A three-dimensional multilayer structure surface enhanced Raman substrate and its preparation method

A technology of structured surface and Raman substrate, which is applied in the field of molecular recognition to achieve the effect of good controllability and rich structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

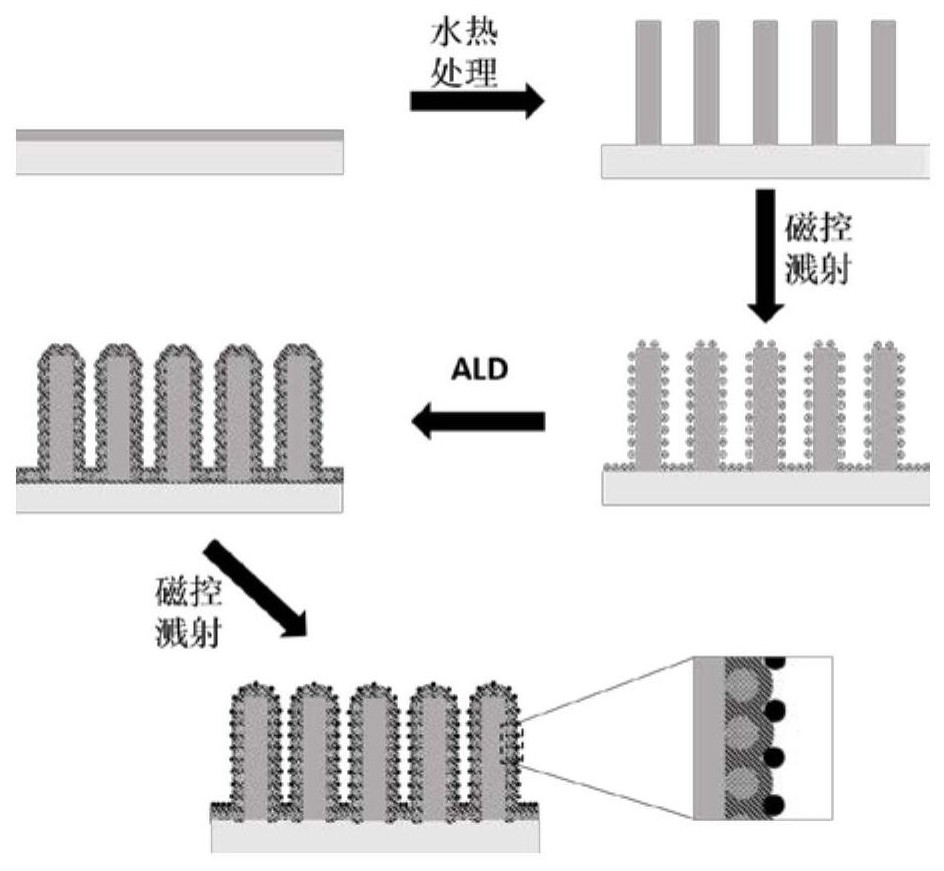

[0055] The present invention also provides a method for preparing a surface-enhanced Raman substrate with a three-dimensional multilayer structure, comprising the following steps:

[0056] Step 1, growing the ZnO seed layer:

[0057] The substrate was ultrasonically cleaned by acetone, ethanol, and deionized water for 10 minutes, and a ZnO seed layer was grown on the surface of the substrate by magnetron sputtering. The radio frequency power was 80W, the flow rate of argon gas was 40 sccm, and the growth time was 10 minutes;

[0058] Step 2, preparing ZnO nanorod arrays:

[0059] Zn(NO 3 ) 2 ·6H 2 O solution and C 6 h 12 N 4 The solutions are mixed, and the mixed solution is placed in a reaction kettle, and then the substrate for growing the ZnO seed layer is placed in the reaction kettle for reaction. The reaction temperature is 95° C. and the time is 3 hours. After the reaction is completed, the substrate is taken out. Wash it with deionized water and dry it to get a ...

Embodiment 1

[0070] 1. Grow ZnO seed layer: 1*1cm 2 The ITO substrate was ultrasonically cleaned with acetone, ethanol, and deionized water for 10 minutes, respectively. A ZnO thin film with a thickness of 15 nm was grown on the surface of the substrate by magnetron sputtering, the radio frequency power was 80 W, the flow rate of argon gas was 40 sccm, and the growth time was 10 min.

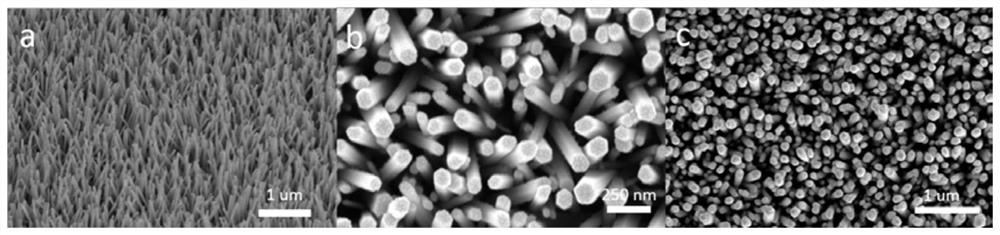

[0071] 2. Preparation of ZnO nanorod arrays: 0.025mol / L of Zn(NO 3 ) 2 ·6H 2 O (2.9749g) and 0.025mol / L of C 6 h 12 N 4 (1.419g) each took 10mL, mixed the above two solutions, and put them in the reaction kettle. Then, put the ITO conductive glass substrate coated with the seed layer solution vertically into it, react at 95°C for 3 hours, take out the substrate, clean it with deionized water, and dry it to get a neat substrate. ZnO nanorod arrays, see figure 2 a. From figure 2 a It can be seen that the nanorods grow perpendicular to the substrate and are uniformly arranged, with a diameter of 100...

Embodiment 2

[0079] 1. Grow ZnO seed layer: 1*1cm 2 The ITO substrate was ultrasonically cleaned with acetone, ethanol, and deionized water for 10 minutes, respectively. A ZnO thin film with a thickness of 15 nm was grown on the surface of the substrate by magnetron sputtering, the radio frequency power was 80 W, the flow rate of argon gas was 40 sccm, and the growth time was 10 min.

[0080] 2. Preparation of ZnO nanorod arrays: 0.025mol / L of Zn(NO 3 ) 2 ·6H 2 O (2.9749g) and 0.025mol / L of C 6 h 12 N 4(1.419g) each took 10mL, mixed the above two solutions, and put them in the reaction kettle. Then, put the ITO conductive glass substrate coated with the seed layer solution vertically into it, react at 95°C for 3 hours, take out the substrate, clean it with deionized water, and dry it to get a neat substrate. The ZnO nanorod array, the nanorods grow perpendicular to the substrate, are uniformly arranged, have a diameter of 100nm, and a length of 1μm.

[0081] 3. Preparation of ZnO@A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com