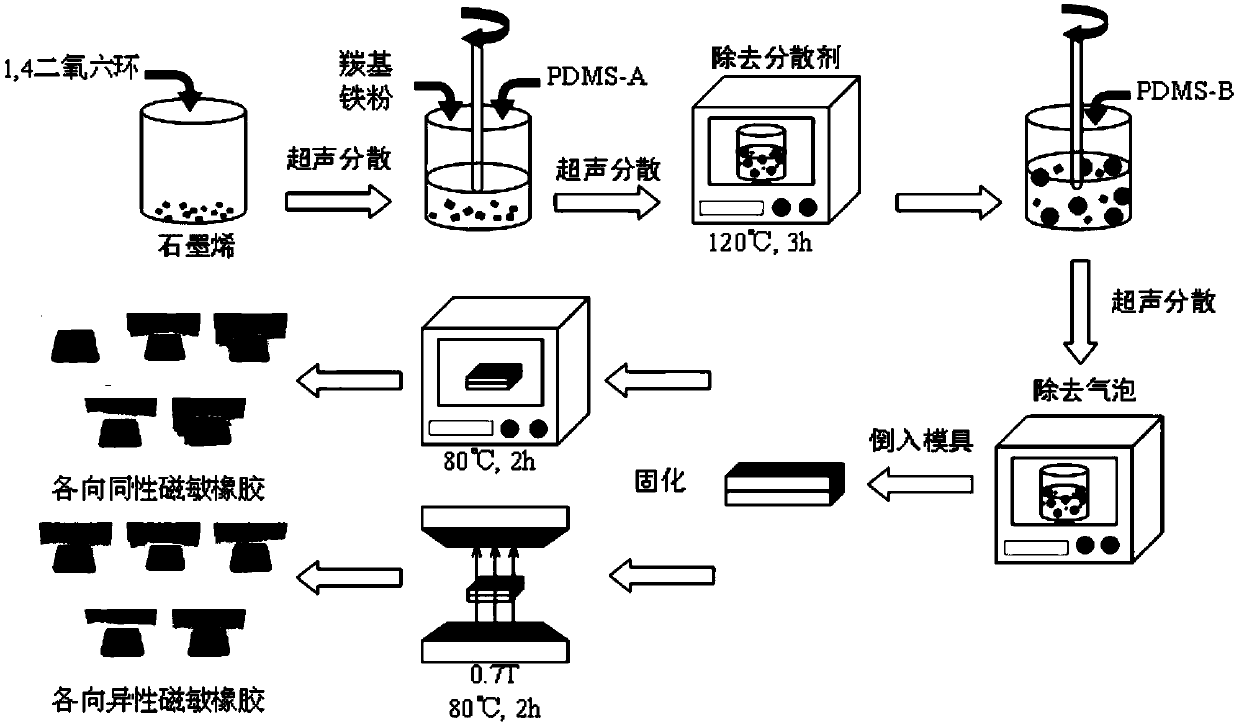

[0044] 1. According to the following process (such as figure 1 shown) to prepare sample 1:

[0045] a. Add 0.4g reduced graphene oxide and 3.3mL (3.4g) 1,4-dioxane to the beaker, and ultrasonically disperse for 30min;

[0046] b. Continue to add 40g of PDMS-A component and 8.9g of carbonyl iron powder particles into the beaker, perform ultrasonic dispersion treatment and mechanical stirring for 1h, transfer to a drying oven at 120°C to dry until 1,4-dioxane is completely removed Then take it out and cool it for later use;

[0047] c. Continue to add 4g of PDMS-B component and stir for 5 minutes to make it evenly mixed and put it into a vacuum drying oven with a vacuum degree of 101Pa for 10 minutes to completely remove the air bubbles i...

Embodiment 2

[0062] Prepare anisotropic magnetic-sensitive rubber with controllable adhesion properties, and study the effects of pull-out speed, pressing time, and magnetic field strength on the adhesion properties of anisotropic magnetic-sensitive rubber:

[0063] 1. According to the following process (such as figure 1 shown) to prepare sample 6:

[0064] a. Add 0.4g reduced graphene oxide and 3.3mL (3.4g) 1,4-dioxane to the beaker, and ultrasonically disperse for 30min;

[0065] b. Continue to add 40g of PDMS-A component and 8.9g of carbonyl iron powder particles into the beaker, perform ultrasonic dispersion treatment and mechanical stirring for 1h, transfer to a drying oven at 120°C to dry until 1,4-dioxane is completely removed Then take it out and cool it for later use;

[0066] c. Continue to add 4g of PDMS-B component and stir for 5 minutes to make it evenly mixed and put it into a vacuum drying oven with a vacuum degree of 101Pa for 10 minutes to completely remove the air bubbl...

Embodiment 3

[0081] Preparation of an isotropic magnetically sensitive rubber with controlled adhesion properties:

[0082] a. Add 0.6g reduced graphene oxide and 3.8mL (4.0g) 1,4-dioxane to the beaker, and ultrasonically disperse for 20min;

[0083] b. Continue to add 23g of PDMS-A component and 69.6g of carbonyl iron powder particles into the beaker, perform ultrasonic dispersion treatment and mechanical stirring for 1.2h, transfer to a drying oven at 110°C to dry until 1,4-dioxane is completely removed After ringing, remove and cool for later use;

[0084]c. Continue to add 2.3g of PDMS-B component and stir for 10 minutes to make it evenly mixed, then put it into a vacuum drying oven with a vacuum degree of 101Pa and dry for 20 minutes to completely remove the air bubbles in the mixture;

[0085] d. Get the mixture that removes air bubbles in step c and pour it into an acrylic plate mold, and seal the mold for later use;

[0086] e. Magnetic-sensitive rubber curing molding: put the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com