Nuclear track membrane and electrostatic spinning composite membrane and preparation method and application thereof

A technology of electrospinning and electrospinning liquid, which is applied in the field of nuclear pore membrane and electrospinning composite membrane and its preparation, which can solve the problem of different pore sizes, uneven surface of non-woven fabrics, poor air permeability of materials, etc. problems, achieve long service life, improve retention performance, and improve air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Composite membrane of nuclear pore membrane and electrospinning and its preparation method

[0039] Prepare the composite membrane of nuclear pore membrane and electrospinning according to the following method:

[0040] (1) Composite the nuclear pore membrane and the non-woven fabric by hot pressing, the hot pressing temperature is 80°C, the time is 10 seconds, and the pressure is 0.5 bar;

[0041] (2) The polymer material PLA and the electrospinning solution dimethylacetamide are prepared as an electrospinning solution; the electrospinning solution is formed into nanofibers and sprayed on the surface of the nuclear pore membrane through an electrospinning device.

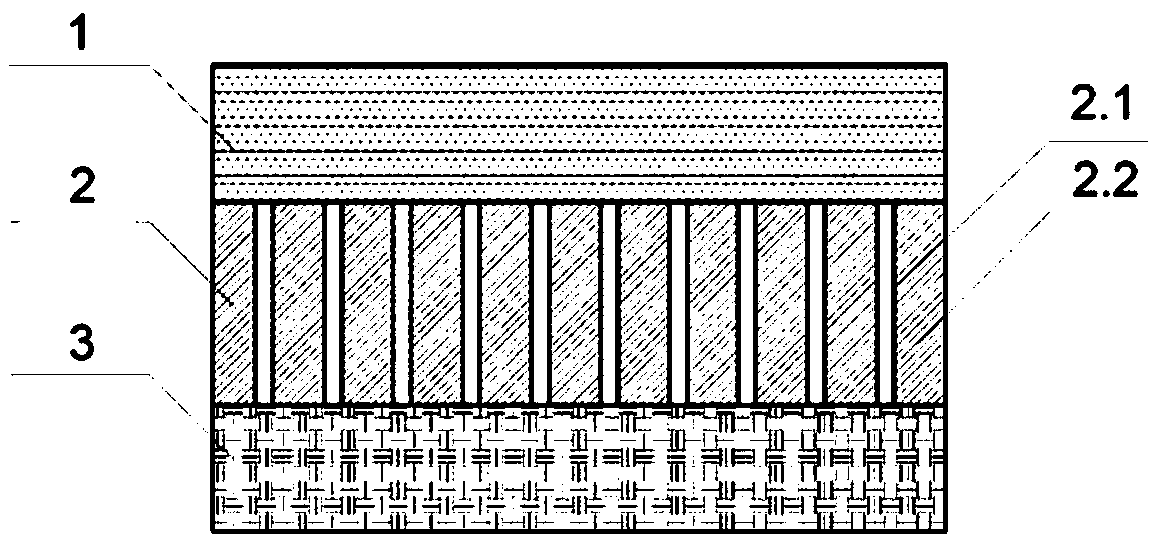

[0042] The composite membrane of nuclear pore membrane and electrospinning obtained in this embodiment is composed of base material, nuclear pore membrane and electrospinning successively from bottom to top, such as figure 1 shown.

[0043] Wherein, the material constituting the electrospinning is...

Embodiment 2

[0046] Example 2: Composite membrane of nuclear pore membrane and electrospinning and its preparation method

[0047] Prepare the composite membrane of nuclear pore membrane and electrospinning according to the following method:

[0048] (1) Composite the nuclear pore membrane and the non-woven fabric by hot pressing, the hot pressing temperature is 100°C, the time is 15 seconds, and the pressure is 0.5 bar;

[0049] (2) The polymer material PVDF and the electrospinning solution dimethylacetamide are prepared as an electrospinning solution; the electrospinning solution is formed into nanofibers and sprayed on the surface of the nuclear pore membrane through an electrospinning device.

[0050] The composite membrane of nuclear pore membrane and electrospinning obtained in this embodiment is composed of base material, nuclear pore membrane and electrospinning successively from bottom to top, such as figure 1 shown.

[0051] Wherein, the material constituting the electrospinnin...

Embodiment 3

[0054] Example 3: Composite membrane of nuclear pore membrane and electrospinning and its preparation method

[0055] Prepare the composite membrane of nuclear pore membrane and electrospinning according to the following method:

[0056] (1) Composite the nuclear pore membrane and the non-woven fabric by hot pressing, the hot pressing temperature is 120°C, the time is 10 seconds, and the pressure is 0.5 bar;

[0057] (2) The polymer material PAN and the electrospinning solution dimethylacetamide are prepared as an electrospinning solution; the electrospinning solution is formed into nanofibers and sprayed on the surface of the nuclear pore membrane through an electrospinning device.

[0058] The composite membrane of nuclear pore membrane and electrospinning obtained in this embodiment is composed of base material, nuclear pore membrane and electrospinning successively from bottom to top, such as figure 1 shown.

[0059] Wherein, the material constituting the electrospinning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com