Cleaning machine sewage discharging device with rotary throwing-out type sewage stirring precipitation prevention

An excretion device and anti-sedimentation technology, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of increasing dirt on workpiece wear, muddy water, and residual stains, so as to avoid sewage precipitation. , to avoid the effect of subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

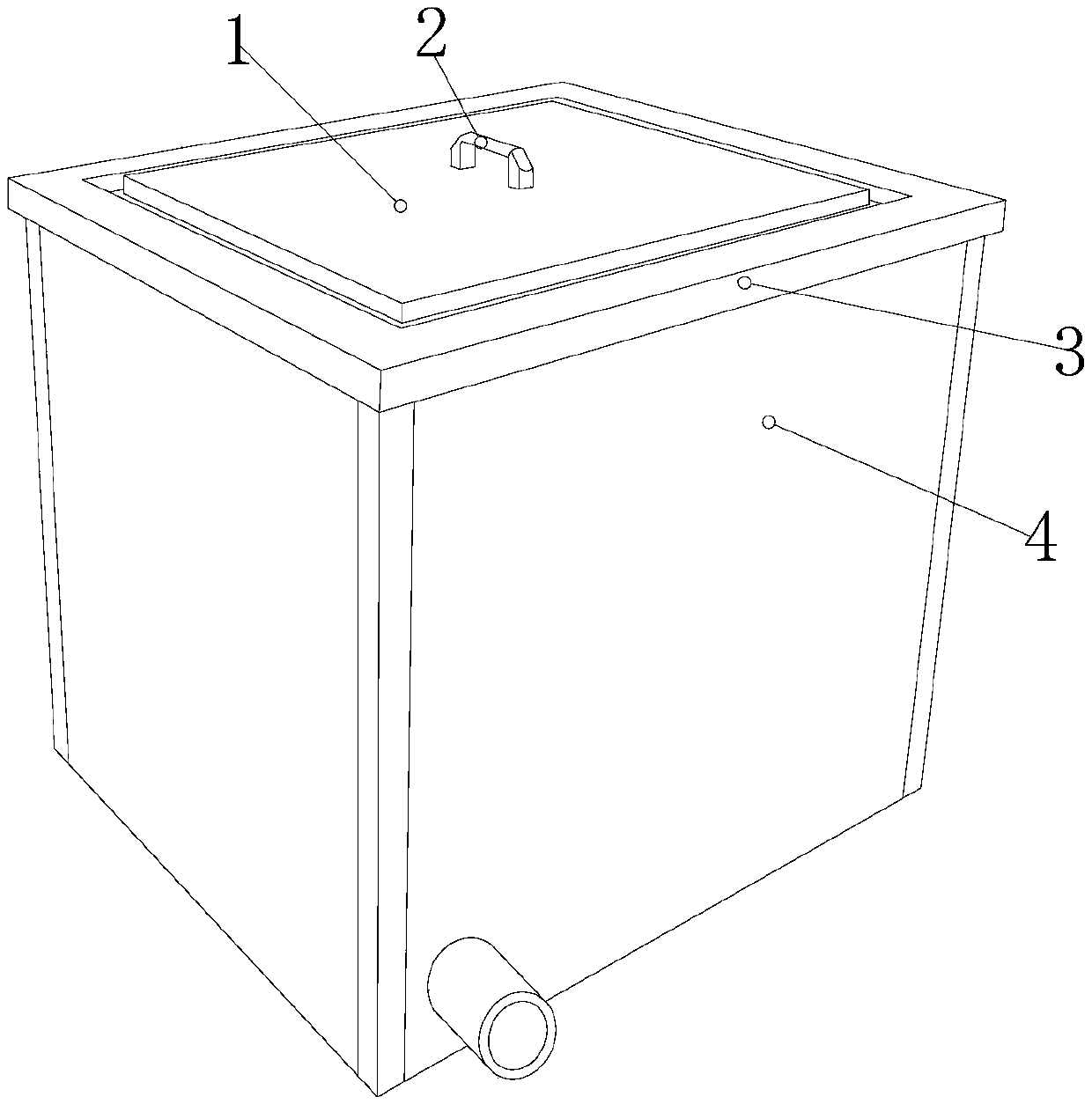

[0025] see Figure 1-Figure 6 , the present invention provides a sewage discharge device for a cleaning machine with rotary throw-out type sewage stirring and anti-precipitation, its structure includes a cover 1, a handle 2, a cleaning shell 3, and a drainage device 4. The drainage device 4 is fixedly installed in the cleaning shell 3, the handle 2 is installed in the center of the top panel of the cover 1, and the cover 1 and the handle 2 are mechanically welded.

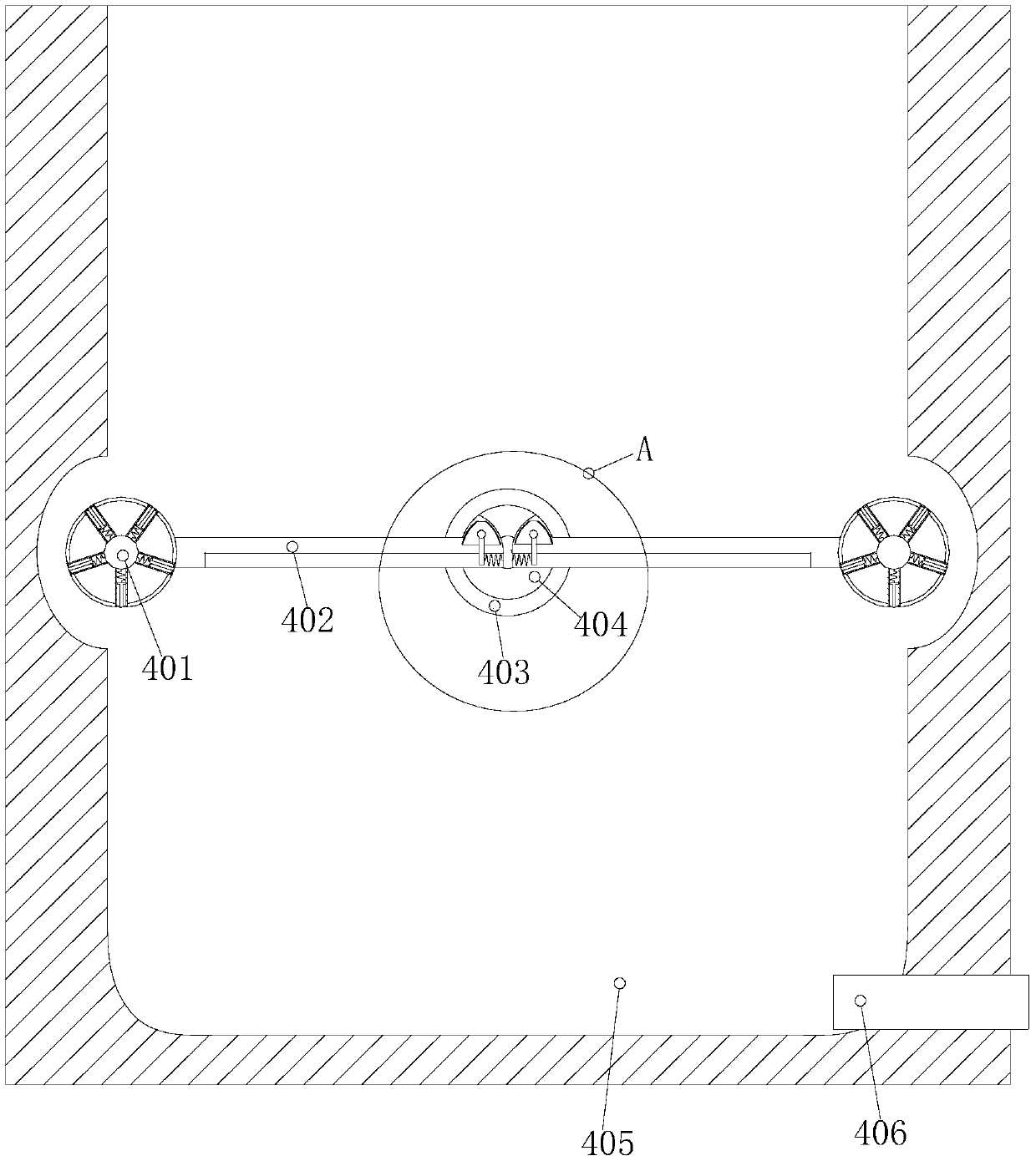

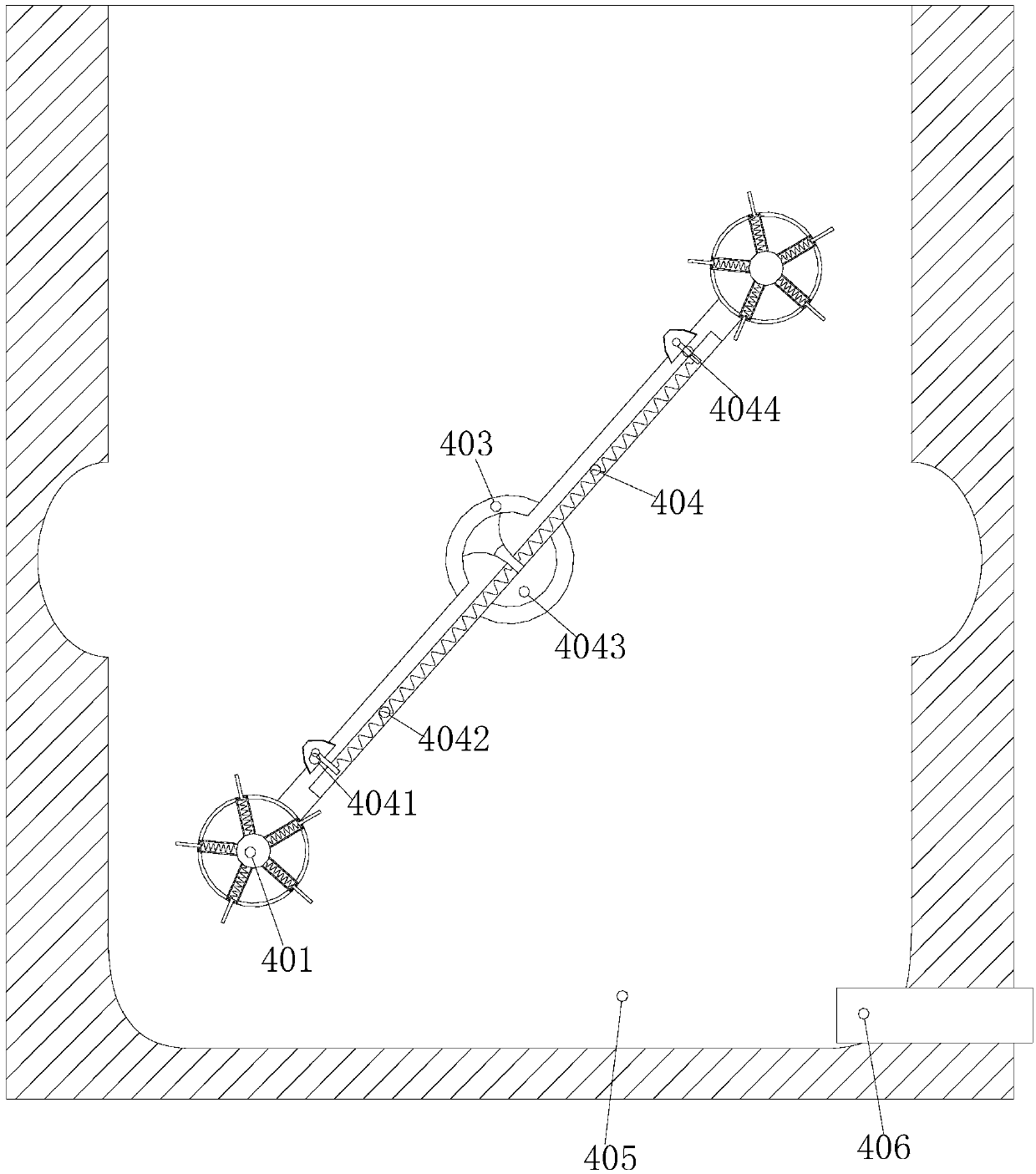

[0026] The drainage device 4 is composed of an anti-sedimentation mechanism 401, a fixed connecting rod 402, a turntable 403, an anti-slagging mechanism 404, a cleaning chamber 405, and a drain pipe 406. The anti-slagging mechanism 404 is mechanically connected with the turntable 403, and the The turntable 403 is connected with the anti-sedimentation mechanism 401 through the fixed connecting rod 402, the anti-sedimentation mechanism 401 is installed in the cleaning chamber 405, the turntable 403 is arranged in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com