Measuring experimental device for fission gas leakage after fuel element damage and experimental method thereof

A fission gas and experimental device technology, applied in the direction of reducing greenhouse gases, climate sustainability, nuclear reactor monitoring, etc., can solve the problems of long measurement time and complex device, and achieve the effects of convenient operation, easy processing and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

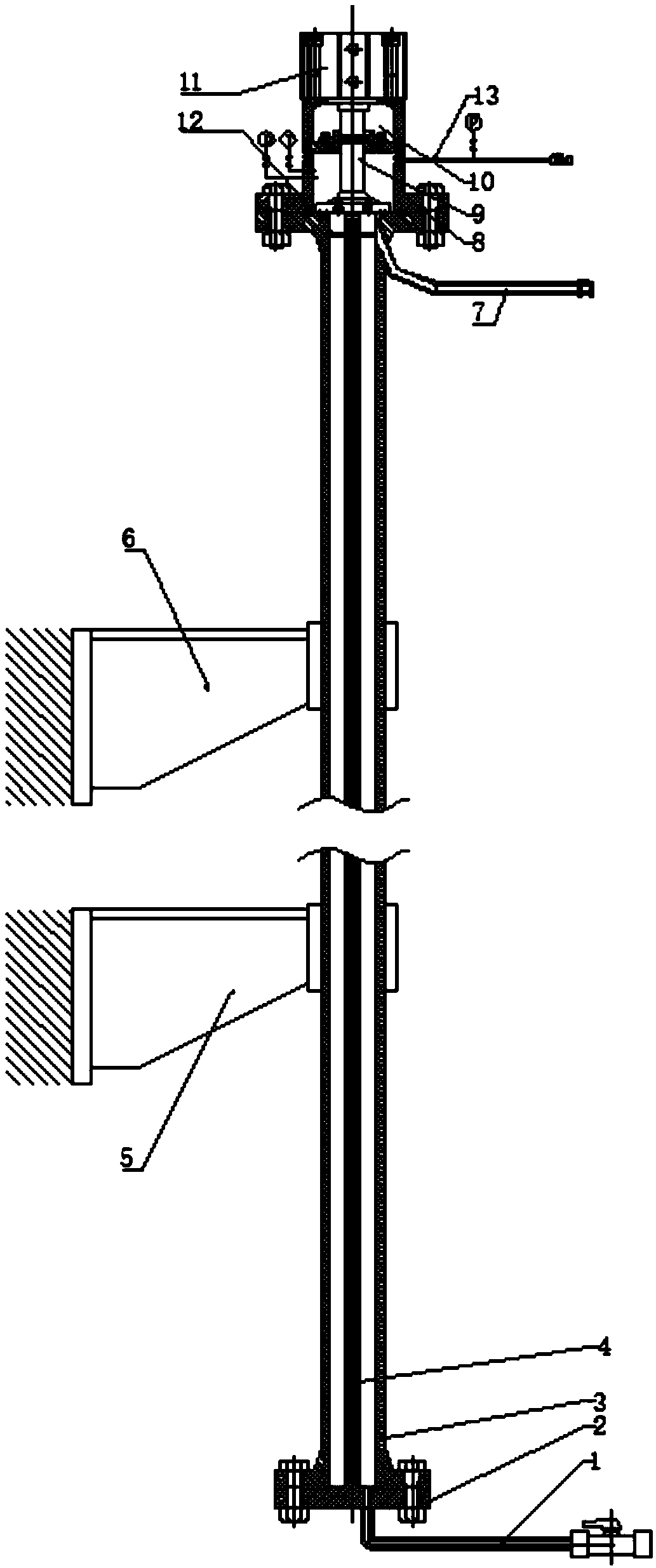

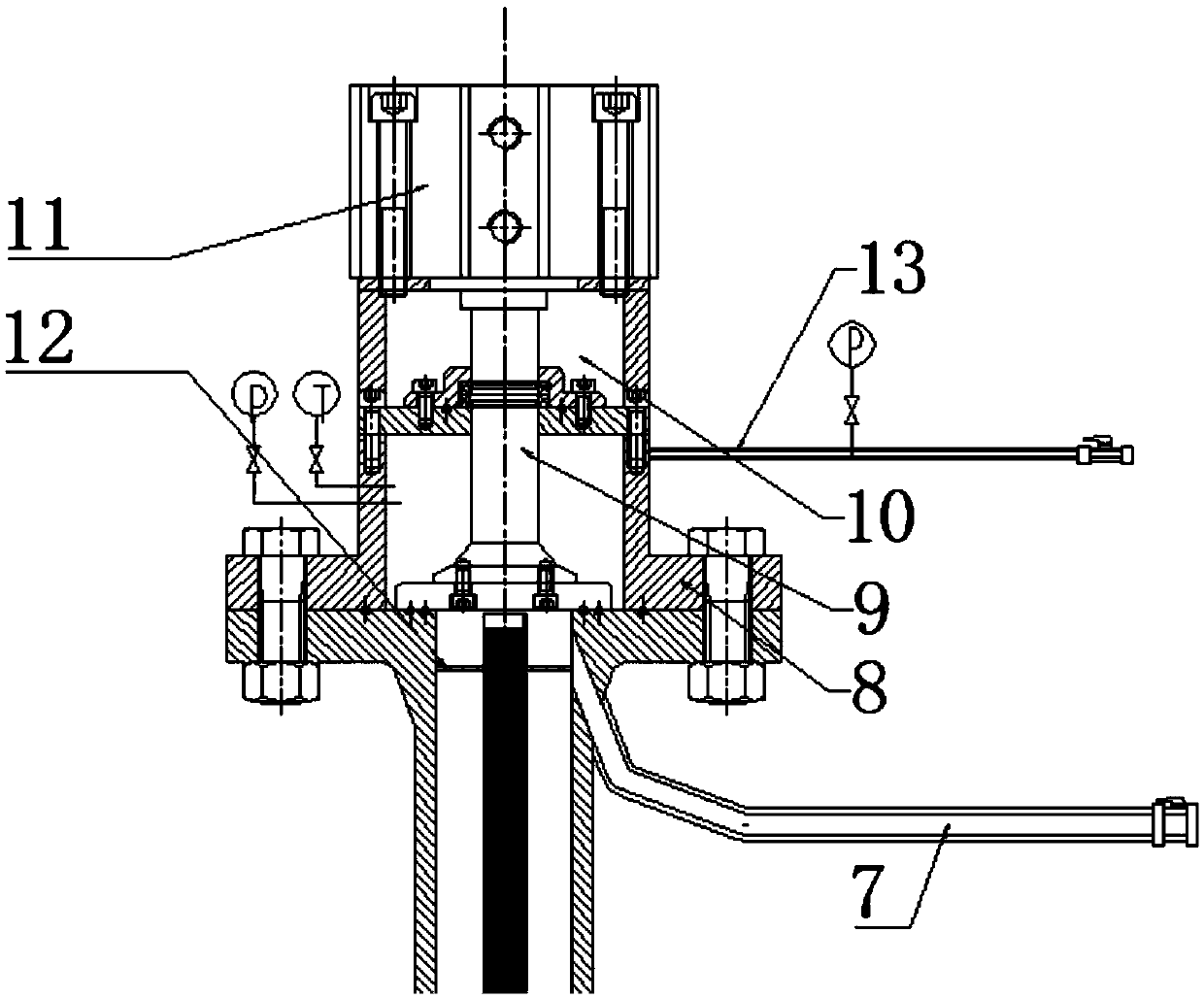

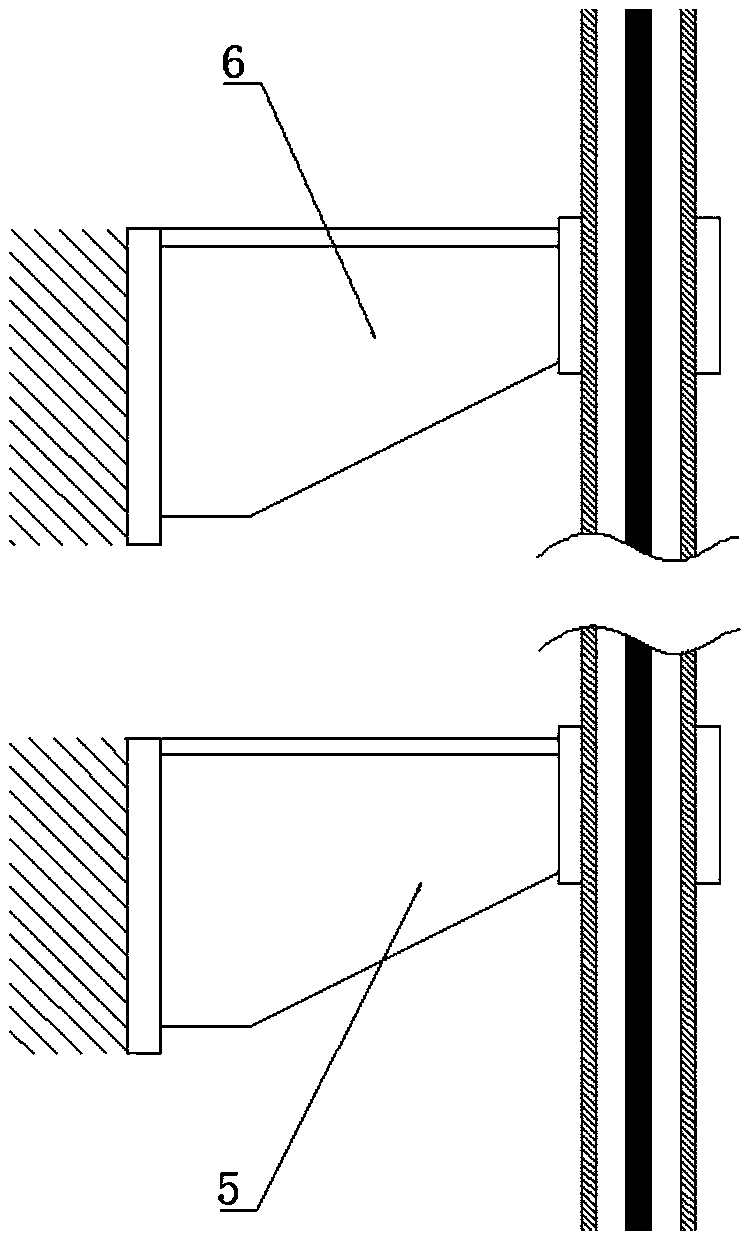

[0019] like figure 1 , image 3 and Figure 4 As shown, a fission gas leakage measurement experimental device after a fuel element is damaged according to the present invention includes a water inlet pipe 1 located at the lower part of the entire experimental device for water passage; a lower sealing cover 2 connected with the water inlet pipe 1; and The sealing tank 3 connected with the lower sealing cover; the pumping chamber 8 connected with the sealing tank 3; the outlet pipe 7 is connected with the sealing tank 3; the first fixing device 5 and the second fixing device 6 are used to fix the whole sealing tank 3 The fuel rod fixing ring 12 is used to fix the fuel rod 4 in the sealed tank 3, so that the fuel rod 4 will not move up and down; the pumping chamber 8 is connected to the lifting console 11 through the connecting chamber 10; Lifting in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com