Explosive bead compounded by flaxseed oil and walnut oil and oil plant squeezing device

A technology of linseed oil and walnut oil, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve problems such as easy to produce resistance, single form of consumption, exposure to oil smell, etc., and achieve good palatability , small size, soft and elastic taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A linseed oil walnut oil compound quick-fried beads, prepared by the following method:

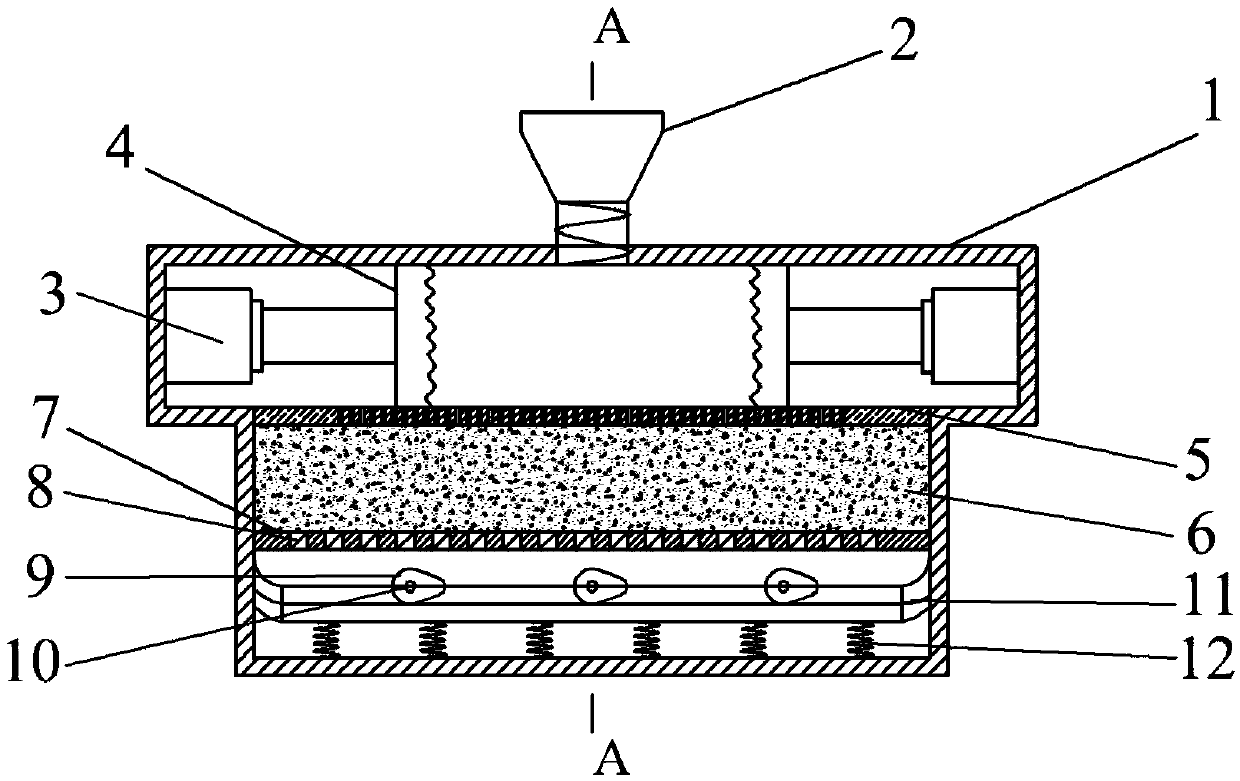

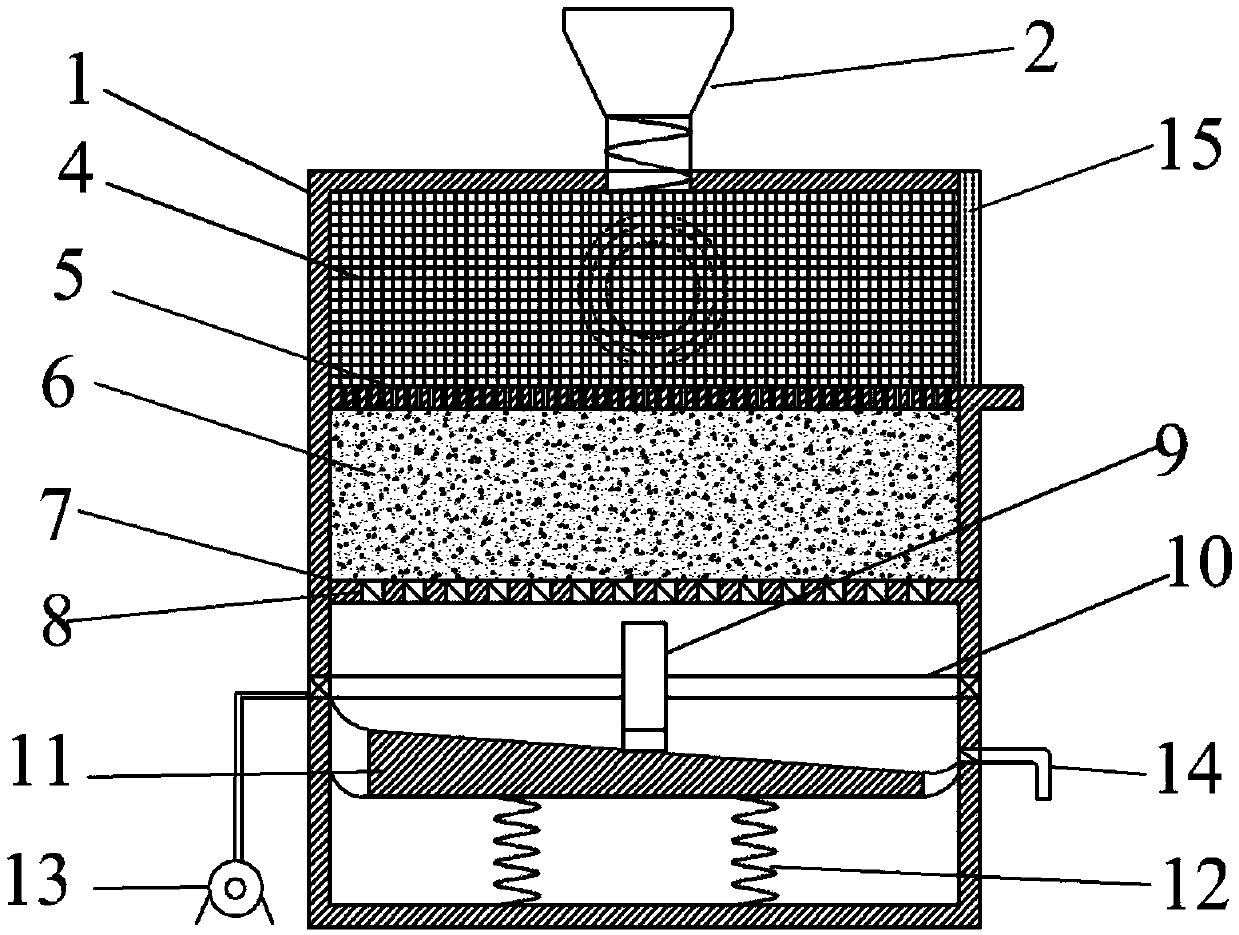

[0043] (1) Squeeze walnut oil: Shell the walnut raw materials, use a vibrating screen to screen out the walnut kernels and walnut shells with a diameter less than 20 mesh, put the walnut kernels in a bucket with a wave wheel, and add an appropriate amount of distilled water into the bucket , rotating and soaking at 100rpm; release the water in the bucket, wash away the remaining kernels on the walnut kernels with a water gun, remove the kernels and impurities, and obtain pure walnut kernels; dry the pure walnut kernels for several times Squeeze to get crude oil and oil residue;

[0044] (2) Separation of walnut oil and phospholipids: take crude oil and raise the temperature to 50°C, then add boiling water with 3.5 times the weight of phospholipid reserves, keep stirring at 50°C, and react for 2 hours; Carry out degumming, deacidification and decolorization treatment to obtain refin...

Embodiment 2

[0052] Step (1)~step (5) of present embodiment is the same as embodiment 1

[0053] (6) Compounding of oil products: compounding the walnut oil obtained in step (2) and the linseed oil prepared in step (4) with a weight ratio of 5:1;

[0054] (7) Core material preparation: Take the phospholipid prepared in step (2) and add it to the compound oil product in step (6), heat in a water bath, keep stirring at 50°C until the whole milky yellow color; then add the prepared in step (5) The obtained linseed gum is then added with lemon oil as a flavoring agent, stirred until the milky yellow gradually deepens, and homogenized three times to obtain the core material; the addition of the phospholipid is 0.1% of the total weight of the core material, and the linseed gum The addition is 1.2% of the total weight of the core material, and the addition of lemon oil is 20% of the total weight of the core material;

[0055] (8) Preparation of quick-fried pearls: cook the quick-fried pearl shel...

Embodiment 3

[0057] Step (1)~step (5) of present embodiment is the same as embodiment 1

[0058] (6) Compounding of oil products: compounding the walnut oil obtained in step (2) and the linseed oil prepared in step (4) with a weight ratio of 2:1;

[0059] (7) Core material preparation: Take the phospholipid prepared in step (2) and add it to the compound oil product in step (6), heat in a water bath, keep stirring at 50°C until the whole milky yellow color; then add the prepared in step (5) The obtained linseed gum is then added with lemon oil as a flavoring agent, stirred until the milky yellow gradually deepens, and homogenized three times to obtain the core material; the addition of the phospholipid is 0.2% of the total weight of the core material, and the linseed gum The addition is 0.6% of the total weight of the core material, and the addition of lemon oil is 20% of the total weight of the core material;

[0060] (8) Preparation of quick-fried pearls: cook the quick-fried pearl shel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com