Large-mesopore tungsten oxide hydrogen sulfide sensitive material with high specific area and preparation method thereof

A technology of high specific surface area and sensitive material, applied in the field of high specific surface area and large mesoporous tungsten oxide hydrogen sulfide sensitive material and its preparation, can solve the problems of low detection limit and high sensitivity, achieve low detection limit, high sensitivity, and speed up response recovery effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

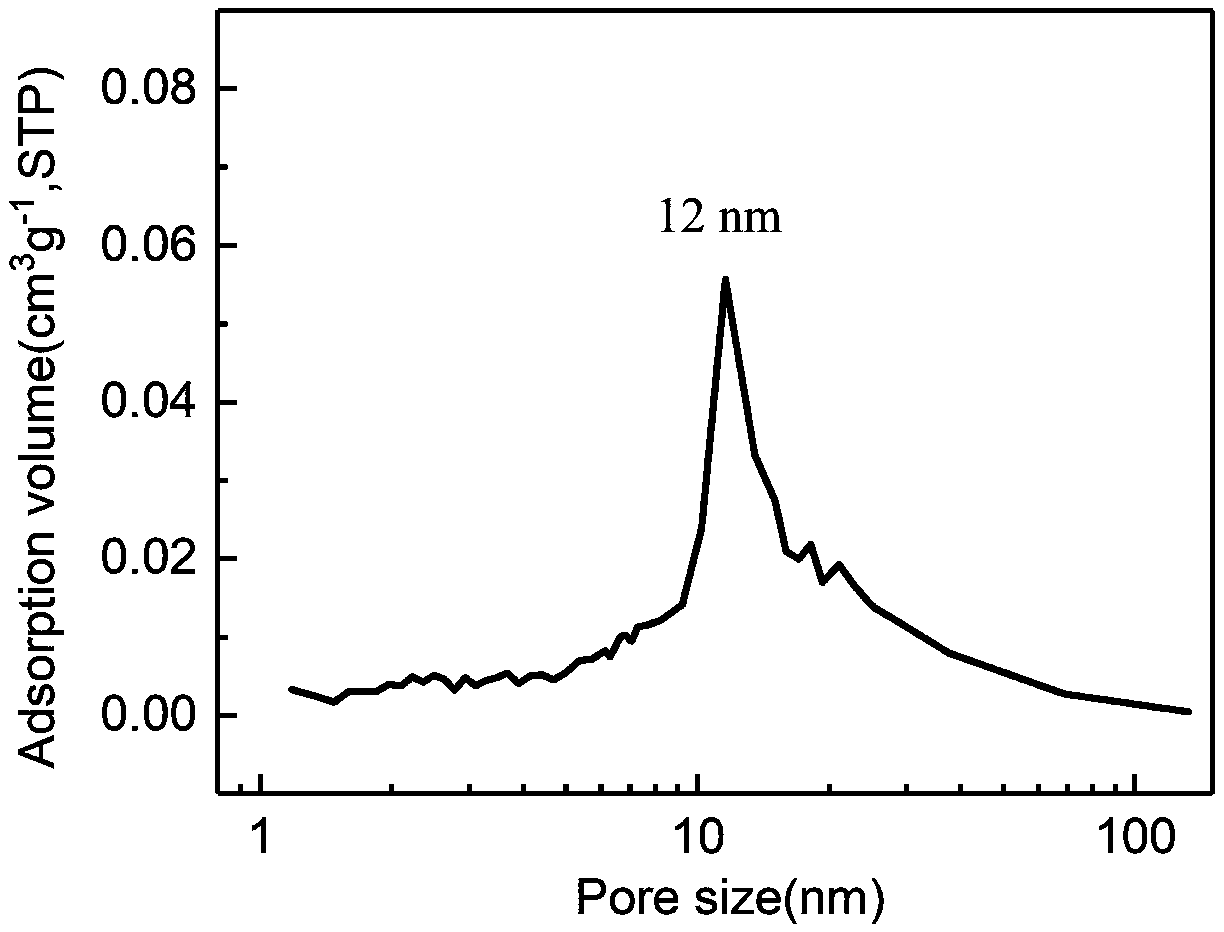

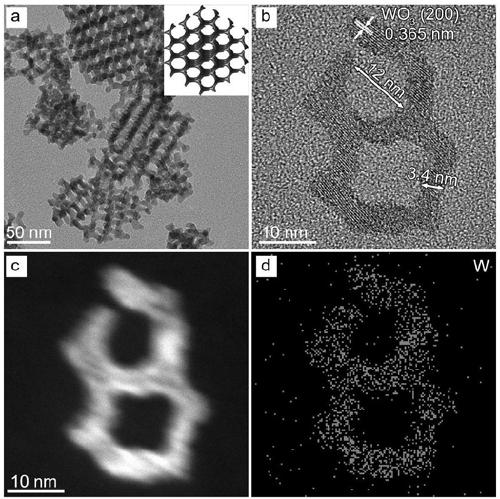

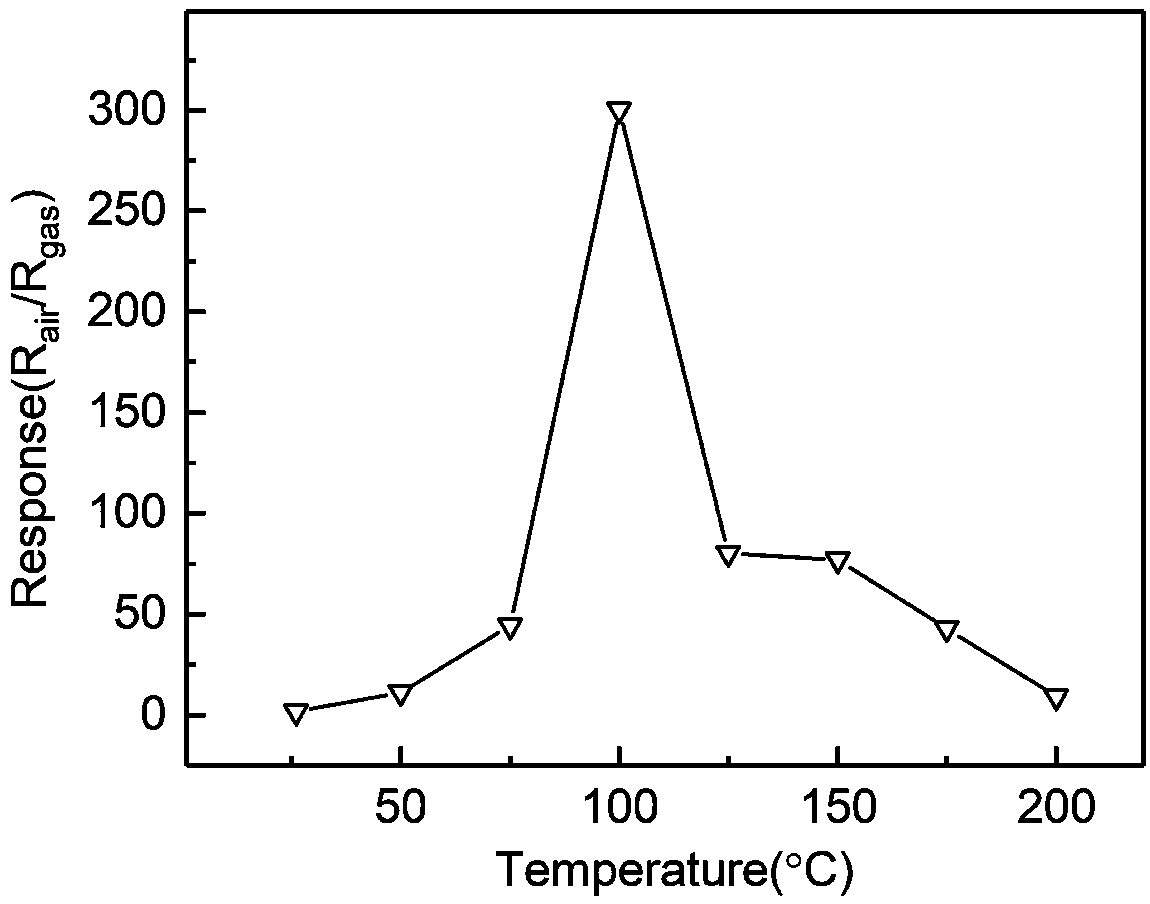

[0021] The invention relates to a sensitive material for detecting trace concentration hydrogen sulfide and a preparation method thereof, belonging to the technical field of sensitive materials. The high specific surface area and large mesoporous tungsten oxide hydrogen sulfide sensitive material is composed of helical nanowires of tungsten oxide, which are periodically arranged in cubes. The diameter of the nanowires is about 3-7nm, with uniform large mesoporous pores of about 12nm, and the specific surface area can reach up to 163m 2 / g. The gas sensor made of this material has a sensitivity of 1ppm hydrogen sulfide (the ratio of the resistance of the gas sensor in the measured gas to the resistance of the gas sensor in the air) of 300 at the optimum working temperature of 100 °C, and the lower detection limit is lower than 2ppb (sensitivity up to 2.28). The response value of the gas sensor to 1ppm formaldehyde, acetone, ethanol, toluene, benzene, p-xylene, ammonia, and car...

Embodiment 1

[0029] Mix 72g of surfactant P123, 2592ml of deionized water and 120ml of 37wt% hydrochloric acid at 35°C, stir for 1-12h until the surfactant is completely dissolved and dispersed evenly, then add 89ml of n-butanol, stir for 2h and then add 166ml tetraethyl orthosilicate TEOS, stirred in a water bath for 24 hours, then transferred the solid particles and the reaction solution to a polytetrafluoroethylene lining, followed by a hydrothermal reaction at 40°C for 24 hours, cooled naturally to room temperature, and washed with deionized water until neutral , Dry overnight at 70°C to obtain mesoporous silica containing surfactant, and remove P123 by calcining at 550°C in air for 6h to obtain white powder, namely mesoporous silica without surfactant.

[0030] Completely dissolve 0.48g of silicotungstic acid in 10ml of absolute ethanol to obtain an absolute ethanol solution of silicotungstic acid, add 2g of the above-mentioned treated mesoporous silica to the solution as a hard templa...

Embodiment 2

[0034] Mix 72g of surfactant P123, 2592ml of deionized water and 120ml of 37wt% hydrochloric acid at 35°C, stir for 1-12h until the surfactant is completely dissolved and dispersed evenly, then add 89ml of n-butanol, stir for 2h and then add 166ml tetraethyl orthosilicate TEOS, stirred in a water bath for 24 hours, then transferred the solid particles and the reaction solution to a polytetrafluoroethylene lining, followed by a hydrothermal reaction at 40°C for 24 hours, cooled naturally to room temperature, and washed with deionized water until neutral , Dry overnight at 70°C to obtain mesoporous silica containing surfactant, and remove P123 by calcining at 550°C in air for 6h to obtain white powder, namely mesoporous silica without surfactant.

[0035] Completely dissolve 0.96g of silicotungstic acid in 10ml of absolute ethanol to obtain an absolute ethanol solution of silicotungstic acid, add 2g of the above-mentioned treated mesoporous silica to the solution as a hard templa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com