Machining technique for equal-height sleeve

A technology of contour sleeve and processing technology, which is applied in the direction of metal material coating technology, etc., can solve the problems of large tolerance and impact on the service life of the mold, and achieve the effect of improving service life and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0044] A processing technology for a contour sleeve, comprising the following steps:

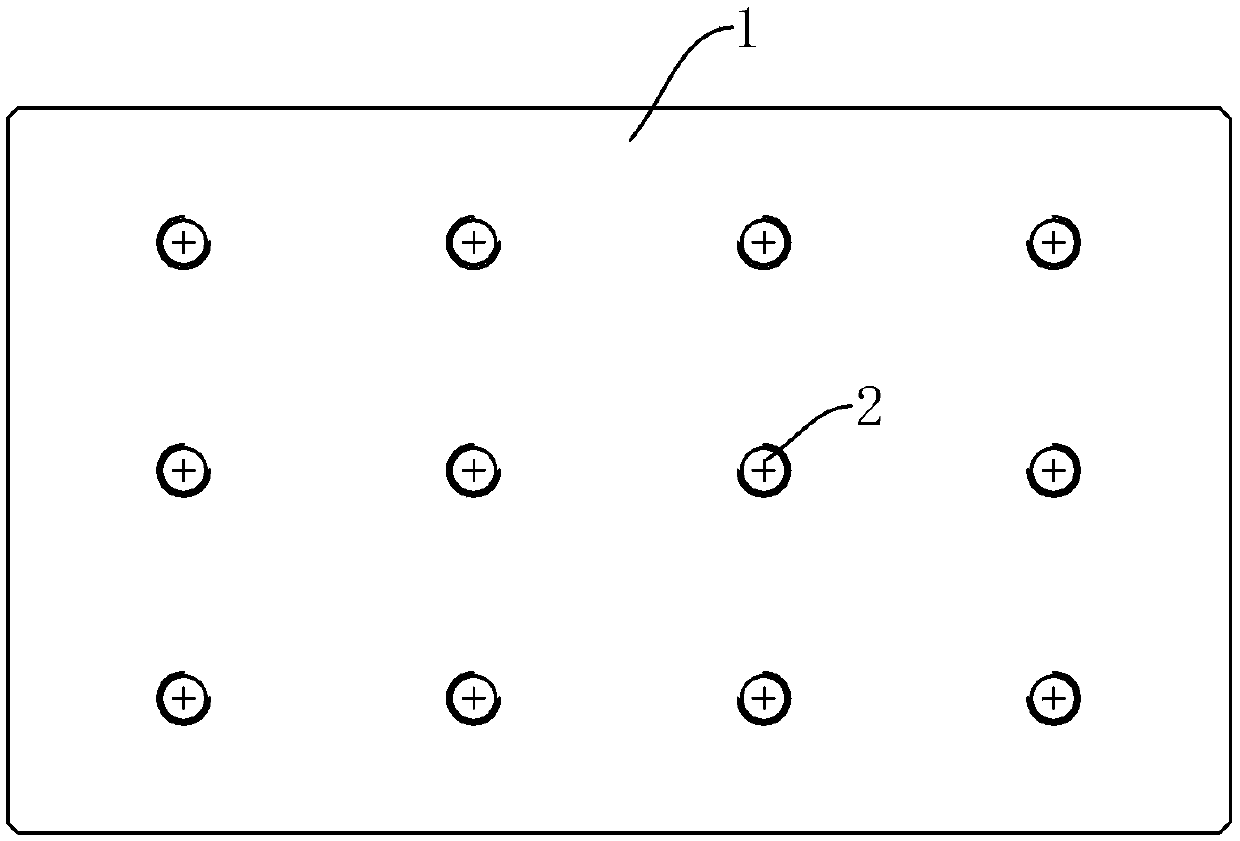

[0045] Step 1, prepare a fixed seat 1 with a flat surface, and the upper end surface of the fixed seat 1 is provided with a number of threaded holes 2 for standby;

[0046] Wherein, before the fixed seat 1 is used each time, a grinding machine must be used for actual verification.

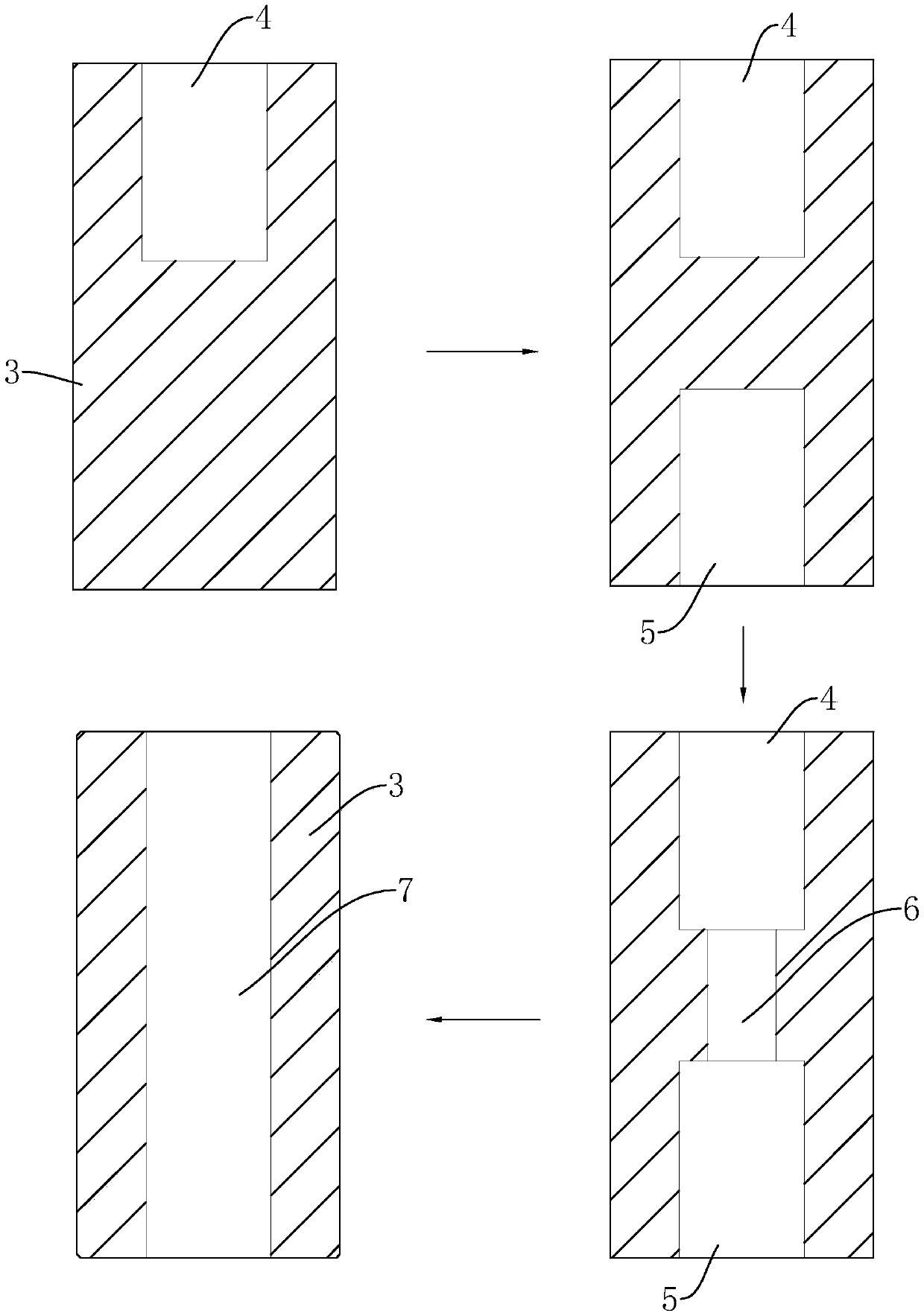

[0047] Step 2, cold pressing of raw materials to obtain columnar material 3;

[0048] Step 3, fix one end of the column material 3 with a precision vise and mark it as side A, and ground the other end and mark it as side B;

[0049] Among them, grinding is processed by hand-operated Yuqing grinder.

[0050] Step 4: Open the first relief groove 4 and the second relief groove 5 on the A surface and the B surface of the column material 3 respectively, and open the relief hole 6 between the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com