Limiting device for steel pipes in automatic assembly line of steel pipes

A limit device and assembly line technology, applied in the mechanical field, can solve the problems of steel pipe end damage, steel pipe inapplicability, poor applicability, etc., and achieve the effect of high applicability, high practical value, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

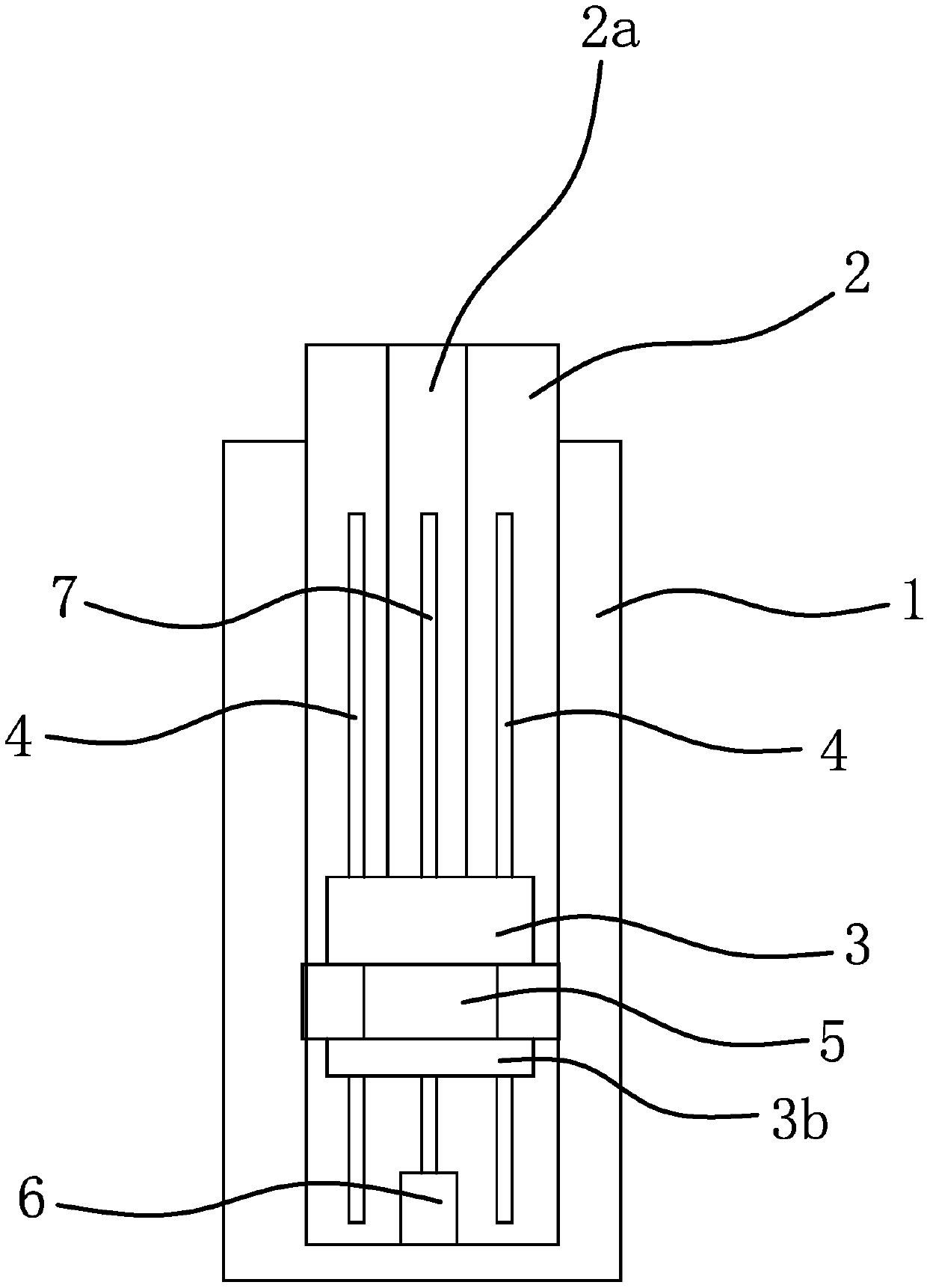

[0032] Such as figure 1 As shown, the automatic assembly line includes a frame 1, on which there is a workbench 2 for placing steel pipes, and on the workbench 2 is a concave positioning groove 2a.

[0033] Such as figure 1 and figure 2 and image 3 As shown, the limit device of the steel pipe in the automatic assembly line of the steel pipe is set at the workbench 2. The limit device includes a slider 3, a guide rod 4, a limit block 5 and a driving part. The above guide rod 4 is in the shape of a long rod , the slider 3 is connected to the guide rod 4 , the driver is fixedly connected to the workbench 2 and the driver is connected to the slider 3 , and the limiting block 5 is fixed to the upper part of the slider 3 .

[0034] The driving member includes a motor 6 and a screw rod 7 , the screw rod 7 is axially fixedly connected to the workbench 2 , and the screw rod 7 is screwed to the lower part of the slider 3 .

[0035] The lower part of the slider 3 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com