Manufacture method of energy balls incorporated with microencapsulated mulberry polyphenols

A technology of microencapsulation and production method, which is applied in the functions of food ingredients, the forming of food, and the use of food ingredients as antioxidants, etc., to achieve the effects of broadening the scope of application, high absorption rate, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of embodiment 1 microencapsulated mulberry polyphenols

[0048] Mulberry juice microparticles were prepared by applying spray drying technique with the help of different kinds of wall materials. A monomorphic lattice design with 3 factors (maltodextrin, gum arabic and whey protein), 3 interior points and 1 center point was generated in a total of 10 runs. We chose these wall materials because of their higher recovery and solubility than other materials.

[0049] Based on the integral ratio of the raw material mulberry juice and the solid total soluble solids (1:0.25) of the carrier material, the integral ratio is calculated as 1.9375g per 100mL of raw juice (the total soluble solid content in each 100ml fruit juice is 7.75), in order to achieve the lowest Applicable mix rate. Therefore, the feed mixture was microencapsulated using a laboratory-scale spray dryer with inlet and outlet temperatures of 110 ± 1 °C and 85 ± 1 °C, respectively. The feed solu...

Embodiment 2

[0055] Embodiment 2 prepares and formulates energy ball with MMPs

[0056] We developed new energy ball formulations adding several ratios of MMPs, as shown in Table 2. 25.0 g of glucose was mixed with 25.0 g of aqueous solution at room temperature and heated to 102±1°C in a stainless steel vessel, then 8.3 g of cocoa butter was added and the vessel was cooled at room temperature. While the sugar-water-cocoa butter syrup was cooling, 90.0 g whey protein and 0.01 g sodium benzoate were added to the beaker, then 60 g glycerin was added and mixed for 30 seconds. The microencapsulated mulberry polyphenols prepared in Example 1, the cooled glucose syrup were added to the whey protein-glycerin mixture in the beaker, and mixed with a stirrer until the texture was uniform. After resting for 1 minute, the mixture was manually shaped into small balls and placed in plastic cups, double sealed with parafilm to avoid moisture loss. Finally, the cups were placed in a double-sealed desicca...

Embodiment 3

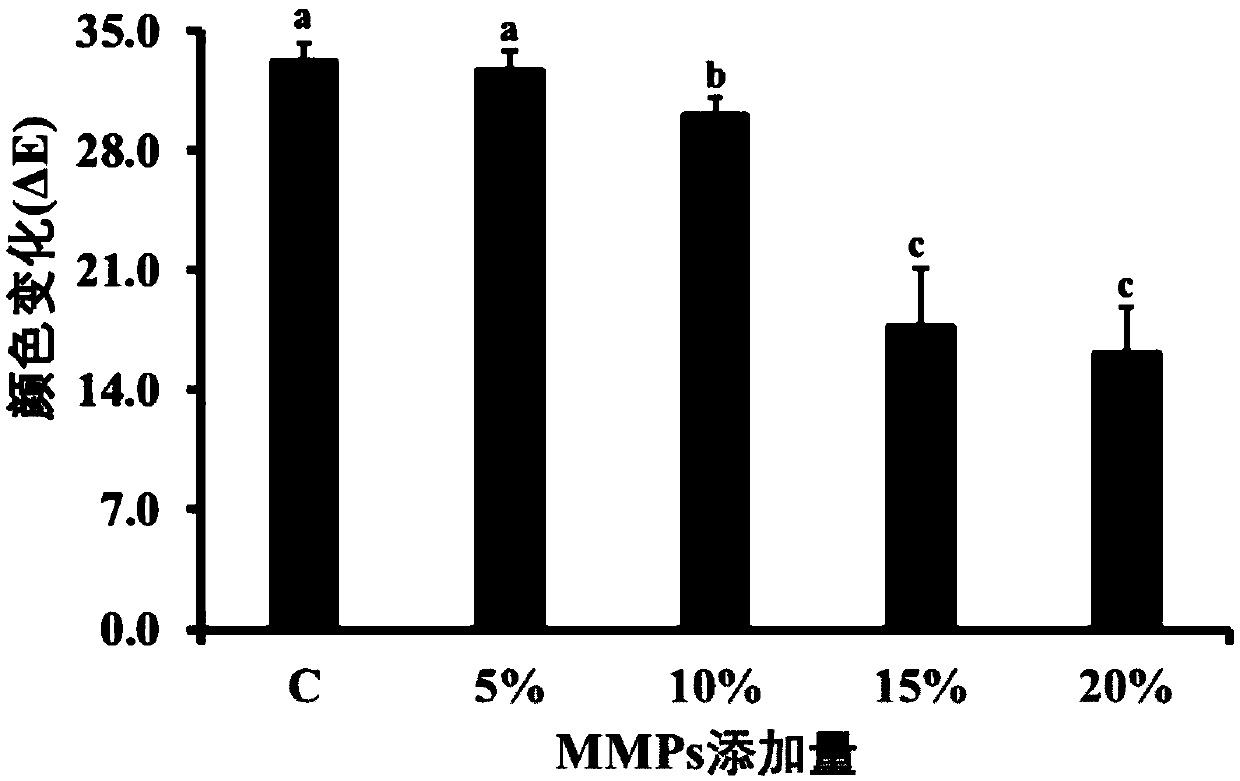

[0063] Embodiment 3 adds MMPs to the influence of energy ball color change

[0064] Adopt the proportioning of embodiment 2 table 3, control group is the energy ball that does not add MMPs, after storing for 45 days Measure the color change (ΔE) of each energy ball. Such as figure 1 As shown, MMPs significantly reduced the ΔE value of energy balls during storage, especially the ΔE value of energy balls with high MMPs ratio (≥15%) was significantly lower than that of other energy balls (pfigure 1 The one whose middle abscissa is C is the control group) 51.50% lower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com