Interference rainbow film solution formula, interference film and preparation method of interference film

An interference film and rainbow film technology, applied in the direction of coating, can solve the problems of high cost, complex process, high dependence on raw materials, etc., and achieve the effects of low cost, simple method and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

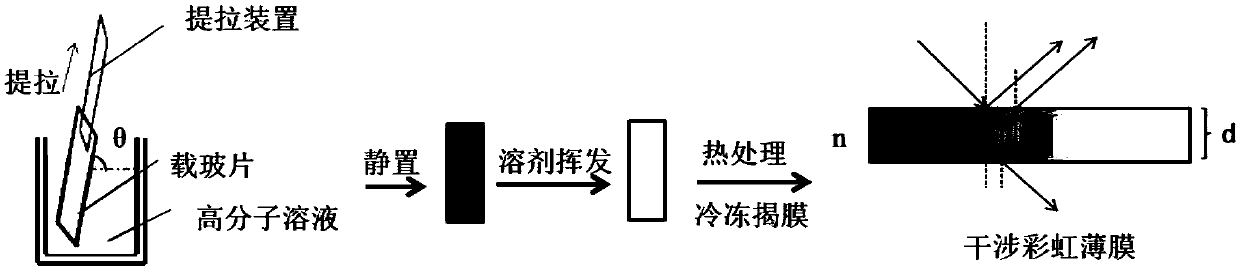

Method used

Image

Examples

Embodiment 1

[0047] Soak the slides in 2% hydrochloric acid for several hours to wash away the hydrochloric acid. Then put it in the detergent solution and soak it overnight, rinse it with water, soak it in distilled water or dry it and put it in a box for later use. According to parts by weight, take 100 parts of polylactic acid, 30 parts of polybutylene adipate terephthalate, and 20 parts of polymethyl methacrylate in 40,000 parts of dichloromethane, 6,000 parts of chloroform, and 4,000 parts of ethanol. part of the mixed solution. Pour the prepared solution into the container, use a lifting device, insert the cleaned glass slide into the solution at θ=90 degrees, and immediately pull the glass slide to the liquid surface at a speed of 100 mm / min and θ=90 degrees As mentioned above, the surface of the glass slide is coated with a certain thickness of polymer coating, and it is left to stand under natural conditions until the solution is completely evaporated. The obtained glass slide l...

Embodiment 2

[0049]Soak the slides in 2% hydrochloric acid for several hours to wash away the hydrochloric acid. Then put it in the detergent solution and soak it overnight, rinse it with water, soak it in distilled water or dry it and put it in a box for later use. According to parts by weight, 100 parts of polylactic acid and 10 parts of polybutylene adipate terephthalate were weighed and dissolved in 80000 parts of dichloromethane. Pour the prepared solution into a glass beaker, and use a pulling device to insert the cleaned glass slide into the solution at θ=80 degrees, and immediately pull the glass slide to the liquid surface at a speed of 400 mm / min and θ=80 degrees As above, the surface of the glass slide is coated with a certain thickness of polymer coating, and it is left to stand under natural conditions until the solution is completely evaporated, and the above pulling operation is repeated once. Gained slide glass that is loaded with interference film is put into constant tem...

Embodiment 3

[0051] Soak the slides in 2% hydrochloric acid for several hours to wash away the hydrochloric acid. Then put it in the detergent solution and soak it overnight, rinse it with water, soak it in distilled water or dry it and put it in a box for later use. Weigh 100 parts of polylactic acid, 20 parts of polybutylene adipate terephthalate, 30 parts of polymethyl methacrylate, 20 parts of acrylonitrile-butadiene-styrene copolymer, poly 10 parts of styrene, 10 parts of styrene-butadiene-styrene block copolymer, 20 parts of styrene-isoprene-styrene block copolymer, dissolved in 50,000 parts of dichloromethane, 10,000 parts of chloroform , 5,000 parts of acetone, and 8,000 parts of ethanol in a mixed solution. Pour the prepared solution into a glass beaker, and use a lifting device to insert the cleaned glass slide into the solution at θ=45 degrees, and immediately pull the glass slide to the liquid surface at a speed of 300 mm / min and θ=45 degrees As mentioned above, the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com