Impurity removing system for Chinese art paper black liquor

A technology of black liquor and rice paper, which is applied in the field of impurity removal system of rice paper black liquor, can solve problems affecting solid material processing, affecting heating effect, hindering the normal operation of black liquor processing system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings.

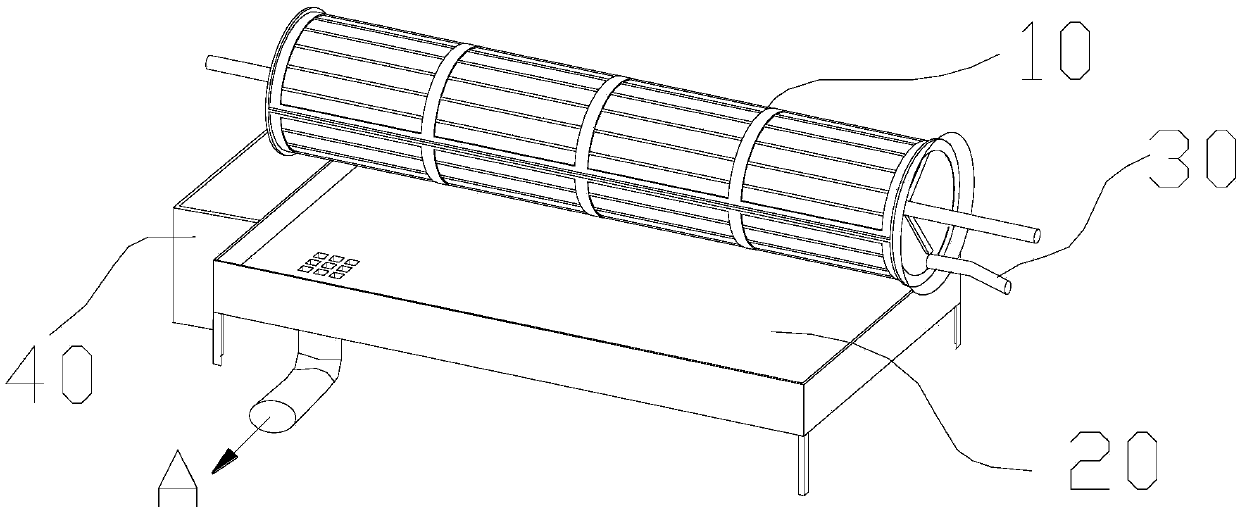

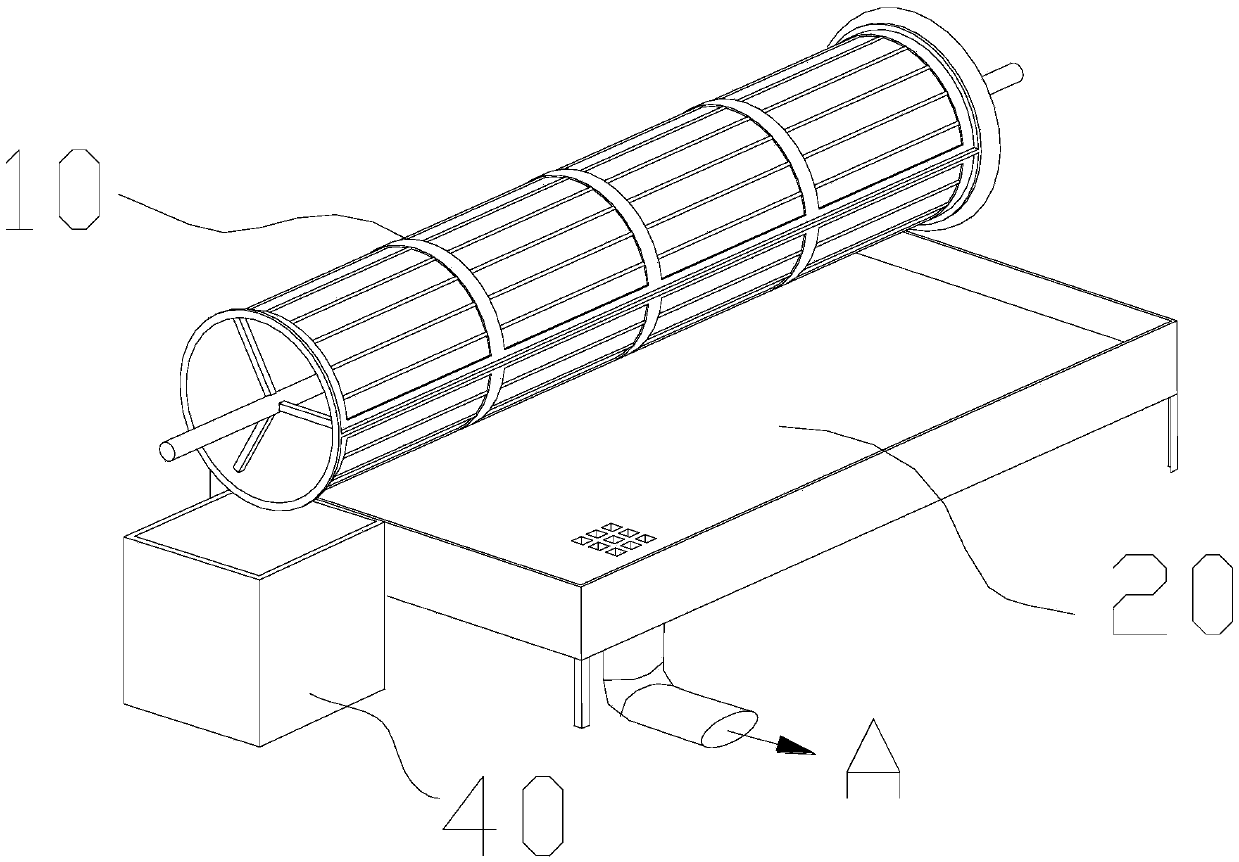

[0011] A system for removing impurities from rice paper black liquor, including a filter unit 10, the filter unit 10 includes a tubular frame and a filter screen attached to the frame, the filter unit 10 is arranged above the filtrate pool 20, and the black liquor enters the liquid The pipe 30 communicates with the lumen of the filter unit 10 , and the filtrate pool 20 is connected with the black liquor treatment system A.

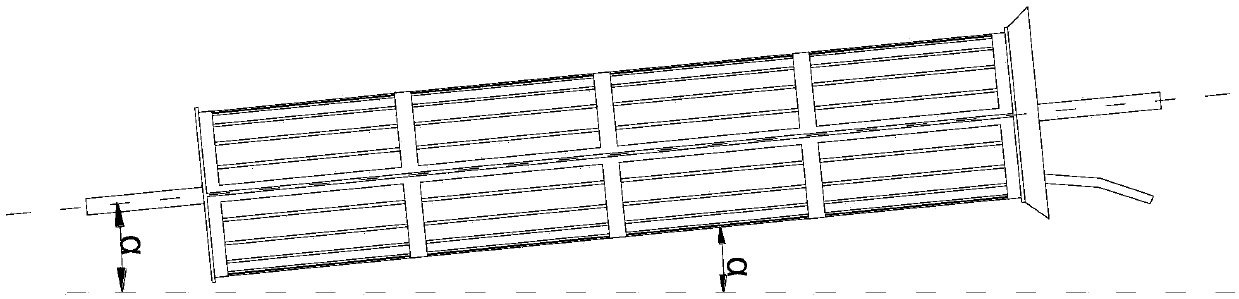

[0012] As a preferred solution, the bottom of the nozzle at one end of the filter unit 10 is lower than the bottom of the nozzle at the other end, and the higher end of the nozzle bottom is the liquid inlet end. The bottom of one end of the filter unit is high and the bottom of the other end is low. There are two ways. One is that the tubular frame of the filter unit is a straight tube, and the axis and the horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com