Preparation method of chloroacetaldehyde oxime

An acetaldehyde oxime, chlorination technology, applied in the directions of oxime preparation, organic chemistry, etc., can solve the problems of increasing waste water treatment cost and environmental protection pressure, difficult to control the chlorination reaction process, difficult to realize industrial production and utilization, etc., and achieve high efficiency. Industrial production, good application value and application prospects, and the effect of improving reaction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

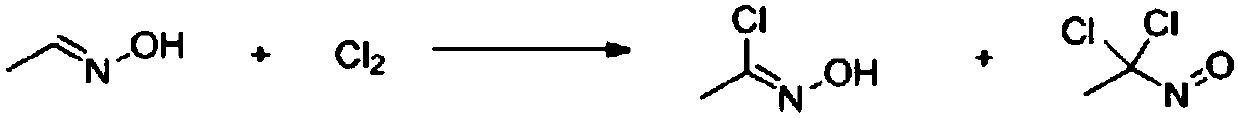

[0030] A kind of preparation method of chloroacetaldehyde oxime, take acetaldehyde oxime solution and chlorine gas as raw material, prepare chloroacetaldehyde oxime with microreactor as reaction device, comprise the following steps:

[0031] (1) Preparation of acetaldehyde oxime solution: 120 g of acetaldehyde oxime (mass concentration ≥ 99.0%, 2.0 mol), 175 g of methanol and 5 g of water were uniformly mixed to obtain an acetaldehyde oxime solution.

[0032] (2) Select a microreactor with three reaction templates. The acetaldehyde oxime solution prepared in the step (1) is injected in the microreactor with the speed of 300g / h by metering pump, feeds chlorine into microreactor with the speed of 156g / h simultaneously and reacts, in the reaction process Control the mol ratio of acetaldehyde oxime and chlorine to be 1: 1.1, the oil temperature of microreactor is controlled to be 10~15 ℃ in the reaction process, the residence time of material in the microreactor is 0.27min in the ...

Embodiment 2

[0035] A kind of preparation method of chloroacetaldehyde oxime, take acetaldehyde oxime solution and chlorine gas as raw material, prepare chloroacetaldehyde oxime with microreactor as reaction device, comprise the following steps:

[0036] (1) Preparation of acetaldehyde oxime solution: 120 g of acetaldehyde oxime (mass concentration ≥ 99.0%, 2.0 mol), 175 g of methanol and 5 g of water were uniformly mixed to obtain an acetaldehyde oxime solution.

[0037] (2) Select a microreactor with five reaction templates. The acetaldehyde oxime solution prepared in the step (1) is injected in the microreactor with the speed of 300g / h by metering pump, feeds chlorine into microreactor with the speed of 156g / h simultaneously and reacts, in the reaction process Control the mol ratio of acetaldehyde oxime and chlorine to be 1: 1.1, the oil temperature of microreactor is controlled to be 10~15 ℃ in the reaction process, the residence time of material in the microreactor is 0.45min in the r...

Embodiment 3

[0040] A kind of preparation method of chloroacetaldehyde oxime, take acetaldehyde oxime solution and chlorine gas as raw material, prepare chloroacetaldehyde oxime with microreactor as reaction device, comprise the following steps:

[0041](1) Preparation of acetaldehyde oxime solution: 120 g of acetaldehyde oxime (mass concentration ≥ 99.0%, 2.0 mol), 175 g of methanol and 5 g of water were mixed uniformly to obtain an acetaldehyde oxime solution.

[0042] (2) Select a microreactor with three reaction templates. The acetaldehyde oxime solution prepared in the step (1) is injected in the microreactor with the speed of 300g / h by metering pump, feeds chlorine into microreactor with the speed of 156g / h simultaneously and reacts, in the reaction process Control the mol ratio of acetaldehyde oxime and chlorine to be 1: 1.1, the oil temperature of microreactor is controlled to be 15~20 ℃ in the reaction process, the residence time of material in the microreactor is 0.27min in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com