A high-frequency dynamic load rock breaking tool and its application method

A dynamic load and rock-breaking technology, applied in the field of oil and gas exploration, can solve the problems of increased energy, low drilling efficiency, and high cost, and achieve the effects of maintaining stable and balanced torque, improving drilling quality, and reducing drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to understand the content of the present invention more clearly, it will be described in detail with reference to the drawings and embodiments.

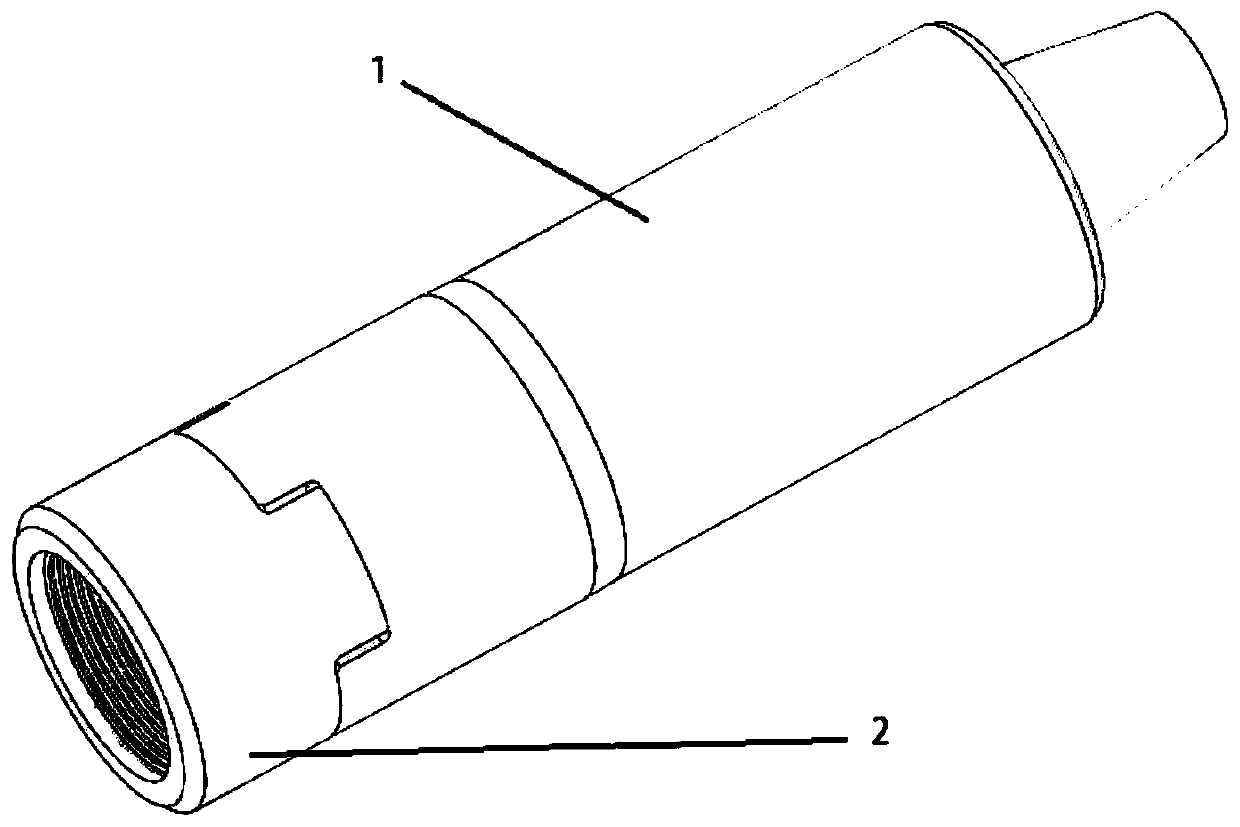

[0034] as attached figure 1 It is an overall schematic diagram of the present invention, the 120° interlocking gap connection between the shell 1 and the lower joint 2 can be seen from the outside, that is, the outer part of the inverted staggered locking mechanism 4 includes three sets of identical interlocking structures.

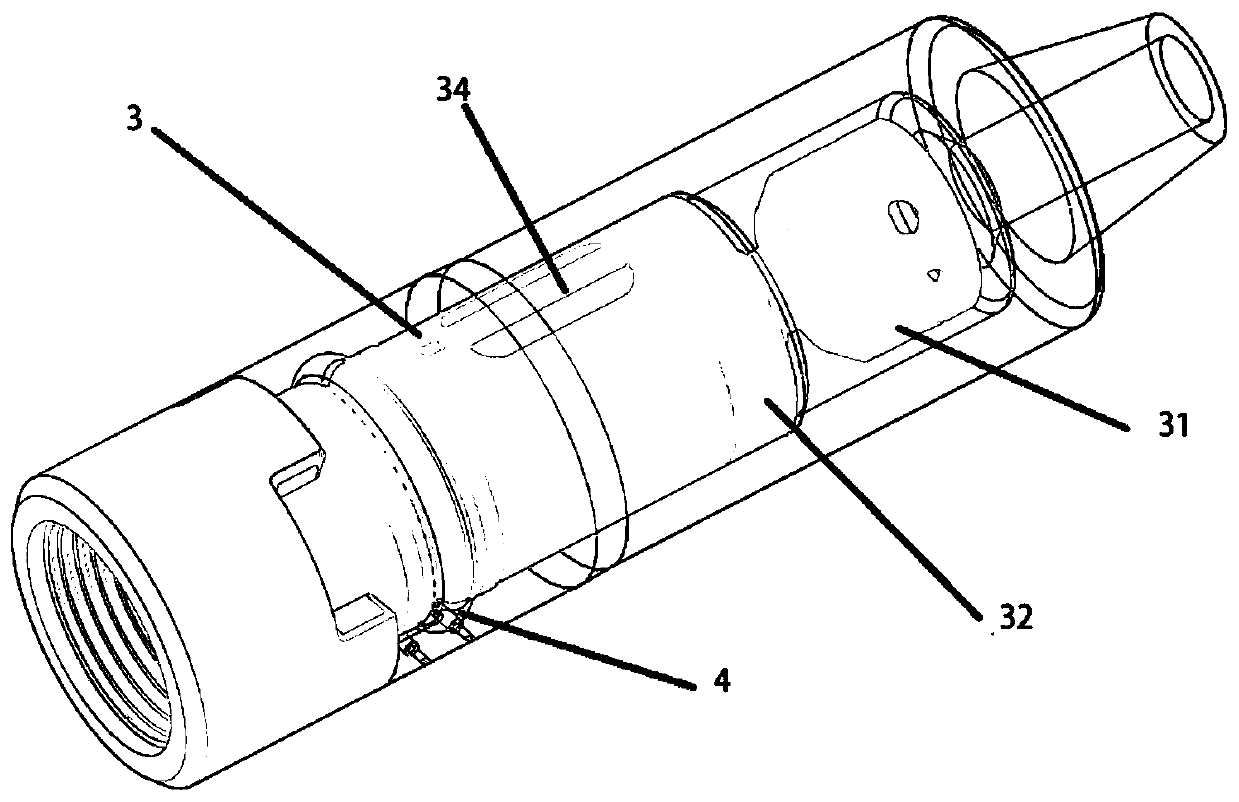

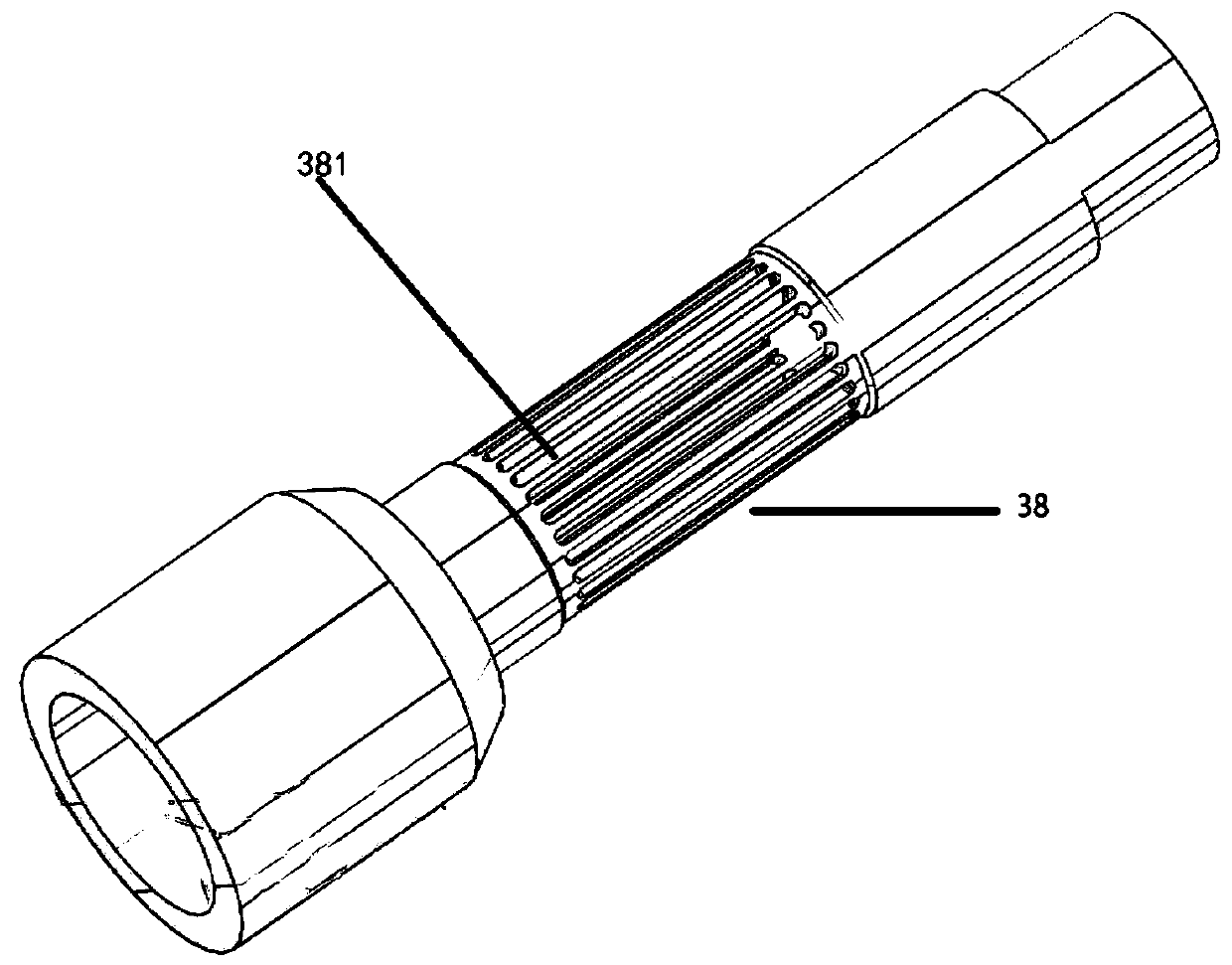

[0035] as attached figure 2 It is a schematic diagram of the perspective structure of the present invention. It can be seen that the fixed bearing connection between the bottom end of the impact system 3 and the lower joint 2, that is, the inner part of the undercut staggered locking mechanism 4, is attached Figure 4 It is a structural schematic diagram of the fixed bearing connection structure. The top of the shock system 3 is connected to the shunt 31 ; the shock system 3 also includes a to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com