Method for continuously producing D-lactate

A lactic acid ester and lactic acid technology, applied in the field of continuous production of D-lactate, can solve the problems of high impurity content, high corrosion resistance requirements, and difficult wastewater treatment, so as to achieve good product quality, reduce corrosion, reduce The effect of wastewater volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

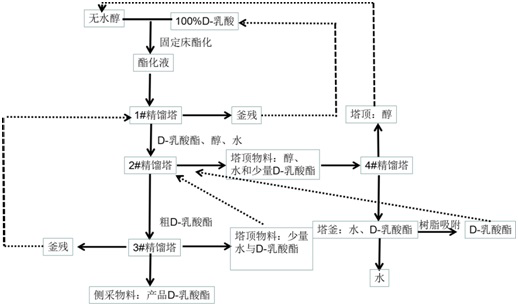

[0035] Such as figure 1 Shown, a kind of method of continuous production D-lactate, specifically:

[0036] 1. Use cation exchange resin to fill the guard column, and use macroporous resin to fill the fixed bed, then connect the guard column and the fixed bed.

[0037] The filling capacity of cation exchange resin in the guard column is 4.2m 3 ; The filling capacity of the macroporous resin in the fixed bed is 17.18m 3 .

[0038] The manufacturer of the cation exchange resin is Jiangsu Suqing Water Treatment Engineering Group Co., Ltd., and the model is SQ716.

[0039] The macroporous resin is acid macroporous resin D113, the manufacturer is Langfang Qingteng Thermal Insulation Building Materials Co., Ltd., and the particle size is 0.315-1.25mm.

[0040] The function of the guard column is to remove metal cations in the reaction materials and prolong the single-pass service life of the resin in the fixed bed. During the reaction process, the reactant lactic acid is mixed w...

Embodiment 2

[0057] Such as figure 1 Shown, a kind of method of continuous production D-lactate, specifically:

[0058] 1. Use cation exchange resin to fill the guard column, and use macroporous resin to fill the fixed bed, then connect the guard column and the fixed bed;

[0059] The filling capacity of cation exchange resin in the guard column is 4.2m 3 ; The filling capacity of the macroporous resin in the fixed bed is 17.18m 3 .

[0060] The manufacturer of the cation exchange resin is Ningbo Zhengguang Resin Co., Ltd., the model is C-180, and the macroporous resin is acidic macroporous resin HND-12, and the manufacturer is Jiangsu Nanda Catalyst Research Center, with a particle size of 0.315-1.25mm .

[0061] The function of the guard column is to remove metal cations in the reaction materials and prolong the single-pass service life of the resin in the fixed bed. During the reaction process, the reactant lactic acid is mixed with methanol and then enters the guard column to remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com