Chemical Synthesis Process of Prednisolone Acetate Valerate

A kind of technology of prednisolone acetate valerate and prednisolone valerate is applied in the chemical synthesis process field of prednisolone acetate valerate, which can solve the problem of high cost, difficulty in mastering the technical process, and unsuitable Large-scale production and other issues, to achieve the effects of high yield and product purity, good market application prospects, and good industrial development value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

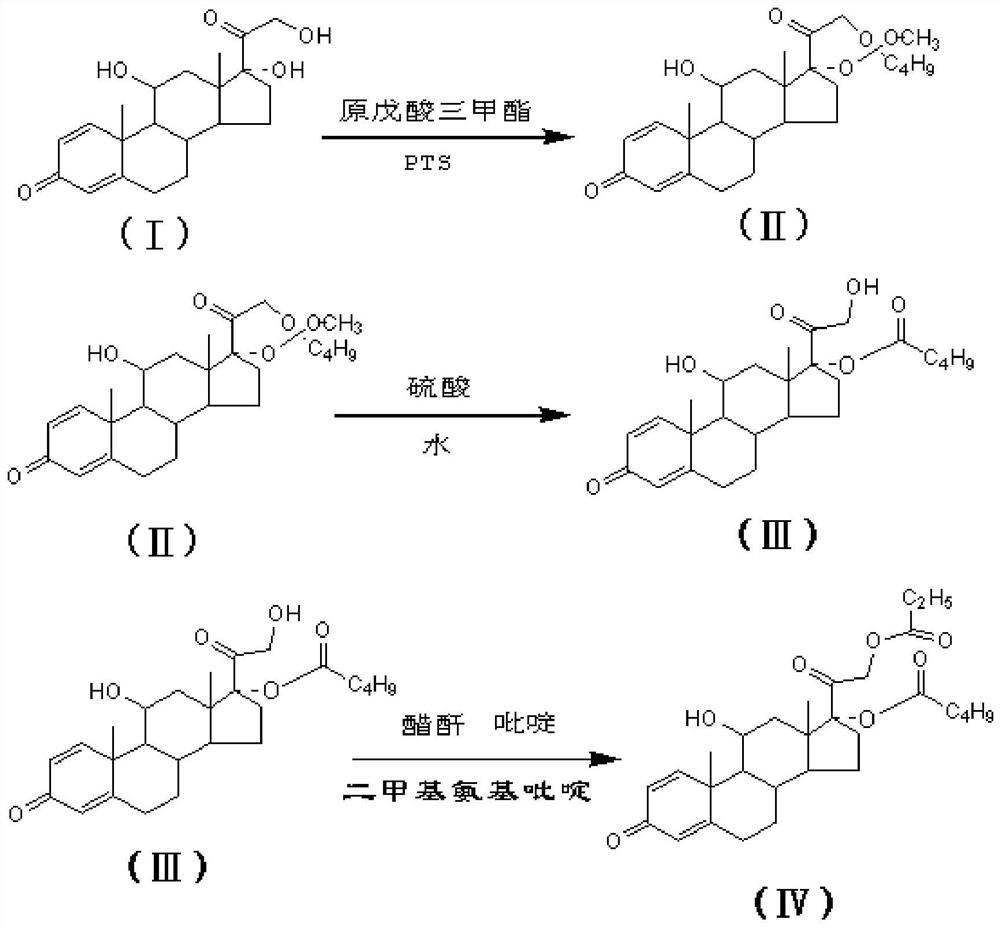

[0049] Embodiment 1 prednisolone acetate valerate chemical synthesis technique

[0050] Prednisolone valerate chemical synthesis technique, concrete steps are as follows:

[0051] S1: Add 20g of prednisolone to the reaction bottle, control the reaction temperature at 25°C, then add 25ml of a mixed solvent of dichloromethane and dimethyl sulfoxide with a volume ratio of 4:1, stir until the material is dissolved, and obtain Dissolve the system and turn on the nitrogen protection.

[0052]S2: Add 0.5 g of p-toluenesulfonic acid to the solution system in step S1, then add 30 mL of trimethyl orthovalerate, control the reaction temperature at 25°C, stir for 1 hour, and detect the content of prednisolone in the reaction system ≤1wt%, that is, the reaction is complete, and a reaction system containing cyclic esters is obtained.

[0053] S3: Reduce the temperature of the reaction system in step S2 to 20±2°C, add 3mL dilute sulfuric acid solution, then add 20mL acetone, control the re...

Embodiment 2

[0058] Embodiment 2, prednisolone acetate valerate chemical synthesis technique

[0059] Prednisolone valerate chemical synthesis technique, concrete steps are as follows:

[0060] S1: Add 20g of prednisolone to the reaction bottle, control the reaction temperature at 30°C, then add 20ml of dichloromethane and dimethyl sulfoxide with a volume ratio of 8:1, and stir until the material is dissolved to obtain a dissolved system , turn on the nitrogen protection.

[0061] S2: Add 0.6g of p-toluenesulfonic acid to the solution system of step S1, then add 32mL of trimethyl orthovalerate, control the reaction temperature at 30°C, and stir for 1 hour to detect the prednisolone in the reaction system The content of ≤1wt%, that is, the reaction is complete, and the reaction system containing the cyclic ester (II) is obtained.

[0062] S3: Reduce the reaction temperature of the reaction system in step S2 to 20±2°C, add 4mL of dilute sulfuric acid solution, and then add 22mL of acetone,...

Embodiment 3

[0067] Embodiment 3, prednisolone acetate valerate chemical synthesis technique

[0068] Prednisolone valerate chemical synthesis technique, concrete steps are as follows:

[0069] S1: Add 20g of prednisolone to the reaction bottle, control the reaction temperature at 20°C, then add 22ml of dichloromethane and dimethyl sulfoxide with a volume ratio of 6:1, and stir until the material is dissolved to obtain a dissolved system , turn on the nitrogen protection.

[0070] S2: Add 0.8g of p-toluenesulfonic acid to the solution system of step S1, then add 35mL of trimethyl orthovalerate, control the reaction temperature at 20°C, stir and react for 2 hours, and detect the content of prednisolone in the reaction system ≤1wt%, that is, the reaction is complete, and a reaction system containing cyclic esters is obtained.

[0071] S3: Reduce the reaction temperature of the reaction system in step S2 to 20±2°C, add 5mL of dilute sulfuric acid solution, then add 25mL of acetone, control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com