Preparation method of phosphogypsum roadbed material based on high temperature activation and hydraulic hardness improvement

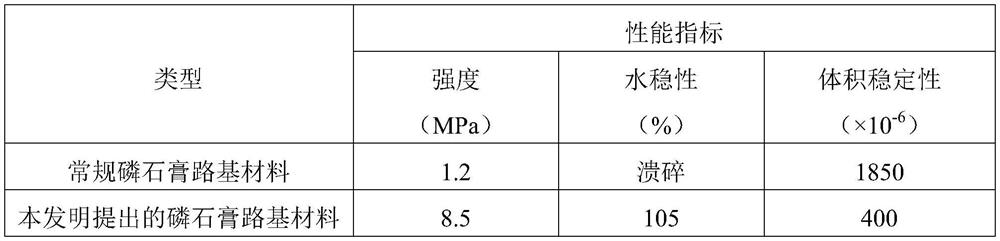

A roadbed material and high-temperature activation technology, which is applied in the field of preparation of phosphogypsum roadbed materials, can solve the problems of not utilizing and exerting the bonding strength of phosphogypsum roadbed materials, lack of volume stability of phosphogypsum roadbed materials, endangering engineering quality and traffic safety, and achieving Guaranteed volume stability, improved strength and water stability, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment technical scheme of the present invention is described in detail as follows:

[0025] A method for preparing a phosphogypsum roadbed material based on high-temperature activation and improved hydraulicity proposed by the present invention comprises the following steps:

[0026](1) Calcining phosphogypsum with a free moisture content of 7%-20% in an environment of 100°C-1000°C to obtain high-temperature products; high-temperature products include hemihydrate gypsum, type III anhydrite and type II anhydrite Any one or more of them; wherein, the calcination temperature for generating the hemihydrate gypsum is between 100°C and 170°C, the calcination temperature for generating the Type III anhydrite is between 170°C and 350°C, and the calcination temperature for generating the The calcining temperature of type II anhydrite is between 350°C and 1000°C. Wherein, the mass percentages of the hemihydrate gypsum, type III anhydrite and type I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com