Structural steel-UHPC (Ultra High Performance Concrete) composition board longitudinal rib staggered arrangement construction and construction method thereof

A technology with interlaced longitudinal ribs and construction methods, which is applied to bridge parts, erection/assembly bridges, bridges, etc., can solve the problems of easy cracking of bridge decks and large axial force of beam sections, and achieves small workload, small pouring amount, and reduced The effect of bridge construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

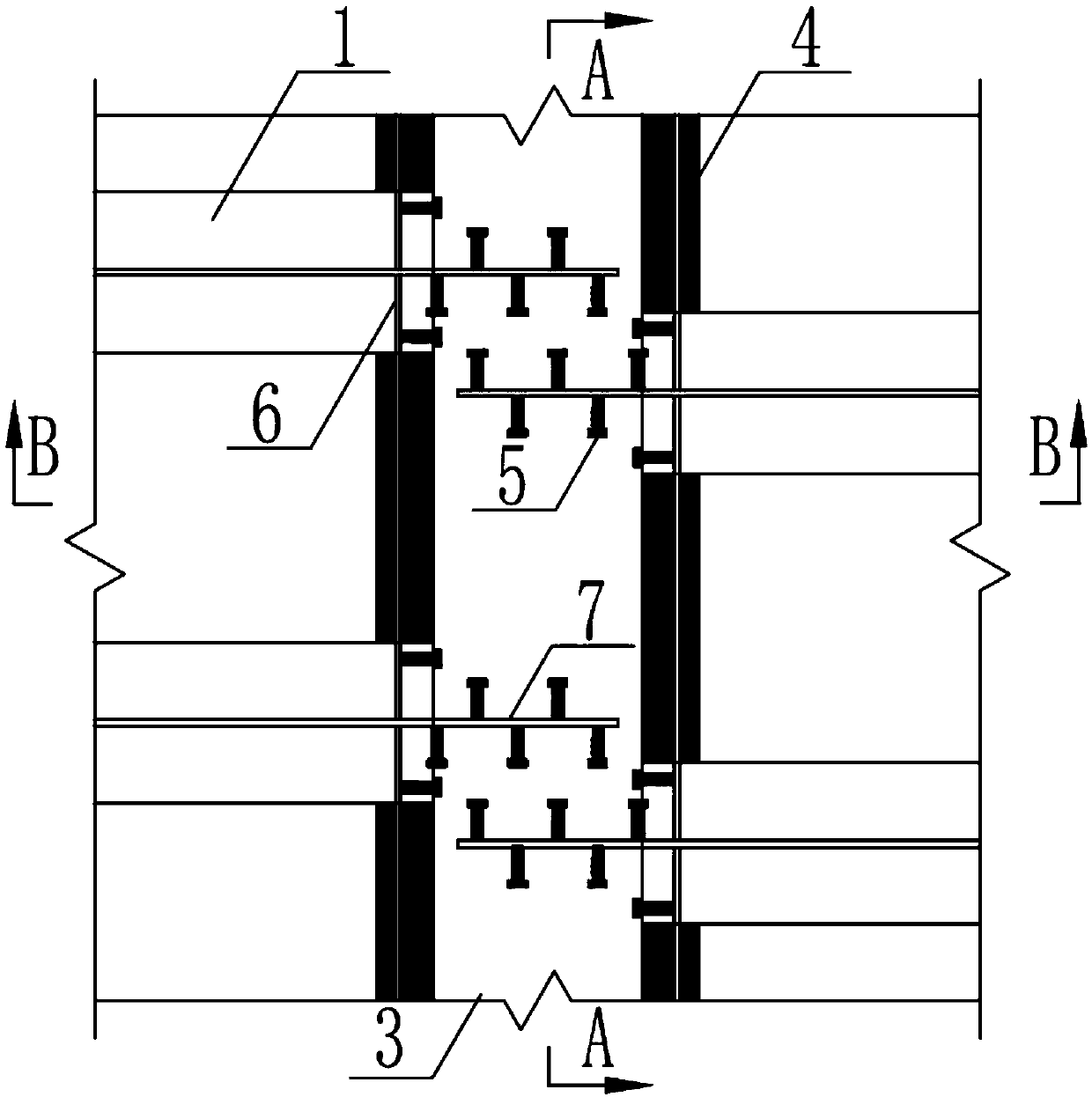

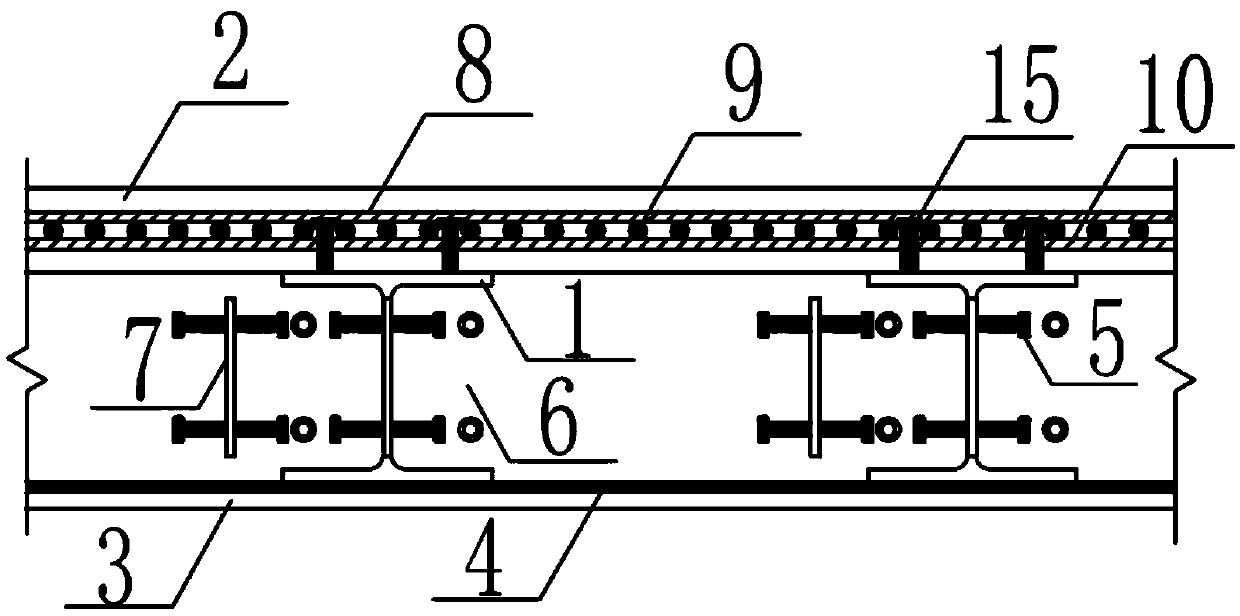

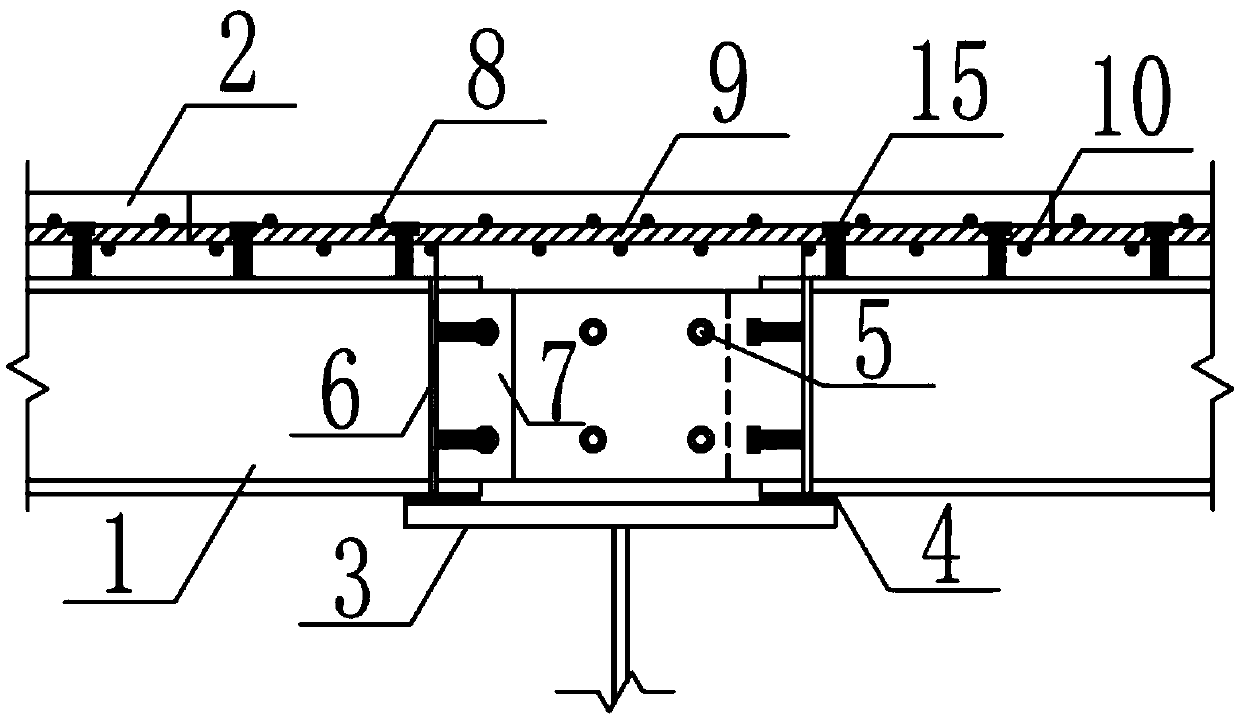

[0049] Refer to the attached Figures 1 to 3 , The present invention is a section steel-UHPC composite plate longitudinal rib staggered arrangement structure suitable for large-span bridges, mainly composed of an upper section steel-UHPC composite plate and a lower steel beam for arranging the section steel-UHPC composite plate. Rubber strips 4 for sealing are placed on both sides above the upper flange plate 3 of the clapboard or beam, and the section steel-UHPC composite board is directly placed above the rubber strip 4; the section steel-UHPC composite board is mainly composed of UHPC board 2 Combined with section steel 1, section steel 1 is arranged as a longitudinal rib along the longitudinal bridge direction, UHPC plate 2 is placed above section steel 1, and is connected to section steel 1 through the stud connector 15 between the UHPC plate and the upper flange of the section steel, and the UHPC plate is connected to the section steel 1. The stud connector 15 of the upp...

Embodiment 2

[0051] Refer to the attached Figures 4 to 6 , The present invention is a section steel-UHPC composite plate longitudinal rib staggered arrangement structure suitable for large-span bridges, mainly composed of an upper section steel-UHPC composite plate and a lower steel beam for arranging the section steel-UHPC composite plate. Rubber strips 4 for sealing are placed on both sides above the upper flange plate 3 of the clapboard or beam, and the section steel-UHPC composite board is directly placed above the rubber strip 4; the section steel-UHPC composite board is mainly composed of UHPC board 2 Combined with section steel 1, section steel 1 is arranged as a longitudinal rib along the longitudinal bridge direction, UHPC plate 2 is placed above section steel 1, and is connected to section steel 1 through the stud connector 15 between the UHPC plate and the upper flange of the section steel, and the UHPC plate is connected to the section steel 1. The stud connector 15 of the upp...

Embodiment 3

[0053] Refer to the attached Figures 7 to 9 , The present invention is a section steel-UHPC composite plate longitudinal rib staggered arrangement structure suitable for large-span bridges, mainly composed of an upper section steel-UHPC composite plate and a lower steel beam for arranging the section steel-UHPC composite plate. Rubber strips 4 for sealing are placed on both sides above the upper flange plate 3 of the clapboard or beam, and the section steel-UHPC composite board is directly placed above the rubber strip 4; the section steel-UHPC composite board is mainly composed of UHPC board 2 Combined with section steel 1, section steel 1 is arranged as a longitudinal rib along the longitudinal bridge direction, UHPC plate 2 is placed above section steel 1, and is connected to section steel 1 through the stud connector 15 between the UHPC plate and the upper flange of the section steel, and the UHPC plate is connected to the section steel 1. The stud connector 15 of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com