Straw-burning smoke treating system

A technology for processing systems and dust, applied in gas treatment, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of poor dust removal effect and low dust removal efficiency, so as to increase the speed of rotation, improve the effect and prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

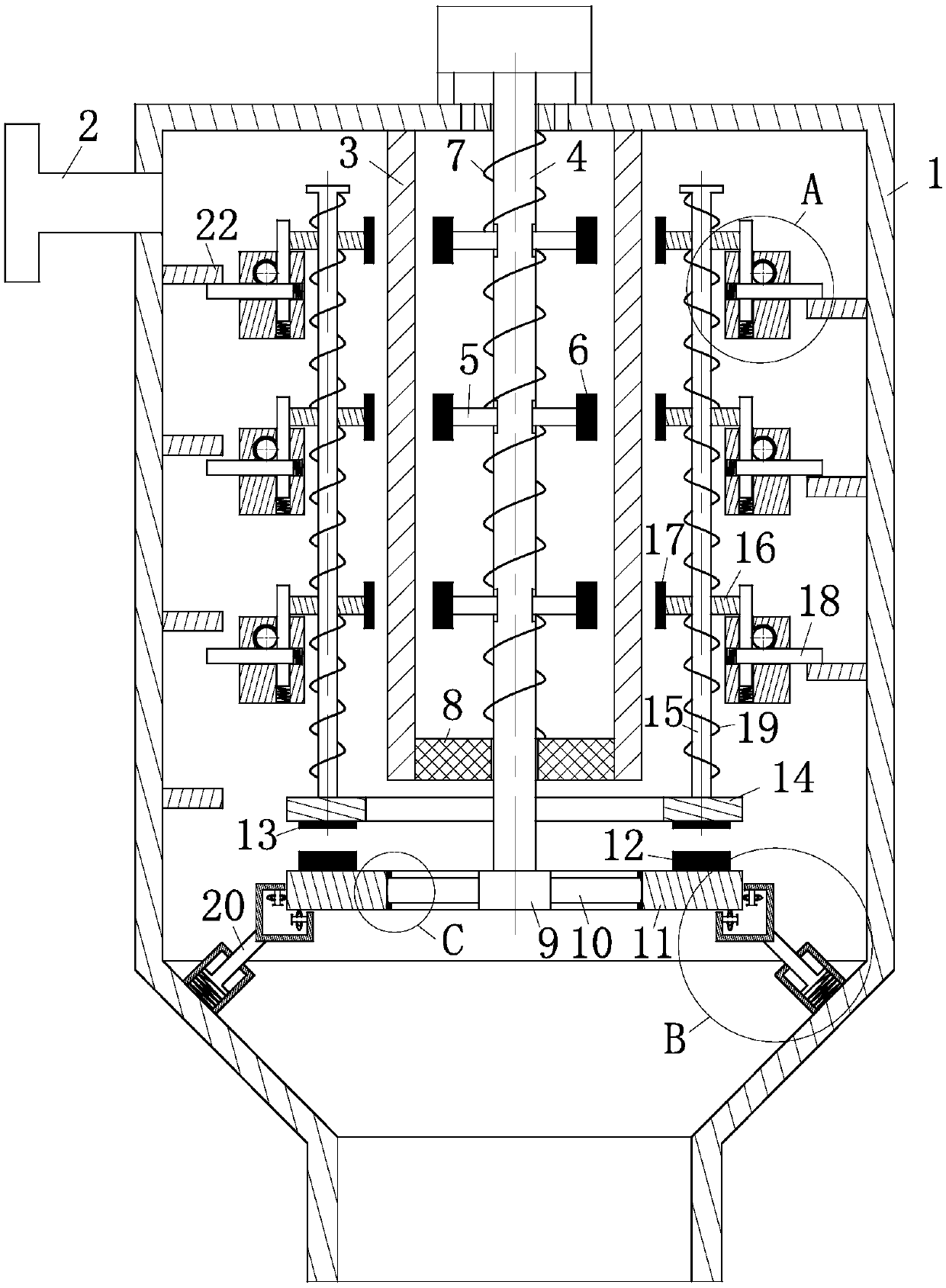

[0022] use Figure 1-Figure 4 A straw combustion soot processing system according to an embodiment of the present invention will be described as follows.

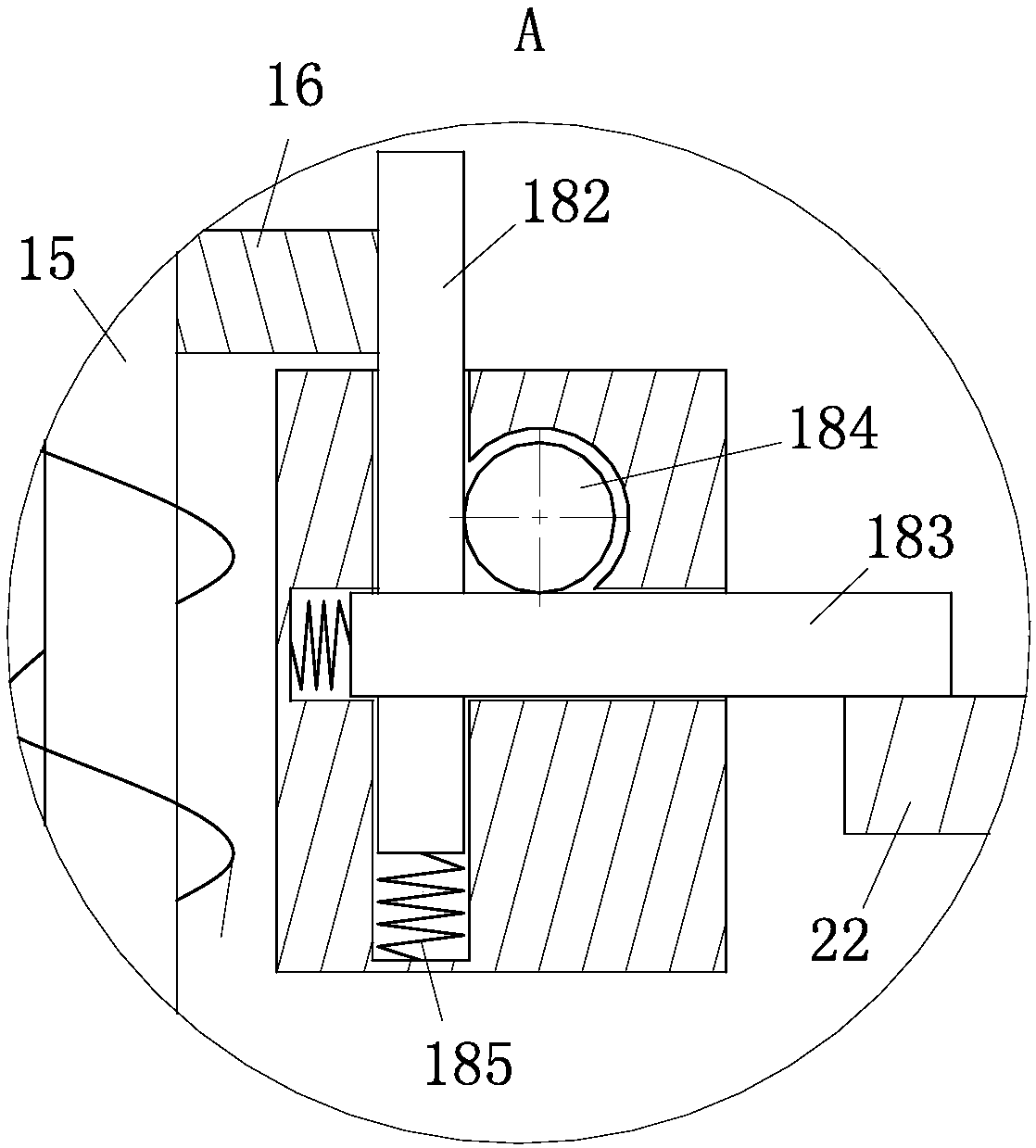

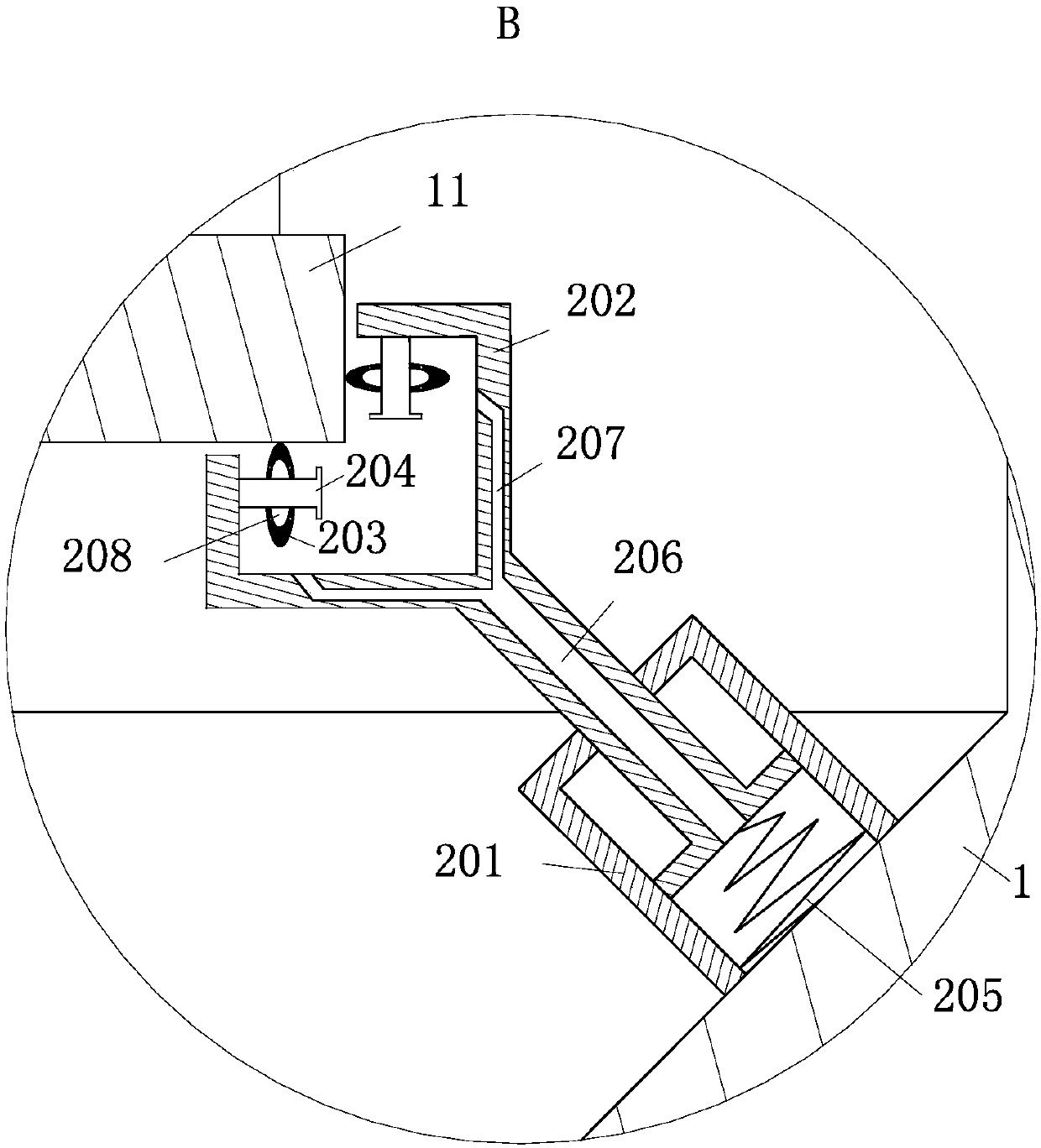

[0023] Such as figure 1 with figure 2 As shown, the straw burning smoke and dust processing system of the present invention includes a box body 1 and a smoke inlet 2 arranged on the upper part of the box body 1; A fixed cylinder 3 is connected; the central axis of the output end of the motor and the central axis of the fixed cylinder 3 are on the same vertical line, and the output end of the motor is fixedly connected to a rotating shaft 4; Group chute, each chute is slidably connected with a horizontal connecting rod 5, the end of the connecting rod 5 away from the No. 1 shaft 4 is provided with a No. 1 magnet 6, and a No. 1 magnet 6 is arranged between each group of connecting rods 5 Spring 7; the No. 1 spring 7 is sleeved on the No. 1 shaft 4; the box 1 above the fixed cylinder 3 is provided with an exhaust hole, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com