Flame-retardant artificial hair and preparation method thereof

A hair and man-made technology, applied in the manufacture of rayon, fire-retardant and flame-retardant filament, single-component polyester rayon, etc., can solve the problem of poor heat resistance, difficulty in achieving flame retardancy, Curl and other problems, to achieve good wear resistance, good gloss and mechanical strength, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Unless otherwise defined, the technical terms used in the following embodiments have the same meaning as commonly understood by those skilled in the art to which the present invention belongs. The test reagents used in the following examples, unless otherwise specified, are conventional biochemical reagents; the experimental methods, unless otherwise specified, are conventional methods.

[0029] The present invention will be described in detail below in conjunction with examples.

[0030] PET resin: PET BG80, intrinsic viscosity 0.8dl / g, Sinopec Yizheng Chemical Fiber,.

[0031] Brominated flame retardants: Decabromodiphenylethane, SAYTEX 4010, American Albemarle;

[0032] Sodium antimonate: SA-F, Chengdu Kaifei;

[0033] Silica: Gas-phase nano-silica with an average particle size of 100nm is used.

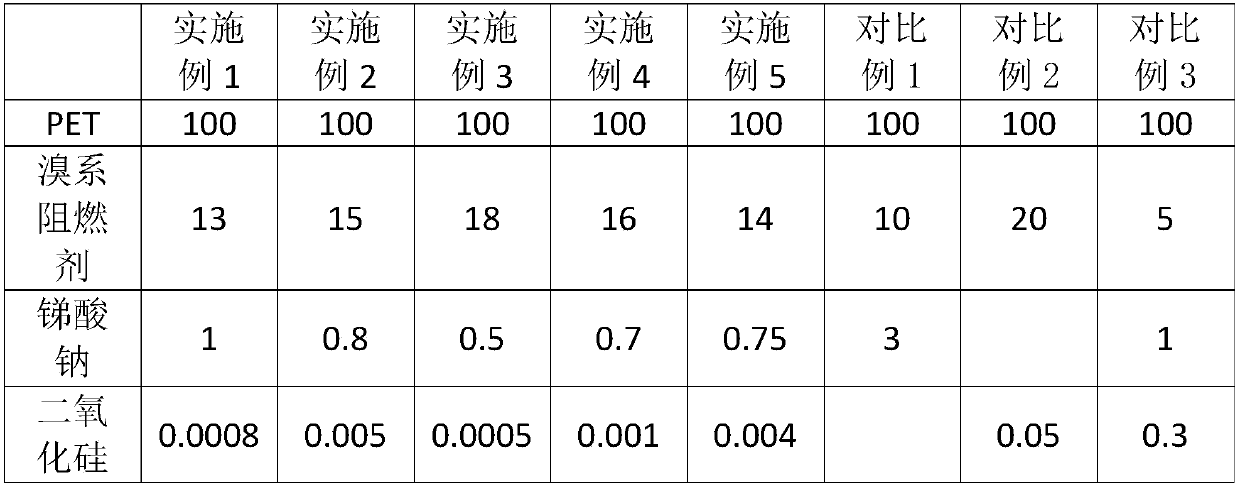

[0034] The specific added components and contents of Examples 1-5 and Comparative Examples 1-3 are shown in Table 1. The unit is Kg.

[0035] Carry out the preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com