A preparation method of a chemical inhibitor for preventing lignite spontaneous combustion

A chemical inhibitor and lignite technology, applied in the field of flame retardants, can solve problems such as insufficient environmental protection, and achieve the effects of convenient use, good inhibitory effect, and excellent inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

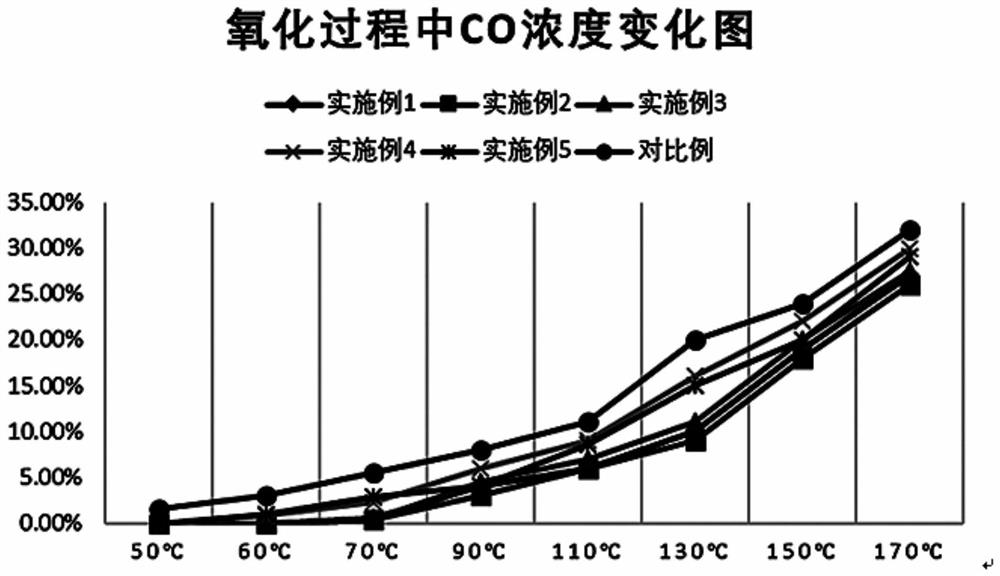

Examples

Embodiment 1

[0034] A preparation method for preventing lignite from spontaneous combustion, the steps are as follows:

[0035] (1) The phenol-resistant Brevibacterium parvus and Cellulomonas hygrospores were respectively expanded and cultivated to a cell concentration of 10 9 cfu / g, mixing the phenol-resistant Brevibacterium and Cellulomonas hygrogena according to a mass ratio of 1:2 to obtain a mixed strain;

[0036] (2) aseptically inoculate the mixed strains of step (1) gained into the liquid fermentation medium after the sterilization treatment, the weight ratio of the liquid fermentation medium and the mixed strains is 15: 1, the mixed strains inoculated The liquid fermentation medium was placed in constant temperature and continuous fermentation at 140rpm and 27°C for 55 hours;

[0037] The formula of described liquid fermentation medium is as follows: in the liquid fermentation medium of every 1L, contain 20g peptone, the yeast powder of 6g, 12g potato starch, the glucose of 6g, 1...

Embodiment 2

[0045] A preparation method for preventing lignite from spontaneous combustion, the steps are as follows:

[0046] (1) The phenol-resistant Brevibacterium parvus and Cellulomonas hygrospores were respectively expanded and cultivated to a cell concentration of 10 9 cfu / g, mixing the phenol-resistant Brevibacterium and Cellulomonas hygrogena according to a mass ratio of 1:3 to obtain a mixed strain;

[0047] (2) aseptically inoculate the mixed strains of step (1) gained into the liquid fermentation medium after the sterilization treatment, the weight ratio of the liquid fermentation medium and the mixed strains is 15: 1, the mixed strains inoculated The liquid fermentation medium was placed at 140rpm and 27°C for constant temperature and continuous fermentation for 55 hours, and then placed at 25-35°C fluctuating room temperature for 100 days;

[0048] The formula of described liquid fermentation medium is as follows: in the liquid fermentation medium of every 1L, contain 20g p...

Embodiment 3

[0056] A preparation method for preventing lignite from spontaneous combustion, the steps are as follows:

[0057] (1) The phenol-resistant Brevibacterium parvus and Cellulomonas hygrospores were respectively expanded and cultivated to a cell concentration of 10 9 cfu / g, mixing the phenol-resistant Brevibacterium and Cellulomonas hygrogena according to the mass ratio of 1:2.5 to obtain the mixed strain;

[0058] (2) aseptically inoculate the mixed strains of step (1) gained into the liquid fermentation medium after the sterilization treatment, the weight ratio of the liquid fermentation medium and the mixed strains is 15: 1, the mixed strains inoculated The liquid fermentation medium was placed at 140rpm and 27°C for constant temperature and continuous fermentation for 55 hours, and then placed at 15-25°C fluctuating room temperature for 100 days;

[0059] The formula of described liquid fermentation medium is as follows: in the liquid fermentation medium of every 1L, contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com