Preparation method of ultrapure ferritic stainless steel spectral standard sample

A spectral standard sample, stainless steel technology, applied in color/spectral characteristic measurement, manufacturing tools, casting and molding equipment, etc., can solve the problems of large difference in matrix effect, sample inspection and detection deviation, precise control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

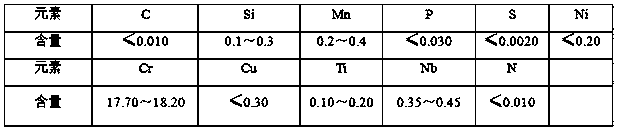

[0050] This embodiment is the preparation method of 436 L series ultra-pure ferritic stainless steel spectral standard sample. The data in Table 1 are 436L series

[0051] List the general requirements for the chemical composition of stainless steel.

[0052] Table 1 436L series stainless steel chemical composition range table (%)

[0053]

[0054] Step 1. Billet mold design

[0055] The inner dimension of the billet mold is designed to be 70mm×200mm×270mm;

[0056] Step 2. Billet mold baking preheating

[0057] After cleaning the billet mold used, bake it at a temperature of 800°C for 2 hours, and then cool it naturally;

[0058] Step 3. Composition Design

[0059] Refer to the national standard GB / T 20878-2007 "Stainless Steel Heat-resistant Steel Grades and Chemical Composition" for composition design, see Table 1.

[0060] Step 4, the choice of charging material

[0061] 436 L ultra-pure ferritic stainless steel trimmings after rolling are used as furnace materia...

Embodiment 2

[0085] This embodiment is a preparation method of 441 series ultra-pure ferritic stainless steel spectral standard samples. The data in Table 5 is for 441 series not

[0086] General requirements for the chemical composition of stainless steel.

[0087] Table 5 441 series stainless steel chemical composition range table (%)

[0088]

[0089] Step 1. Billet mold design

[0090] The inner dimension of the billet mold is designed to be 70mm×200mm×270mm;

[0091] Step 2. Billet mold baking preheating

[0092] After cleaning the billet mold used, bake it at a temperature of 600°C for 3 hours, and then cool it naturally;

[0093] Step 3. Composition Design

[0094] Refer to the national standard GB / T 20878-2007 "Stainless Steel Heat-resistant Steel Grades and Chemical Composition" for composition design, see Table 5.

[0095] Step 4, the choice of charging material

[0096] The 441 ultra-pure ferritic stainless steel trimmings after rolling are used as the furnace material...

Embodiment 3

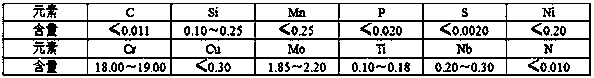

[0120] This embodiment is a preparation method of 444 series ultra-pure ferritic stainless steel spectral standard samples. The data in Table 9 is for 444 series not

[0121] General requirements for the chemical composition of stainless steel.

[0122] Table 9 444 series stainless steel chemical composition range table (%)

[0123]

[0124] Step 1. Billet mold design

[0125] The inner dimension of the billet mold is designed to be 70mm×200mm×270mm;

[0126] Step 2. Billet mold baking preheating

[0127] After cleaning the billet mold used, bake it at a temperature of 500°C for 4 hours, and then cool it naturally;

[0128] Step 3. Composition Design

[0129] Refer to the national standard GB / T 20878-2007 "Stainless Steel Heat-resistant Steel Grades and Chemical Composition" for composition design, see Table 9.

[0130] Step 4, the choice of charging material

[0131] The 444 ultra-pure ferritic stainless steel trimmings after rolling are used as the furnace material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com