Forming device of microstructure on inner wall of tube

A technology of microstructure and inner wall of the tube, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problem of little research on manufacturing, and achieve the effect of good performance and rapid positioning and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

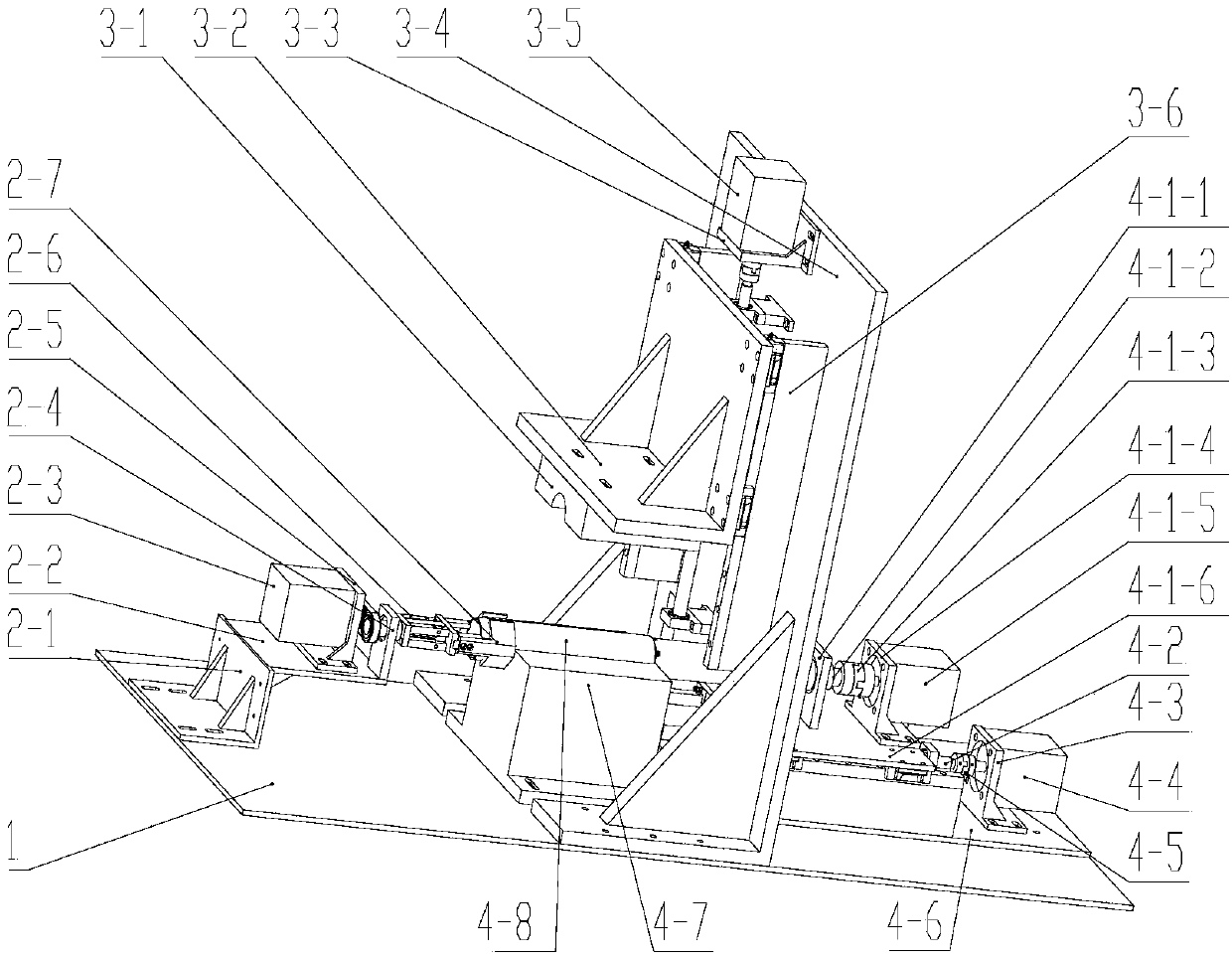

[0037] like Figure 1-19 As shown, the embodiment of the present invention is provided with a large bottom plate 1, a clamping and rotating mechanism, a pressing mechanism and a stamping and forming assembly; the clamping and rotating mechanism, a pressing mechanism and a stamping and forming assembly are fixed on the large bottom plate 1;

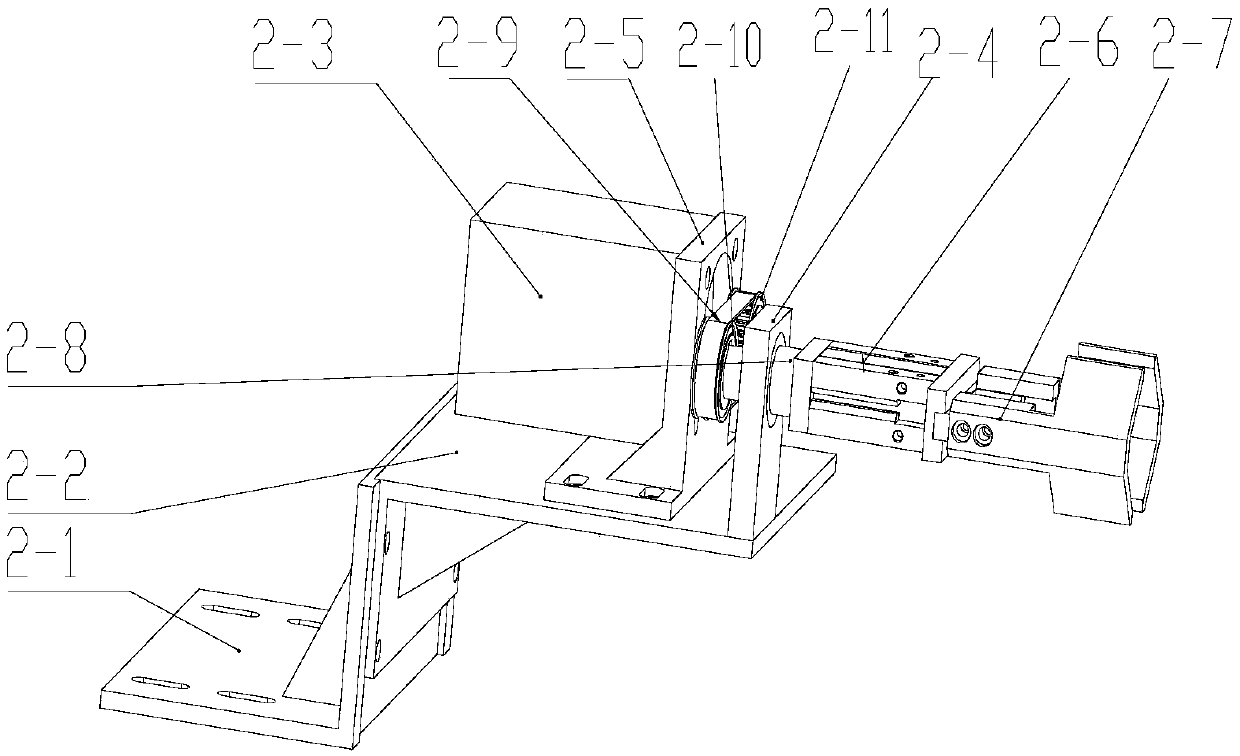

[0038] The clamping and rotating mechanism is provided with a height support seat 2-1, a first mounting seat 2-2, a first servo motor 2-3, a first bearing seat 2-4, a first motor mounting seat 2-5, a clip Tight cylinder 2-6, air claw 2-7, cylinder rotating shaft 2-8, belt 2-9, the first pulley 2-10, the second pulley 2-11;

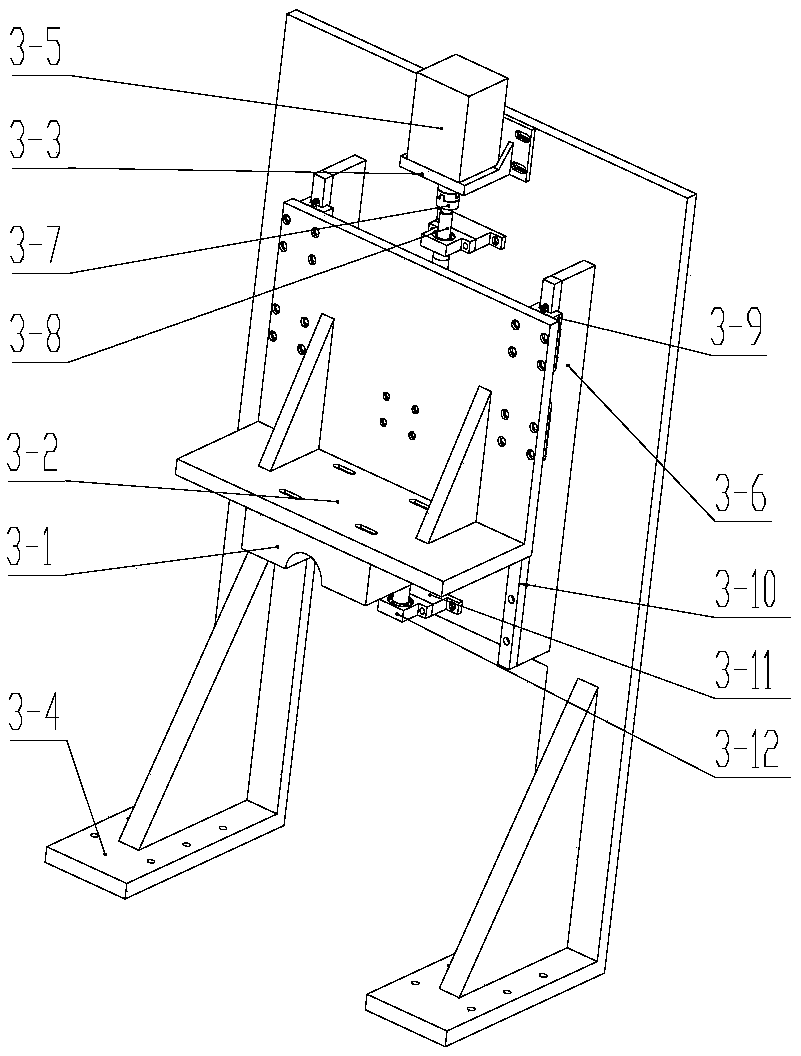

[0039] The pressing mechanism is provided with a positioning upper cover 3-1, an upper cover mounting base 3-2, a second motor mounting base 3-3, a second mounting base 3-4, a second servo motor 3-5, a first pad High seat 3-6, first coupling 3-7, first screw rod 3-8, first slider 3-9, first slide rail 3-10, bearing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com