Preparation method and application of polysilazane material

A technology of polysilazane and synthesis method, applied in the direction of coating and the like, can solve the problems of inability to meet the application of polysilazane, harsh conditions, low molecular weight of polysilazane polymer, etc., so as to improve the polysilazane material. Molecular weight, mild reaction conditions, effect of promoting cross-linking reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

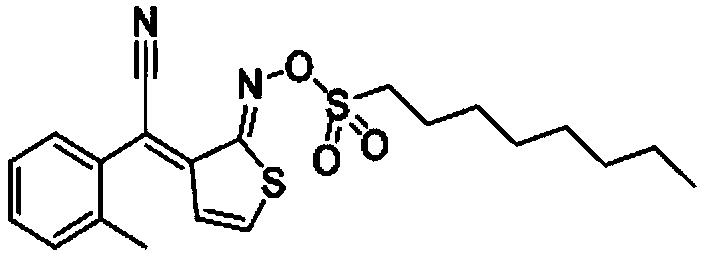

Image

Examples

preparation example 1

[0011] Preparation example 1: Preparation of polysilazane pyridine solution for experiment:

[0012] Add dry pyridine to a glass reactor with a gas conduit, a condenser, and a stirrer, and add dichlorosilane to form a white solid complex (SiH 2 Cl 2 -2C 5 h 5 N), while stirring, introduce ammonia gas through the drying tube to carry out the ammonolysis reaction for 2-3h. After the reaction is completed, the by-product ammonium chloride is removed by vacuum filtration to obtain a polysilazane pyridine solution.

Embodiment 1

[0014] Dilute the polysilazane pyridine solution of Preparation Example 1 with an organic mixed solvent of pyridine and xylene, dilute to the second polysilazane solution with a solid content of polysilazane of 5%, add polysilazane mass 0.3% of the initiator azobisisobutyronitrile, after stirring and dissolving, pass a dry nitrogen flow into the reaction system, heat to 40°C and stir for half an hour, then raise the temperature to 50°C, and react at 50°C for 4 hours Cool to room temperature, obtain high molecular weight polysilazane material by distillation replacement.

Embodiment 2

[0016] Dilute the polysilazane solution of Preparation Example 1 with an organic mixed solvent of pyridine and xylene, dilute to the second polysilazane solution with a solid content of polysilazane of 10%, and add 0.3% of the mass of polysilazane % of the initiator azobisisobutyronitrile, stirred and dissolved, passed a dry nitrogen flow into the reaction system, heated to 50°C, stirred and reacted for 4 hours, cooled to room temperature, and obtained high molecular weight polysilazane material by distillation replacement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com