One-way flow passage switching alloy valve

A unidirectional flow and alloy technology, applied in the direction of wellbore/well valve device, earthwork drilling, wellbore/well components, etc., can solve the problems of increased energy consumption, operation fluctuation and loss of decompression device, and achieve saving The effect of manufacturing mold cost, convenient assembly or disassembly, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

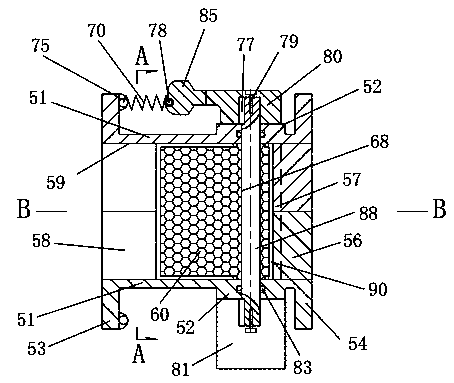

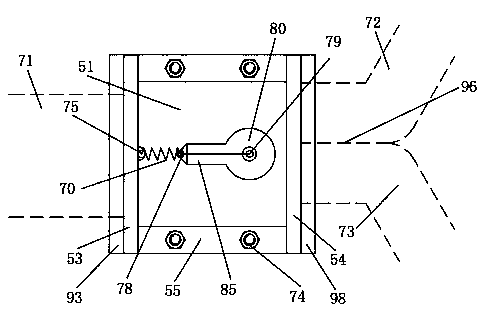

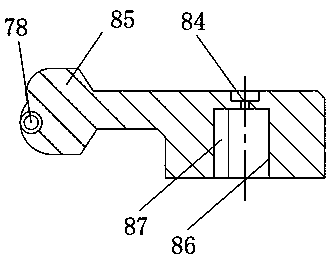

[0045] In the picture:

[0046] 51. Upper and lower symmetrical half-open valve body; 52. Through hole of upper and lower bosses; 53. Half flange at the inlet end; 54. Half flange at the outlet end; 55. Half-open split plane; Sealing wall; 58. Vertical half side; 59. Horizontal bottom plane; 60. Swing valve core; 61. Long groove up and down the valve chip; 62. Short groove up and down the valve core column; 64. Leaf groove of the valve core; 65. Valve core Cylindrical groove; 66, spool cylinder; 67, spool upper and lower circular grooves; 68, spool through hole; 69, spool swing leaf; 70, locking spring; 71, water inlet square mouth pipe; 72, water outlet One pipe; 73, second water outlet pipe; 74, split fastening assembly; 75, valve body spring seat; 76, valve stem keyway; 77, transmission flat key; 78, wrench spring seat; 79, wrench fastening screw; 80. Switching wrench; 81. Remote actuator; 82. Half-open connection hole; 83. Valve stem hole sealing groove; 84. Step through ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com