Test fixture for tensile test of viscous-elastic materials under micro scale and test method

A technique for tensile testing and testing fixtures, which is applied in the analysis of materials, strength characteristics, and the use of repeated force/pulsation force to test the strength of materials, etc., and can solve the problems of inability to accurately measure viscoelastic constitutive parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

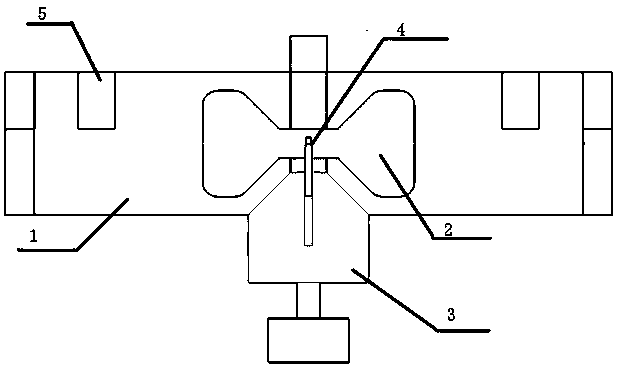

[0029] Such as figure 1 and figure 2 As shown, the test fixture for the tensile test of viscoelastic materials at the microscopic scale is composed of the main mold 1, the recessed material pouring area 2, the prefabricated crack module 3, the prefabricated crack needle point 4, the chassis 6 and the chassis clamping groove 5, and the main mold (1 ) size is 69.8mm in length, 19.6mm in width and 10mm in height. The chassis 6 is provided with a set of chassis slots 5, and the main body mold 1 is provided with a gap used in conjunction with the chassis slots 5. The main body mold 1 is installed and fixed on the chassis 6 through the chassis slots 5, and the middle of the top surface of the main body mold 1 The part is formed by mechanical wire cutting to form a hollowed-in recessed material pouring area 2, and the non-inset material pouring area on both sides is used for clamping of the wedge-shaped fixture of the SEM-serve equipment to ensure sufficient contact between the mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com