Smart internet car paint quickly repairing assembly line

An Internet and assembly line technology, applied to coatings, grinding machines, special surfaces, etc., can solve problems such as unrepairable process information acquisition, errors, and operator interference, and achieve the effect of convenient material preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

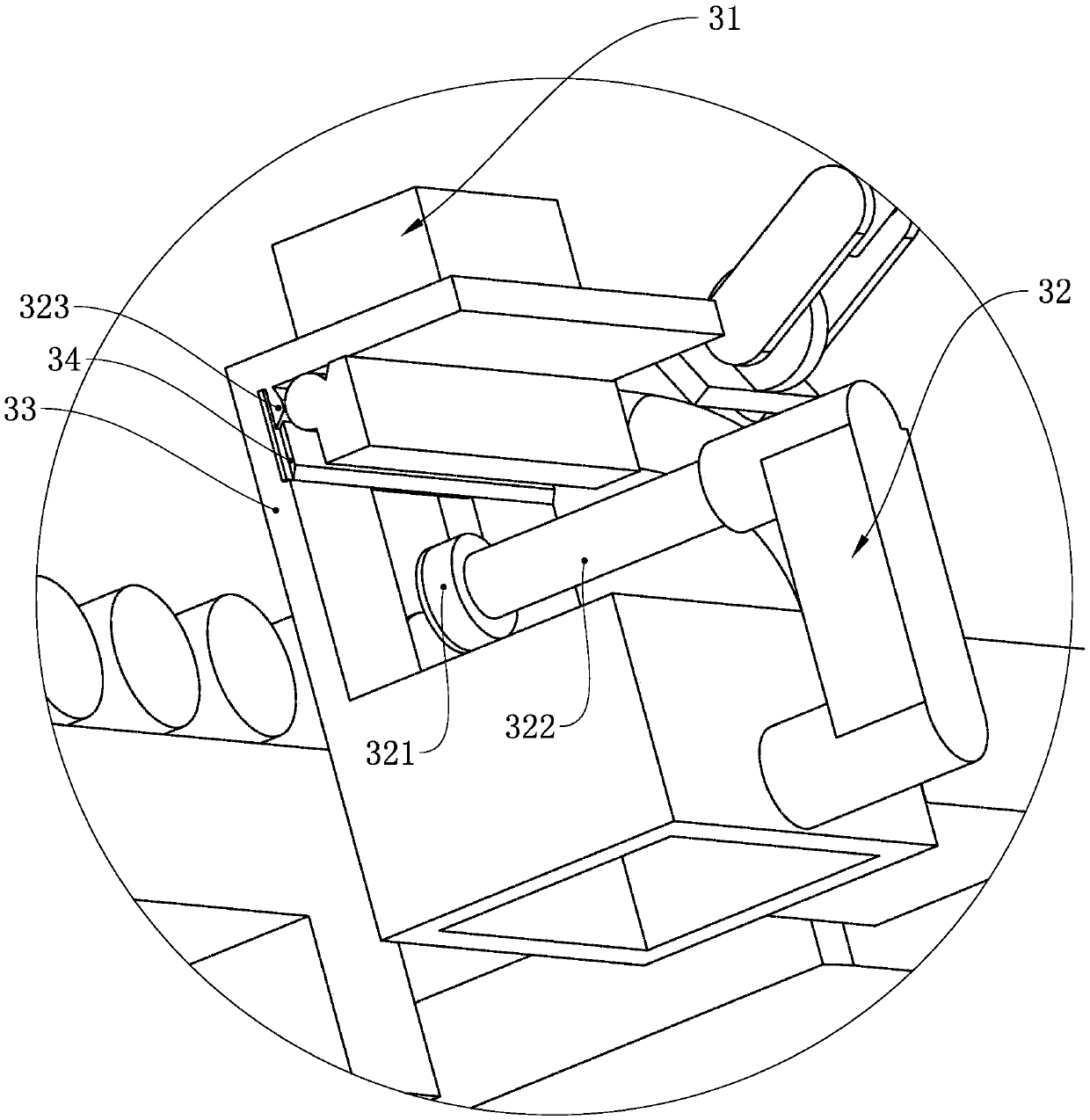

[0054] Such as Figure 1-Figure 2As shown, an intelligent Internet car paint quick repair assembly line includes a transmission mechanism, the transmission mechanism includes a conveyor belt 1 driven by a power source, and a transmission carrier body 2 is installed on the conveyor belt, and the transmission carrier body 2 is used for Carrying the vehicle to be repaired, one side of the main body of the transmission is provided with an information area 27 for pasting labels; wherein, the conveyor belt 1 adopts a roller sprocket transmission method, and when the conveyor belt is delivered in place, it stops. In addition, the conveyor belt is set as a ground The pit form makes it easy for the vehicle to reach the main body of the transmission. At the same time, the entire assembly line is arranged in a circular track style. The vehicle can be repaired at a certain place, and it can be offline for acceptance after detouring to a certain place, which can improve the utilization rate...

Embodiment 2

[0061] Such as Figure 5 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: this embodiment is provided with a suction hole mechanical arm 5 in the sheet metal operation section, and a grinding mechanical arm 6 is provided in the grinding operation section, wherein the suction pit The left side of the rectangular mounting plate on the top of the pit robot arm 5 and the grinding robot arm 6 is respectively equipped with a pit suction device 51 and a grinder 61, and the right side is respectively equipped with a pit suction miniature camera 52 and a polishing miniature camera 53, and the manipulator can be operated manually to be repaired. The vehicle is subjected to suction pit and grinding treatment; the intermediate coating operation section and the painting operation section are provided with a painting robot arm 7, and the top mounting plate of the painting robot arm 7 is disc-shaped, and the disc is divided into...

Embodiment 3

[0063] Such as Figure 6 As shown, isolation room 8 is arranged in intermediate coating operation section and painting operation section. The isolation room is made of transparent glass material. The isolation can also ensure the automatic control switch of the isolation room. The prior art electrostatic precipitator is installed inside the isolation room to clean the internal environment of the isolation room before work and the dust generated during the grinding process at any time to ensure the cleanliness of the isolation room environment. Dust: The external control platform adopts the control system design of the existing technology, and can implement the internal mechanism functions of the isolation room through manual operation.

[0064] Example of use

[0065] The owner of the car, Mr. Sun, was repaired due to a car rear-end collision. The maintenance personnel quickly assessed the damage of the vehicle, and reported the information of the vehicle to be repaired (vehi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com