Hollow molecular sieve of microsphere structure and preparing method of sieve

A molecular sieve and hollow technology, applied in the field of porous materials, can solve the problems of reducing the adsorption and separation efficiency of porous materials for gas molecules, the inability of the pore surface to function, and the increase of gas flow resistance. The effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

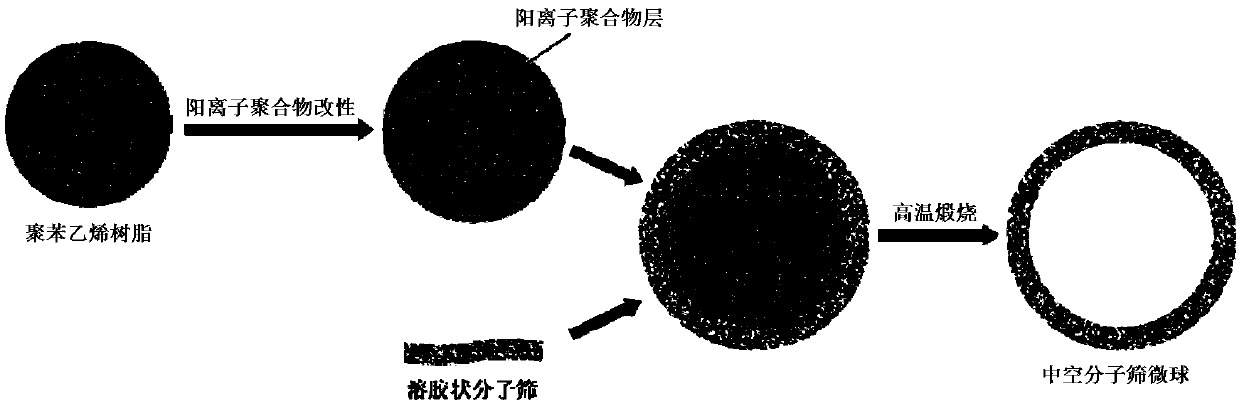

Embodiment 1

[0028] Add tetraethyl orthosilicate, tetraethylammonium hydroxide aqueous solution (TEA), aluminum isopropoxide, sodium hydroxide and deionized water in a ratio of 50:9:1:0.7:500 to a thermometer, stir device and condenser in a three-necked flask. Then place the three-necked flask in an oil bath, and react for 200 h while maintaining a temperature of 100° C. and a stirring state of 300 rpm to obtain a sol-like molecular sieve. The reacted solution was filtered to remove the mother liquor, and then the molecular sieve was redissolved in deionized water, and an ammonia solution with a concentration of 0.1 mol / L was added thereto to adjust the pH to 9.5. Subsequently, 3 g of polystyrene resin, 300 mL of deionized water and 3 g of cationic polymer were added to another three-necked flask equipped with a thermometer, a stirrer and a condenser tube, and then an ammonia solution with a concentration of 0.1 mol / L was added to adjust the pH to 9.0. The above-mentioned three-necked fl...

Embodiment 2

[0032] Add tetraethyl orthosilicate, tetraethylammonium hydroxide aqueous solution (TEA), aluminum isopropoxide, sodium hydroxide and deionized water in a ratio of 60:10:1:1:600 to a thermometer, stir device and condenser in a three-necked flask. . Then place the three-necked flask in an oil bath, and react for 190 h while maintaining a temperature of 90° C. and stirring at 400 rpm to obtain a sol-like molecular sieve. The reacted solution was filtered to remove the mother liquor, and then the molecular sieve was redissolved in deionized water, and an ammonia solution with a concentration of 0.1 mol / L was added thereto to adjust the pH to 9.5. Subsequently, 3 g of polystyrene resin, 300 mL of deionized water and 3 g of cationic polymer were added to another three-necked flask equipped with a thermometer, a stirrer and a condenser tube, and then an ammonia solution with a concentration of 0.1 mol / L was added to adjust the pH to 9.0. The above-mentioned three-necked flask f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com