A method for classifying and purifying weathered potassium feldspar ore

A technology of potassium feldspar and potassium feldspar powder, which is applied in the field of purification of weathered potassium feldspar minerals, which can solve the problem that feldspar and gangue minerals cannot be effectively separated, and high-quality feldspar powder and feldspar mineral utilization cannot be produced. Low efficiency and other problems, to achieve good flotation effect, expand the cut-off grade, and increase the added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

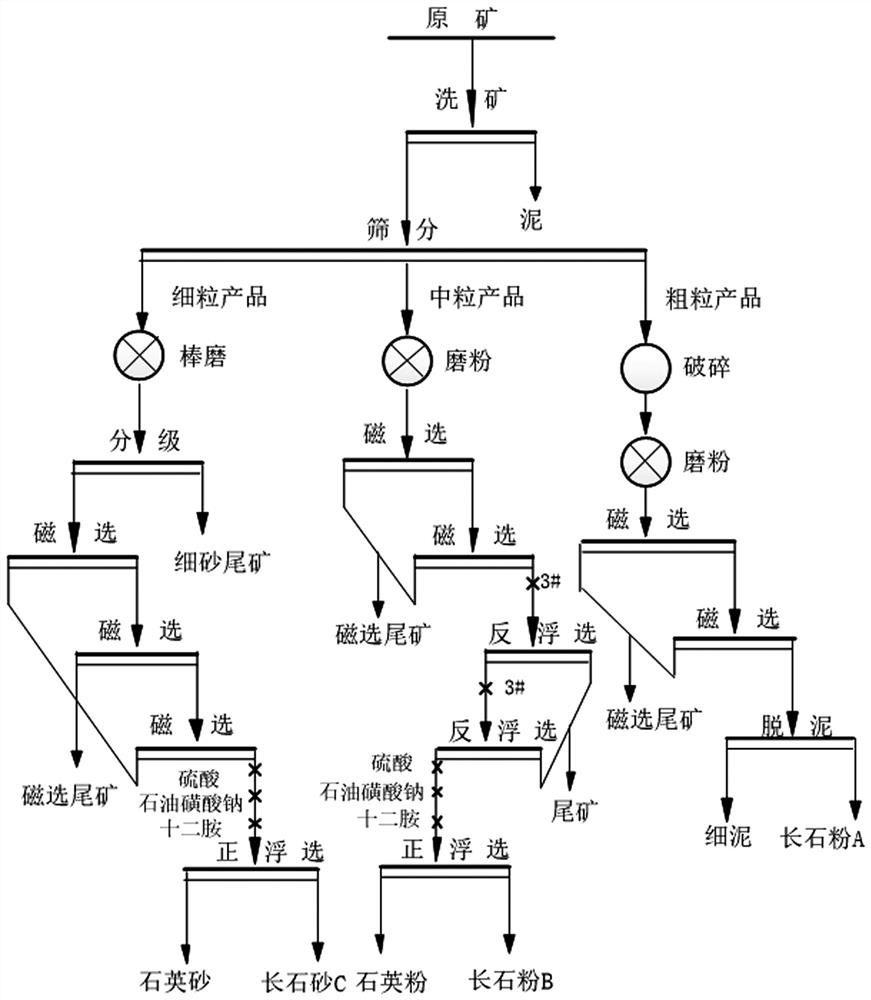

Method used

Image

Examples

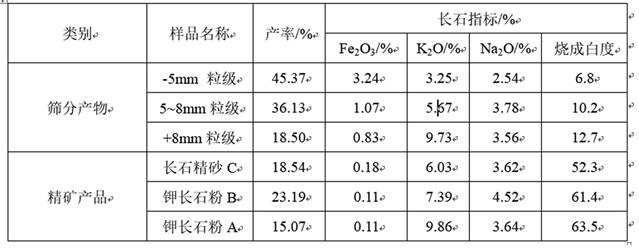

Embodiment 1

[0028] For the weathered potassium feldspar mine in a certain place in Guangxi, the mineral structure is loose-semi-loose, mainly light gray, taupe or slightly fleshy red, and the feldspar has been partially weathered into white kaolin or sandy soil, and biotite-like dark minerals and Brown iron spots, potassium feldspar grains are mainly distributed between 3~20mm.

[0029] The specific process steps of mineral purification and impurity removal are as follows:

[0030] (1) After the raw ore is washed, it is screened into three grades of +8mm, 5~8mm, and -5mm, where + means greater than, and - means less than;

[0031] (2) -5mm fine-grained minerals adopt the following steps:

[0032] Rod mill, the particle size of the rod mill product is controlled below 0.6mm, and then hydraulic classification is carried out to obtain classified sand settling and classified fine sand (tailings);

[0033] Classified sand settling is used for three magnetic separations. The magnetic separati...

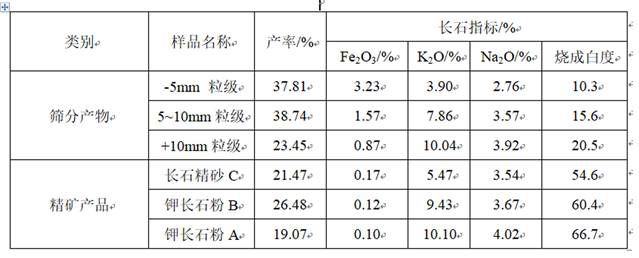

Embodiment 2

[0044] The weathered potassium feldspar mine in a certain place in Anhui has a loose-semi-consolidated sandy structure. The ore is a regular striped feldspar, light fleshy red, semi-euhedral plate columnar, and the potassium feldspar grains are mainly distributed between 5 and 30mm.

[0045] The specific process conditions for mineral purification and impurity removal are as follows:

[0046] (1) After the raw ore is washed, it is screened into three grades of +10mm, 5~10mm, and -5mm;

[0047](2) -5mm minerals are purified through the process of "rod milling-classification-medium magnetic separation-strong magnetic separation-strong magnetic separation-positive flotation", the particle size of the rod mill product is controlled below 0.6mm, and the magnetic field strength of the third magnetic separation is 5000GS , 10000GS, 12000GS, positive flotation using H 2 SO 4 Adjust the pH to 2~3, the dosage of collector sodium petroleum sulfonate is 2.4kg / t, and the dosage of dodecy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com